Static inspection involves analyzing code or systems without executing them, identifying errors, vulnerabilities, or compliance issues through techniques like code review or static analysis tools. Dynamic inspection, by contrast, entails examining the system during runtime to detect faults and performance bottlenecks through testing or monitoring. Combining both methods enhances the reliability and security of software by covering different aspects of potential defects.

Table of Comparison

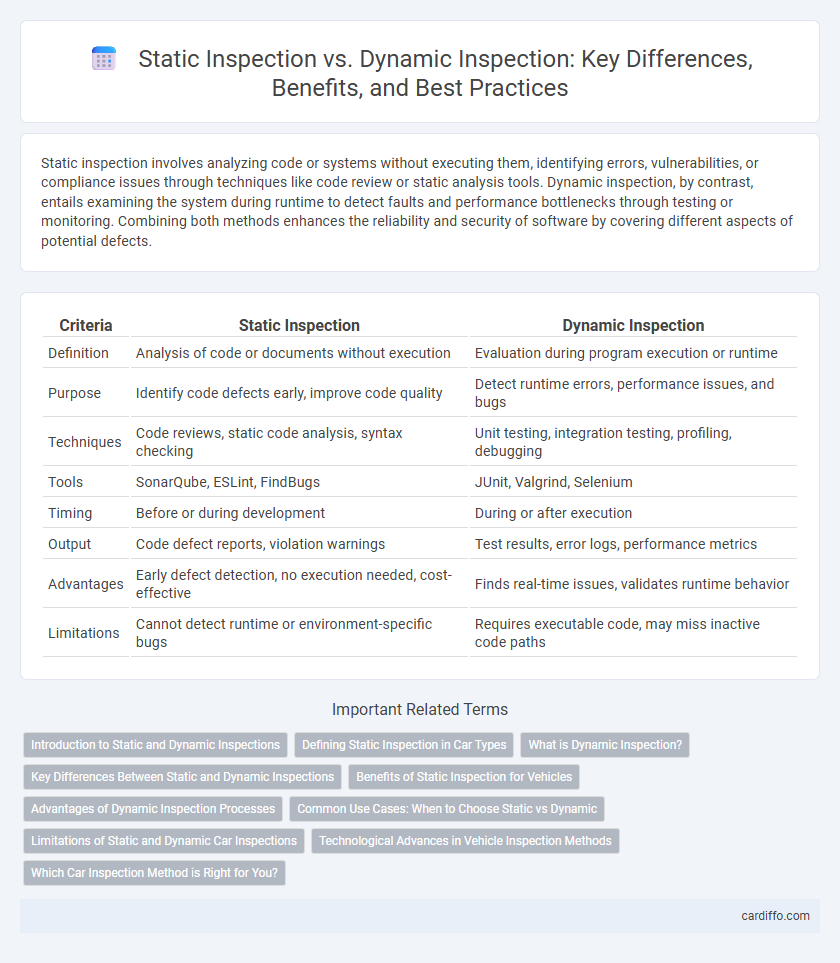

| Criteria | Static Inspection | Dynamic Inspection |

|---|---|---|

| Definition | Analysis of code or documents without execution | Evaluation during program execution or runtime |

| Purpose | Identify code defects early, improve code quality | Detect runtime errors, performance issues, and bugs |

| Techniques | Code reviews, static code analysis, syntax checking | Unit testing, integration testing, profiling, debugging |

| Tools | SonarQube, ESLint, FindBugs | JUnit, Valgrind, Selenium |

| Timing | Before or during development | During or after execution |

| Output | Code defect reports, violation warnings | Test results, error logs, performance metrics |

| Advantages | Early defect detection, no execution needed, cost-effective | Finds real-time issues, validates runtime behavior |

| Limitations | Cannot detect runtime or environment-specific bugs | Requires executable code, may miss inactive code paths |

Introduction to Static and Dynamic Inspections

Static inspection analyzes code or documents without executing the program, enabling early detection of errors, code standards violations, and security vulnerabilities through techniques like code reviews and static analysis tools. Dynamic inspection involves executing the program with test cases to observe its behavior, uncover runtime errors, performance issues, and memory leaks using debugging and profiling methods. Both inspection types play crucial roles in software quality assurance by providing complementary insights that enhance code reliability and maintainability.

