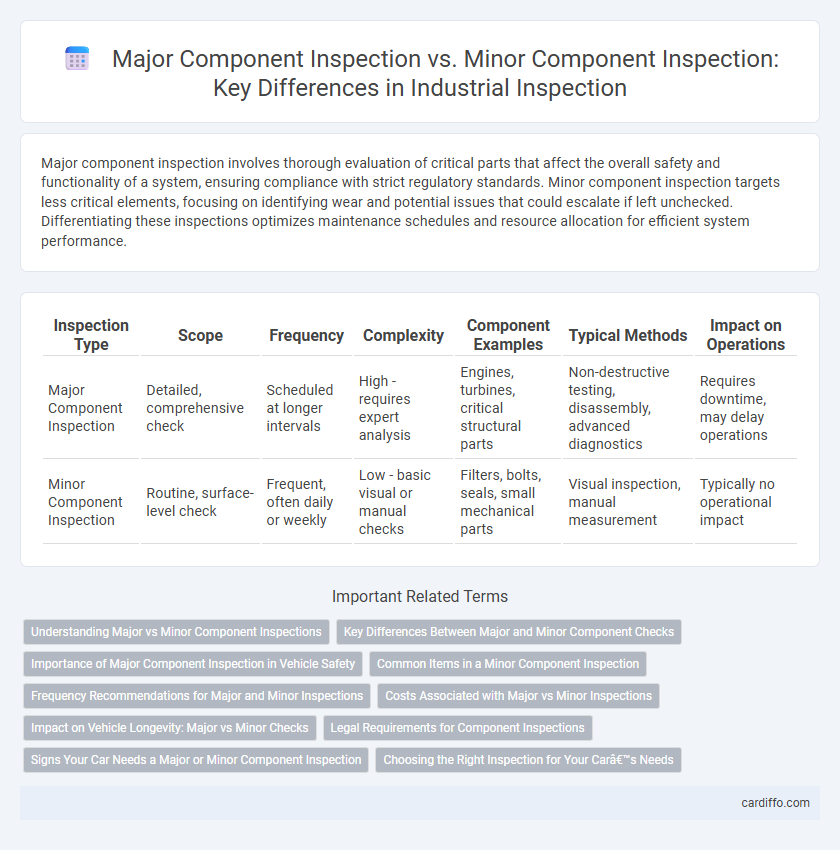

Major component inspection involves thorough evaluation of critical parts that affect the overall safety and functionality of a system, ensuring compliance with strict regulatory standards. Minor component inspection targets less critical elements, focusing on identifying wear and potential issues that could escalate if left unchecked. Differentiating these inspections optimizes maintenance schedules and resource allocation for efficient system performance.

Table of Comparison

| Inspection Type | Scope | Frequency | Complexity | Component Examples | Typical Methods | Impact on Operations |

|---|---|---|---|---|---|---|

| Major Component Inspection | Detailed, comprehensive check | Scheduled at longer intervals | High - requires expert analysis | Engines, turbines, critical structural parts | Non-destructive testing, disassembly, advanced diagnostics | Requires downtime, may delay operations |

| Minor Component Inspection | Routine, surface-level check | Frequent, often daily or weekly | Low - basic visual or manual checks | Filters, bolts, seals, small mechanical parts | Visual inspection, manual measurement | Typically no operational impact |

Understanding Major vs Minor Component Inspections

Major component inspection involves a detailed evaluation of critical systems and parts that directly impact the overall safety and functionality of equipment, such as engines, structural elements, and control systems. Minor component inspection targets less critical elements like bolts, sensors, and auxiliary systems to ensure basic operational integrity without extensive disassembly. Understanding the distinction between these inspections is essential for prioritizing maintenance efforts, optimizing downtime, and maintaining regulatory compliance.

Key Differences Between Major and Minor Component Checks

Major component inspection involves thorough evaluation of critical systems such as engines, landing gear, and avionics, ensuring overall safety and functionality. Minor component inspection focuses on less critical parts including panel fasteners, wiring harnesses, and access doors, primarily targeting wear and tear or minor defects. The key differences lie in inspection depth, consequences of failure, and maintenance intervals, with major checks requiring extensive disassembly and certification.

Importance of Major Component Inspection in Vehicle Safety

Major component inspection plays a crucial role in vehicle safety by ensuring critical parts such as brakes, suspension, and steering systems function optimally, reducing the risk of accidents caused by mechanical failure. Unlike minor component inspections that cover less critical items, major inspections focus on components that directly impact the vehicle's structural integrity and control. Thorough assessment of these key systems helps maintain roadworthiness, prevent costly repairs, and enhance overall driver and passenger protection.

Common Items in a Minor Component Inspection

Common items in a minor component inspection typically include fasteners, seals, gaskets, hoses, and electrical connectors. These elements are crucial for maintaining system integrity and preventing leaks or failures in everyday operation. Inspections concentrate on wear, corrosion, and proper installation to ensure minor components support the overall functionality of major systems.

Frequency Recommendations for Major and Minor Inspections

Major component inspections are recommended at longer intervals, typically every 12 to 24 months, due to their critical impact on system safety and performance. Minor component inspections should be conducted more frequently, often every 3 to 6 months, to identify wear or potential failures early. Adhering to these frequency recommendations ensures optimal maintenance schedules and reduces the risk of unexpected breakdowns.

Costs Associated with Major vs Minor Inspections

Major component inspections typically incur higher costs due to the extensive labor, specialized tools, and potential downtime required for thorough assessment and repairs. Minor component inspections generally involve lower expenses, focusing on routine checks with minimal disruption and less specialized equipment. Cost efficiency can be optimized by scheduling major inspections strategically to prevent costly failures and extending intervals between minor inspections where possible.

Impact on Vehicle Longevity: Major vs Minor Checks

Major component inspections target critical systems such as the engine, transmission, and brakes, significantly extending vehicle longevity by identifying serious wear and preventing catastrophic failures. Minor component inspections focus on routine checks like fluid levels, filters, and minor electrical systems, supporting overall maintenance and ensuring consistent performance. Combining major and minor inspection schedules optimizes vehicle lifespan by addressing both critical and preventive care needs.

Legal Requirements for Component Inspections

Legal requirements for major component inspections typically mandate detailed documentation, certified inspectors, and adherence to stringent regulatory standards such as FAA or EASA guidelines. Minor component inspections, while legally required, often follow less rigorous protocols, emphasizing functional checks and visual assessments without extensive certification processes. Compliance ensures safety, prevents liability, and is enforced through regular audits and certification renewals by authorized agencies.

Signs Your Car Needs a Major or Minor Component Inspection

Visible wear such as cracks, leaks, or corrosion on critical parts like brake pads, suspension, or engine components signals the need for a major component inspection. Warning lights on the dashboard, unusual noises, or minor issues like loose fittings and small fluid leaks may indicate that a minor component inspection is necessary. Timely identification of these signs ensures safety, prevents costly repairs, and maintains optimal vehicle performance.

Choosing the Right Inspection for Your Car’s Needs

Major component inspection targets critical parts such as the engine, transmission, and braking systems, ensuring the vehicle's core safety and performance. Minor component inspection focuses on less critical elements like lights, tires, and fluid levels, helping maintain everyday functionality and prevent early wear. Selecting the appropriate inspection depends on your vehicle's age, mileage, and specific symptoms, optimizing safety and cost-efficiency.

Major Component Inspection vs Minor Component Inspection Infographic

cardiffo.com

cardiffo.com