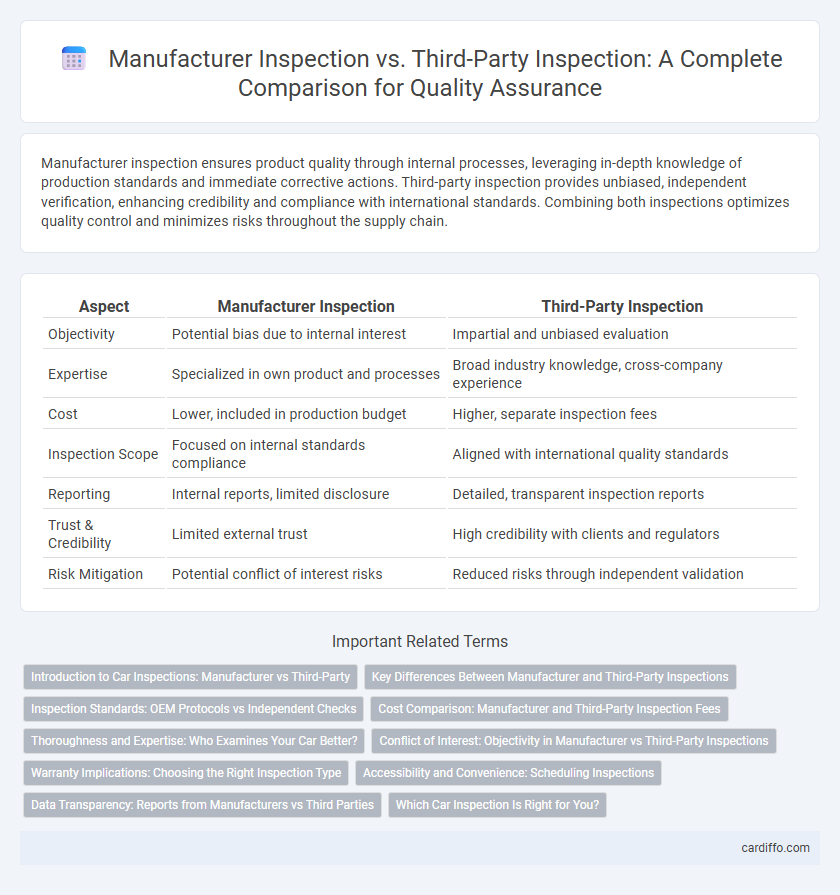

Manufacturer inspection ensures product quality through internal processes, leveraging in-depth knowledge of production standards and immediate corrective actions. Third-party inspection provides unbiased, independent verification, enhancing credibility and compliance with international standards. Combining both inspections optimizes quality control and minimizes risks throughout the supply chain.

Table of Comparison

| Aspect | Manufacturer Inspection | Third-Party Inspection |

|---|---|---|

| Objectivity | Potential bias due to internal interest | Impartial and unbiased evaluation |

| Expertise | Specialized in own product and processes | Broad industry knowledge, cross-company experience |

| Cost | Lower, included in production budget | Higher, separate inspection fees |

| Inspection Scope | Focused on internal standards compliance | Aligned with international quality standards |

| Reporting | Internal reports, limited disclosure | Detailed, transparent inspection reports |

| Trust & Credibility | Limited external trust | High credibility with clients and regulators |

| Risk Mitigation | Potential conflict of interest risks | Reduced risks through independent validation |

Introduction to Car Inspections: Manufacturer vs Third-Party

Manufacturer inspections are performed by the vehicle maker's trained technicians who follow specific guidelines to assess quality and compliance during production or pre-delivery stages. Third-party inspections are conducted by independent organizations that provide unbiased evaluations, ensuring an objective assessment of vehicle condition and adherence to safety standards. Choosing between manufacturer and third-party inspections depends on factors such as trustworthiness, cost, and the need for impartial verification in the car buying or maintenance process.

