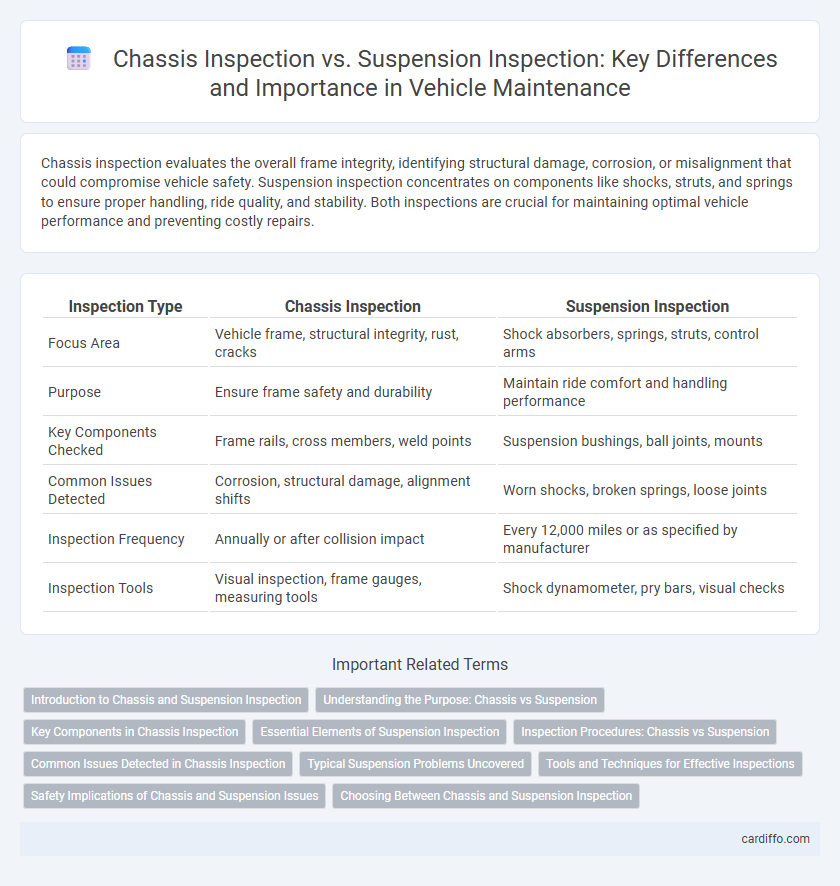

Chassis inspection evaluates the overall frame integrity, identifying structural damage, corrosion, or misalignment that could compromise vehicle safety. Suspension inspection concentrates on components like shocks, struts, and springs to ensure proper handling, ride quality, and stability. Both inspections are crucial for maintaining optimal vehicle performance and preventing costly repairs.

Table of Comparison

| Inspection Type | Chassis Inspection | Suspension Inspection |

|---|---|---|

| Focus Area | Vehicle frame, structural integrity, rust, cracks | Shock absorbers, springs, struts, control arms |

| Purpose | Ensure frame safety and durability | Maintain ride comfort and handling performance |

| Key Components Checked | Frame rails, cross members, weld points | Suspension bushings, ball joints, mounts |

| Common Issues Detected | Corrosion, structural damage, alignment shifts | Worn shocks, broken springs, loose joints |

| Inspection Frequency | Annually or after collision impact | Every 12,000 miles or as specified by manufacturer |

| Inspection Tools | Visual inspection, frame gauges, measuring tools | Shock dynamometer, pry bars, visual checks |

Introduction to Chassis and Suspension Inspection

Chassis inspection evaluates the vehicle's frame integrity, ensuring structural soundness and identifying corrosion or cracks that may compromise safety. Suspension inspection focuses on components like shocks, struts, springs, and control arms, assessing wear and alignment for proper handling and ride comfort. Both inspections are critical for vehicle performance, safety, and longevity, requiring detailed attention to different yet interconnected systems.

