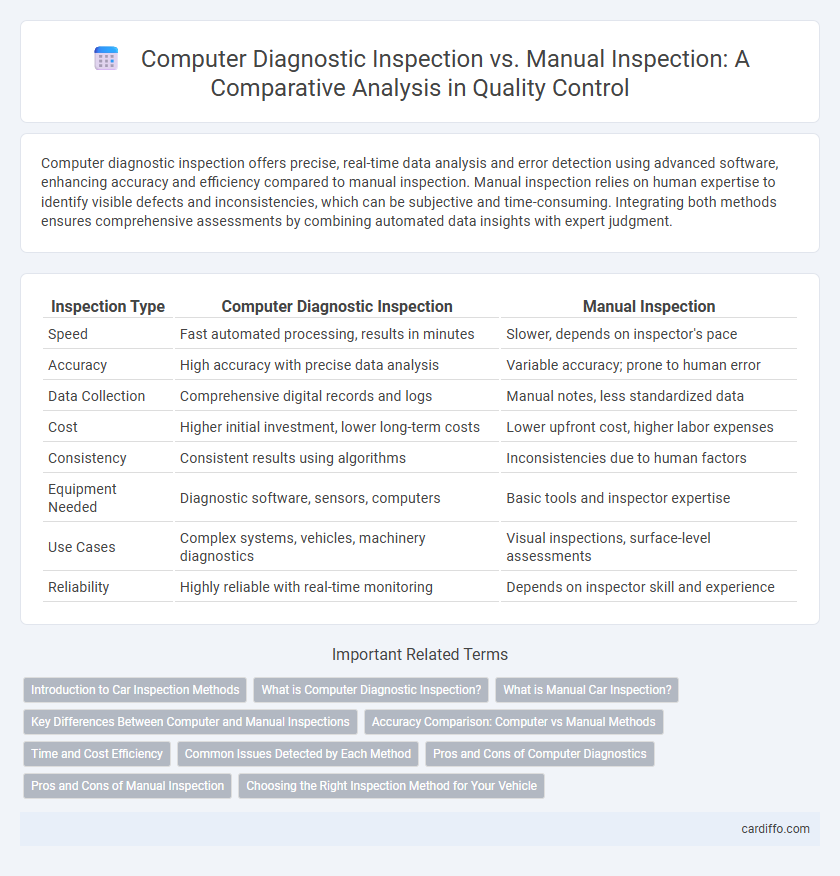

Computer diagnostic inspection offers precise, real-time data analysis and error detection using advanced software, enhancing accuracy and efficiency compared to manual inspection. Manual inspection relies on human expertise to identify visible defects and inconsistencies, which can be subjective and time-consuming. Integrating both methods ensures comprehensive assessments by combining automated data insights with expert judgment.

Table of Comparison

| Inspection Type | Computer Diagnostic Inspection | Manual Inspection |

|---|---|---|

| Speed | Fast automated processing, results in minutes | Slower, depends on inspector's pace |

| Accuracy | High accuracy with precise data analysis | Variable accuracy; prone to human error |

| Data Collection | Comprehensive digital records and logs | Manual notes, less standardized data |

| Cost | Higher initial investment, lower long-term costs | Lower upfront cost, higher labor expenses |

| Consistency | Consistent results using algorithms | Inconsistencies due to human factors |

| Equipment Needed | Diagnostic software, sensors, computers | Basic tools and inspector expertise |

| Use Cases | Complex systems, vehicles, machinery diagnostics | Visual inspections, surface-level assessments |

| Reliability | Highly reliable with real-time monitoring | Depends on inspector skill and experience |

Introduction to Car Inspection Methods

Computer diagnostic inspection utilizes advanced electronic systems and software to quickly identify car issues by analyzing sensor data and onboard diagnostics, providing precise fault codes and system status. Manual inspection relies on a trained technician's physical examination and sensory evaluation to detect visible wear, leaks, or sound anomalies, offering insights that computerized systems might overlook. Combining both methods enhances overall accuracy and ensures a comprehensive vehicle assessment.