Key Differences Between Manufacturer and Third-Party Inspections

Manufacturer inspections are conducted by the producer's internal quality control team focused on ensuring compliance with proprietary standards and production specifications. Third-party inspections are performed by independent entities providing unbiased evaluations to verify product conformity and adherence to regulatory requirements. The key differences lie in objectivity, scope of inspection, and the level of trust associated with impartial validation versus internal quality assurance.

Inspection Standards: OEM Protocols vs Independent Checks

Manufacturer inspections adhere strictly to OEM protocols, ensuring products meet the original design specifications and quality benchmarks set by the manufacturer. Third-party inspections provide independent checks that enhance objectivity, verifying compliance with international standards such as ISO, and identifying defects or inconsistencies that may be overlooked. The contrast between OEM protocols and third-party inspections highlights the balance between proprietary quality control and unbiased conformity assessment.

Cost Comparison: Manufacturer and Third-Party Inspection Fees

Manufacturer inspection fees typically vary based on in-house resource allocation and operational scale, often resulting in lower direct costs for manufacturers familiar with their production processes. Third-party inspection fees usually involve higher charges due to specialized expertise, independent verification, and travel expenses, offering impartial quality assurance. Cost comparison reveals that while manufacturer inspections may reduce upfront expenses, third-party inspections provide valued transparency and risk reduction, justifying their premium fees in many industries.

Thoroughness and Expertise: Who Examines Your Car Better?

Manufacturer inspection leverages in-depth knowledge of specific car models, ensuring thorough checks aligned with original design and production standards. Third-party inspection offers unbiased expertise, often utilizing certified inspectors with broad experience across multiple brands and advanced diagnostic tools. Evaluating thoroughness and expertise depends on whether specialized manufacturer insight or comprehensive, independent assessment is prioritized for the vehicle's condition.

Conflict of Interest: Objectivity in Manufacturer vs Third-Party Inspections

Manufacturer inspections often face conflicts of interest due to their inherent connection with the production process, which can compromise the objectivity of quality assessments. Third-party inspections maintain greater impartiality by operating independently from manufacturers, ensuring more transparent and unbiased evaluation of products or processes. Objective third-party inspections enhance reliability and trustworthiness in compliance verification, mitigating risks associated with internal biases.

Warranty Implications: Choosing the Right Inspection Type

Manufacturer inspections often provide direct warranty validation, ensuring compliance with the original equipment specifications and reducing the risk of voided warranties. Third-party inspections offer unbiased assessments that can identify hidden defects but may sometimes lack direct warranty support from the manufacturer. Selecting the appropriate inspection type is critical to maintaining warranty coverage while ensuring product quality and reliability.

Accessibility and Convenience: Scheduling Inspections

Manufacturer inspections typically offer streamlined scheduling through direct communication channels, enabling quicker appointment setups and immediate access to technical expertise. Third-party inspections provide greater flexibility by accommodating diverse client timelines and locations, often utilizing digital platforms for booking and updates. Efficient scheduling systems in both approaches enhance overall inspection accessibility and reduce downtime in production.

Data Transparency: Reports from Manufacturers vs Third Parties

Reports from manufacturers often emphasize proprietary data that may lack full transparency, as the information primarily serves internal quality assurance and brand reputation. Third-party inspections provide unbiased, detailed reports with standardized data formats that enhance credibility and facilitate comparison across different suppliers or production batches. Independent verification through third-party inspection increases confidence in data accuracy and objectivity, supporting better decision-making in quality control processes.

Which Car Inspection Is Right for You?

Choosing between manufacturer inspection and third-party inspection depends on your priorities and the level of objectivity you seek. Manufacturer inspections often provide detailed assessments aligned with brand standards, ideal for warranty compliance and specialized repairs. Third-party inspections offer unbiased evaluations, beneficial for used car purchases or when an independent opinion is crucial for vehicle condition verification.

Manufacturer inspection vs third-party inspection Infographic

cardiffo.com

cardiffo.com