Understanding the Purpose: Chassis vs Suspension

Chassis inspection focuses on verifying the integrity of the vehicle's frame and structural components to ensure safety and durability, while suspension inspection targets the evaluation of shock absorbers, springs, and linkages that affect ride quality and handling. Understanding the purpose of chassis inspection involves detecting frame damage or corrosion that can compromise the vehicle's foundation. Suspension inspection aims to identify worn or damaged parts that influence vehicle stability, comfort, and alignment.

Key Components in Chassis Inspection

Chassis inspection focuses on key components such as the frame, cross members, welds, and mounting points for structural integrity and damage. Suspension inspection targets elements like shock absorbers, springs, control arms, and bushings to ensure proper vehicle handling and ride quality. Both inspections are crucial for overall vehicle safety, but chassis inspection primarily addresses the foundational support structure.

Essential Elements of Suspension Inspection

Suspension inspection centers on evaluating critical components such as shock absorbers, struts, control arms, and bushings for wear, leaks, and damage to ensure vehicle stability and ride comfort. Key elements include checking spring condition, ball joints, and wheel alignment to prevent uneven tire wear and maintain safe handling. Unlike chassis inspection, which emphasizes frame integrity and structural alignment, suspension inspection targets the dynamic parts affecting vehicle motion and safety.

Inspection Procedures: Chassis vs Suspension

Chassis inspection involves examining the frame, welds, and structural integrity to identify cracks, corrosion, or damage that could compromise vehicle safety. Suspension inspection focuses on checking components such as shock absorbers, springs, bushings, and control arms for wear, leaks, or alignment issues. Effective inspection procedures for both systems rely on visual assessments combined with hands-on testing methods like bounce, lift, and torque checks to ensure optimal vehicle stability and handling.

Common Issues Detected in Chassis Inspection

Chassis inspection commonly detects frame cracks, corrosion, and misalignment caused by impacts or wear, which can compromise vehicle safety and structural integrity. These inspections also identify issues like rust damage around mounting points and bent components that affect handling and stability. In contrast, suspension inspection primarily focuses on worn bushings, shock absorbers, and springs rather than the core structural problems revealed during a chassis inspection.

Typical Suspension Problems Uncovered

Suspension inspection typically reveals common issues such as worn-out shock absorbers, broken or sagging springs, and damaged bushings that affect vehicle stability and ride comfort. Chassis inspection, while broader, often misses these specific components prone to wear since it focuses more on frame integrity and structural damage. Identifying suspension problems early through targeted inspection prevents uneven tire wear and improves overall vehicle handling and safety.

Tools and Techniques for Effective Inspections

Chassis inspection utilizes precision measuring tools such as laser alignment systems and ultrasonic thickness gauges to detect structural integrity issues and potential frame deformation. Suspension inspection involves specialized equipment like dial indicators, spring compressors, and hydraulic jacks to accurately assess components including shocks, struts, and control arms for wear and proper function. Combining advanced diagnostic scanners with manual inspection techniques ensures comprehensive evaluation and timely maintenance of both chassis and suspension systems.

Safety Implications of Chassis and Suspension Issues

Chassis inspection ensures the structural integrity of a vehicle, identifying cracks or corrosion that could compromise overall safety during collisions. Suspension inspection detects worn or damaged components such as shocks, struts, and control arms, which directly affect vehicle stability, handling, and braking performance. Neglecting either inspection increases the risk of accidents due to potential mechanical failures and reduced control under dynamic driving conditions.

Choosing Between Chassis and Suspension Inspection

Choosing between chassis inspection and suspension inspection depends on the specific symptoms and vehicle issues observed. Chassis inspection focuses on the frame, structural integrity, and potential damage affecting the overall stability, while suspension inspection targets components such as shocks, struts, springs, and control arms essential for ride comfort and handling. Prioritizing a chassis inspection is critical after accidents or off-road use, whereas suspension inspection is vital when experiencing uneven tire wear, poor alignment, or unusual noises during driving.

Chassis inspection vs suspension inspection Infographic

cardiffo.com

cardiffo.com