Detailed inspections involve thorough examination of every component to identify potential issues that might be overlooked during a quick assessment. Cursory inspections, while faster, often miss critical defects or irregularities that can lead to equipment failure or safety hazards. Prioritizing detailed inspections enhances reliability and ensures compliance with industry standards.

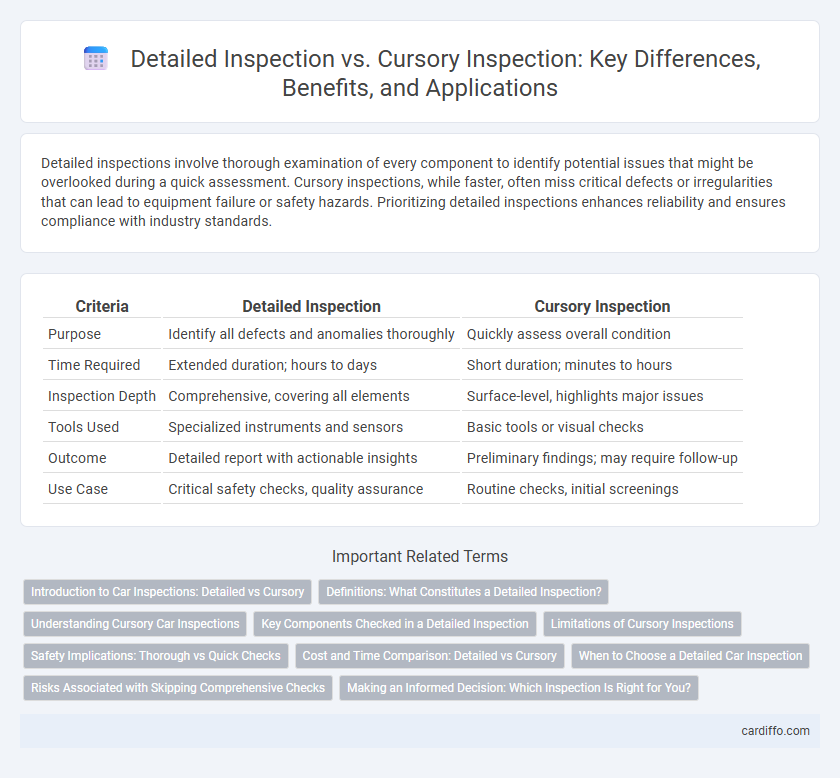

Table of Comparison

| Criteria | Detailed Inspection | Cursory Inspection |

|---|---|---|

| Purpose | Identify all defects and anomalies thoroughly | Quickly assess overall condition |

| Time Required | Extended duration; hours to days | Short duration; minutes to hours |

| Inspection Depth | Comprehensive, covering all elements | Surface-level, highlights major issues |

| Tools Used | Specialized instruments and sensors | Basic tools or visual checks |

| Outcome | Detailed report with actionable insights | Preliminary findings; may require follow-up |

| Use Case | Critical safety checks, quality assurance | Routine checks, initial screenings |

Introduction to Car Inspections: Detailed vs Cursory

Detailed inspections involve a comprehensive evaluation of a vehicle's components, including engine performance, brake systems, and structural integrity, ensuring safety and compliance with regulations. Cursory inspections provide a quick overview, focusing on visible damages and basic functionality without in-depth analysis. Understanding the differences between detailed and cursory car inspections helps in determining the appropriate level of assessment for maintenance, resale, or safety checks.

Definitions: What Constitutes a Detailed Inspection?

A detailed inspection involves a thorough and systematic examination of all components, systems, or areas to identify defects, wear, or non-compliance with standards, often requiring specialized tools and expertise. It contrasts with a cursory inspection, which is a quick, surface-level check aimed at identifying obvious issues without delving into underlying problems. Detailed inspections are essential for ensuring safety, reliability, and regulatory compliance in industries such as aviation, manufacturing, and construction.

Understanding Cursory Car Inspections

Cursory car inspections involve a quick visual assessment to identify obvious issues such as fluid leaks, tire condition, and exterior damage, providing a preliminary overview of the vehicle's state. These inspections typically take 10-15 minutes and do not include in-depth diagnostic testing or component dismantling. While detailed inspections thoroughly evaluate every system for safety and functionality, cursory inspections serve as efficient initial screenings to prioritize vehicles needing comprehensive evaluation.

Key Components Checked in a Detailed Inspection

Detailed inspections thoroughly examine critical components such as structural integrity, electrical systems, and safety mechanisms, ensuring each element meets regulatory standards and operational efficiency. This contrasts with cursory inspections that only assess surface conditions and obvious defects. Key components in detailed inspections include load-bearing structures, wiring insulation, mechanical parts, and safety equipment functionality to prevent failures and extend asset lifespan.

Limitations of Cursory Inspections

Cursory inspections often overlook critical defects or subtle irregularities due to their rapid and superficial nature, increasing the risk of undetected safety hazards or compliance issues. Unlike detailed inspections, they lack thorough documentation and objective measurements, limiting their effectiveness in complex or high-stakes environments such as aerospace or structural engineering. Reliance on cursory inspections can result in costly rework, legal liabilities, and compromised operational integrity.

Safety Implications: Thorough vs Quick Checks

Detailed inspections involve comprehensive evaluations that identify potential safety hazards and ensure compliance with regulations, significantly reducing the risk of accidents and system failures. Cursory inspections, while faster, may overlook critical issues, increasing the likelihood of undetected safety risks and operational hazards. Prioritizing thorough inspections enhances workplace safety and equipment reliability by addressing all possible fault points.

Cost and Time Comparison: Detailed vs Cursory

Detailed inspections require significantly more time and labor costs compared to cursory inspections, as they involve comprehensive examination and thorough documentation. While cursory inspections are faster and less expensive, they risk overlooking critical issues that can lead to higher expenses in future repairs or safety failures. Investing in detailed inspections reduces long-term costs by identifying defects early, preventing costly downtime and extensive damage.

When to Choose a Detailed Car Inspection

Choose a detailed car inspection when assessing high-value vehicles, post-accident evaluations, or before long-term ownership to identify hidden issues not visible during a cursory inspection. This thorough process includes comprehensive checks of the engine, transmission, suspension, and electronic systems, providing a complete condition report. Detailed inspections are essential for ensuring reliability, safety, and accurate resale valuation.

Risks Associated with Skipping Comprehensive Checks

Skipping comprehensive checks during inspections significantly increases the risk of overlooking critical defects, which can lead to equipment failure or safety hazards. Detailed inspections identify subtle wear and tear, corrosion, or technical anomalies that cursory inspections often miss. Relying solely on quick assessments compromises operational integrity and elevates the likelihood of costly downtime and regulatory non-compliance.

Making an Informed Decision: Which Inspection Is Right for You?

Detailed inspection offers a thorough evaluation of components, identifying hidden defects and ensuring comprehensive risk assessment, ideal for high-value or safety-critical assets. Cursory inspection provides a quick overview, suitable for routine checks or preliminary assessments where time and resources are limited. Choosing the right inspection depends on the asset's importance, condition, and the level of confidence required for informed decision-making.

Detailed inspection vs cursory inspection Infographic

cardiffo.com

cardiffo.com