Defining Static Inspection in Car Types

Static inspection in car types involves examining vehicles without operating the engine or requiring movement, focusing on structural integrity, electrical systems, and component conditions. This inspection method identifies defects such as corrosion, leaks, and wear in brakes, tires, and bodywork through visual checks and diagnostic tools. Emphasizing non-invasive techniques, static inspections ensure compliance with safety and regulatory standards before dynamic testing occurs.

What is Dynamic Inspection?

Dynamic inspection is a software testing process that evaluates code behavior by executing programs in a runtime environment, identifying defects through real-time analysis. This method captures issues such as memory leaks, performance bottlenecks, and runtime errors that static inspection cannot detect. By analyzing the software during execution, dynamic inspection provides insights into system interactions, resource utilization, and functional correctness.

Key Differences Between Static and Dynamic Inspections

Static inspection analyzes code without executing it, identifying syntax errors, code smells, and potential vulnerabilities early in the development process. Dynamic inspection involves running the program to observe its behavior, detecting runtime errors, performance bottlenecks, and security issues under real execution conditions. The key difference lies in static inspection's focus on code structure and quality versus dynamic inspection's emphasis on actual program execution and behavior validation.

Benefits of Static Inspection for Vehicles

Static inspection of vehicles offers the advantage of a thorough assessment without requiring engine operation, reducing safety risks and minimizing environmental impact. It enables early detection of defects in critical components such as brakes, tires, and structural integrity, ensuring vehicle compliance with safety standards. Static inspection also allows inspectors to identify potential issues in electronic systems through diagnostic tools, enhancing preventive maintenance and reducing downtime.

Advantages of Dynamic Inspection Processes

Dynamic inspection processes enable real-time detection of defects during product operation, significantly improving accuracy compared to static inspection methods. They provide detailed insights into system behavior under actual working conditions, enhancing fault diagnosis and reducing downtime. This approach supports continuous monitoring and immediate feedback, leading to higher reliability and optimized maintenance schedules.

Common Use Cases: When to Choose Static vs Dynamic

Static inspection is ideal for identifying vulnerabilities in source code, such as syntax errors, code quality issues, and security flaws, before program execution, making it essential for early-stage development and code reviews. Dynamic inspection excels in detecting runtime errors, memory leaks, and performance bottlenecks through real-time testing and monitoring, often used during quality assurance and system testing phases. Choosing static inspection suits scenarios requiring early error detection, while dynamic inspection is preferred for validating system behavior and performance under actual operating conditions.

Limitations of Static and Dynamic Car Inspections

Static car inspections often miss real-time operational issues because they evaluate vehicles without engine running or during non-driving conditions, limiting detection of dynamic faults like overheating or transmission slipping. Dynamic inspections provide more comprehensive diagnostics under actual driving conditions but can be constrained by environmental factors, inconsistent test routes, and the need for specialized equipment or trained personnel. Both methods may fail to identify intermittent or sensor-related problems without integrated data analysis and prolonged observation.

Technological Advances in Vehicle Inspection Methods

Technological advances have revolutionized vehicle inspection methods by integrating both static and dynamic inspection techniques for enhanced accuracy and efficiency. Static inspection uses advanced sensory devices and AI algorithms to analyze vehicle components without movement, identifying issues such as emissions or mechanical wear. Dynamic inspection incorporates real-time data from on-road sensors and diagnostic tools, enabling detection of performance-related problems under actual driving conditions.

Which Car Inspection Method is Right for You?

Static inspection involves evaluating a vehicle's components and systems while it is stationary, focusing on visual checks and diagnostic tests to identify faults without operation. Dynamic inspection tests the car under real driving conditions, assessing performance, handling, and functionality during motion to detect issues that are not visible at rest. Choosing the right car inspection method depends on the vehicle's age, usage patterns, and specific concerns, with static inspection suitable for routine maintenance and dynamic inspection essential for comprehensive performance evaluation.

Static inspection vs Dynamic inspection Infographic

cardiffo.com

cardiffo.com