What is Computer Diagnostic Inspection?

Computer diagnostic inspection uses specialized software and hardware tools to analyze and identify issues in systems or machinery with high precision and speed. This method relies on sensor data, error codes, and automated testing algorithms to detect faults that may be missed in manual inspections. It enhances accuracy, reduces human error, and provides detailed diagnostics reports for efficient troubleshooting and maintenance.

What is Manual Car Inspection?

Manual car inspection involves a hands-on examination of a vehicle's physical components, such as the engine, brakes, suspension, and bodywork, performed by a trained technician. This method relies on visual checks, tactile feedback, and mechanical testing to identify wear, damage, or faults that may not be detected by computer diagnostics. Manual inspection is crucial for assessing issues related to vehicle performance, safety, and structural integrity that computerized scans may overlook.

Key Differences Between Computer and Manual Inspections

Computer diagnostic inspections offer higher accuracy and speed by using advanced sensors and software algorithms to detect faults that manual inspections might overlook. Manual inspections rely on human expertise and visual assessment, making them subjective and prone to errors but effective for identifying subtle or unexpected issues. Key differences include data collection methods, consistency, and the ability to detect complex or hidden defects, with computer diagnostics providing quantifiable results and manual inspections depending on inspector experience.

Accuracy Comparison: Computer vs Manual Methods

Computer diagnostic inspection offers higher accuracy than manual inspection by utilizing advanced sensors, machine learning algorithms, and real-time data analysis to detect defects with minimal human error. Manual inspection depends heavily on the inspector's experience and can be prone to inconsistencies, fatigue, and subjectivity, leading to variable precision levels. Studies show computer-assisted inspections achieve defect detection rates exceeding 95%, whereas manual methods average significantly lower accuracy, often below 80%.

Time and Cost Efficiency

Computer diagnostic inspection significantly reduces inspection time by automating data collection and analysis, enabling rapid detection of faults compared to manual inspection. Cost efficiency improves as computer diagnostics minimize labor expenses and reduce the likelihood of human error-related rework. This technology streamlines the inspection process, delivering faster results and lower operational costs in quality control environments.

Common Issues Detected by Each Method

Computer diagnostic inspections efficiently detect engine misfires, sensor malfunctions, and electronic control unit errors using precise data analysis and real-time monitoring. Manual inspections excel in identifying physical damage, fluid leaks, and worn mechanical components through tactile evaluation and visual assessment. Combining both methods ensures comprehensive identification of vehicle issues, enhancing accuracy in maintenance and repair diagnostics.

Pros and Cons of Computer Diagnostics

Computer diagnostic inspection offers rapid and precise identification of system errors using advanced algorithms and sensor data, reducing human error and downtime in maintenance processes. However, it may overlook nuanced issues detectable only through hands-on manual inspection, and initial setup costs for diagnostic equipment can be high. Reliance on software also risks missing mechanical faults outside programmed parameters, necessitating complementary manual checks for comprehensive system evaluation.

Pros and Cons of Manual Inspection

Manual inspection allows for flexible assessment of complex or irregular components that automated systems may miss, leveraging human judgment and experience. It can identify subtle defects, surface texture variations, or assembly issues not easily captured by computer diagnostics, though it is labor-intensive and prone to human error or inconsistency. Despite limitations in speed and repeatability compared to automated inspections, manual inspection remains essential for quality assurance in scenarios requiring nuanced evaluation and tactile feedback.

Choosing the Right Inspection Method for Your Vehicle

Computer diagnostic inspection offers precise fault detection by analyzing real-time data from the vehicle's onboard computer system, enabling quick identification of engine, transmission, and electronic issues. Manual inspection relies on physical examination and mechanical expertise, suitable for assessing wear, corrosion, and components not covered by diagnostic codes. Selecting the right method depends on the vehicle's age, complexity, and the specific symptoms presented, ensuring an accurate and efficient inspection process.

Computer diagnostic inspection vs manual inspection Infographic

cardiffo.com

cardiffo.com