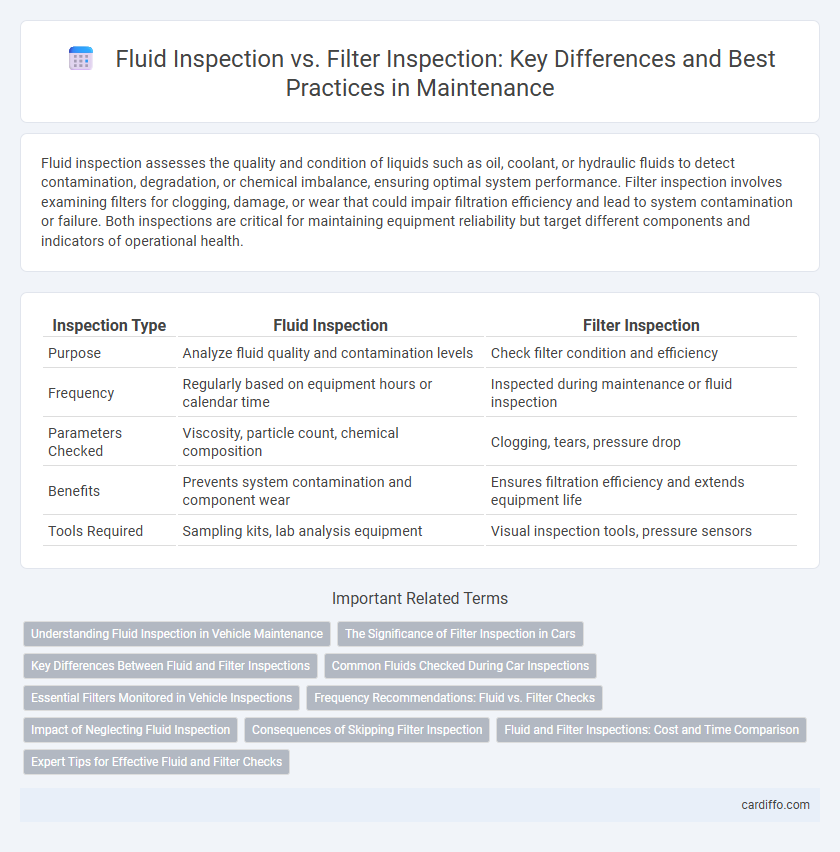

Fluid inspection assesses the quality and condition of liquids such as oil, coolant, or hydraulic fluids to detect contamination, degradation, or chemical imbalance, ensuring optimal system performance. Filter inspection involves examining filters for clogging, damage, or wear that could impair filtration efficiency and lead to system contamination or failure. Both inspections are critical for maintaining equipment reliability but target different components and indicators of operational health.

Table of Comparison

| Inspection Type | Fluid Inspection | Filter Inspection |

|---|---|---|

| Purpose | Analyze fluid quality and contamination levels | Check filter condition and efficiency |

| Frequency | Regularly based on equipment hours or calendar time | Inspected during maintenance or fluid inspection |

| Parameters Checked | Viscosity, particle count, chemical composition | Clogging, tears, pressure drop |

| Benefits | Prevents system contamination and component wear | Ensures filtration efficiency and extends equipment life |

| Tools Required | Sampling kits, lab analysis equipment | Visual inspection tools, pressure sensors |

Understanding Fluid Inspection in Vehicle Maintenance

Fluid inspection in vehicle maintenance involves analyzing the condition and quality of engine oil, coolant, transmission fluid, and brake fluid to ensure optimal performance and prevent engine wear or overheating. Unlike filter inspection, which focuses on checking and replacing air, oil, or fuel filters to maintain cleanliness and flow, fluid inspection detects contamination, degradation, or leaks early, safeguarding engine components and extending vehicle lifespan. Regular fluid analysis using tools like dipsticks, refractometers, or onboard sensors enhances predictive maintenance and reduces the risk of costly repairs.

The Significance of Filter Inspection in Cars

Filter inspection in cars is crucial for maintaining engine performance and prolonging vehicle lifespan by ensuring contaminants are effectively removed from fluids such as oil or fuel. Unlike general fluid inspection, which assesses fluid condition and levels, filter inspection specifically targets the filtration system's efficiency in trapping debris and preventing engine damage. Regular filter checks help avoid costly repairs and optimize fuel efficiency by sustaining clean fluid circulation within the engine.

Key Differences Between Fluid and Filter Inspections

Fluid inspection primarily involves analyzing the chemical composition, contamination levels, and physical properties of lubricants or hydraulic fluids to ensure proper machinery performance. Filter inspection focuses on evaluating filter media for blockage, particle accumulation, and structural integrity to maintain effective filtration and prevent system damage. Understanding these differences is crucial for predictive maintenance and optimizing equipment reliability.

Common Fluids Checked During Car Inspections

Common fluids checked during car inspections include engine oil, coolant, brake fluid, transmission fluid, and power steering fluid, each crucial for vehicle performance and safety. Fluid inspection ensures proper levels, contamination-free condition, and timely replacement to prevent engine damage, overheating, brake failure, and steering issues. Filter inspection, on the other hand, focuses on air, oil, and fuel filters to maintain fluid cleanliness and protect engine components from debris and wear.

Essential Filters Monitored in Vehicle Inspections

Essential filters monitored in vehicle inspections include oil filters, fuel filters, air filters, and cabin air filters, each playing a crucial role in maintaining engine performance and cabin air quality. Fluid inspection primarily evaluates the condition and quality of engine oil, coolant, brake fluid, and transmission fluid to prevent wear and system failures. Filter inspection focuses on identifying clogging, damage, or contamination that can impair filtration efficiency and increase engine strain.

Frequency Recommendations: Fluid vs. Filter Checks

Fluid inspection frequency typically requires monthly or quarterly analysis to detect contamination and maintain system performance, whereas filter inspection often demands more frequent checks, sometimes weekly, to ensure debris accumulation does not impair functionality. Industry guidelines recommend matching fluid sampling intervals with operational hours or mileage, while filter inspections are aligned with pressure drop limits or visual clogging indicators. Optimizing inspection schedules based on equipment type and environmental conditions enhances preventive maintenance effectiveness and reduces downtime risks.

Impact of Neglecting Fluid Inspection

Neglecting fluid inspection can lead to severe contamination issues that compromise system performance and accelerate wear in hydraulic and lubrication systems. Unlike filter inspection that primarily targets particulate removal, fluid inspection detects chemical degradation, contamination levels, and viscosity changes critical for early fault diagnosis. Failing to monitor fluid quality increases the risk of equipment breakdown, reduces operational efficiency, and results in costly repairs or downtime.

Consequences of Skipping Filter Inspection

Skipping filter inspection can lead to clogged or damaged filters, resulting in reduced fluid flow and increased system contamination. Contaminants bypassing uninspected filters can cause accelerated wear and potential failure of critical components, leading to costly repairs and downtime. Regular filter inspection is essential to maintain fluid cleanliness, ensure optimal system performance, and extend equipment lifespan.

Fluid and Filter Inspections: Cost and Time Comparison

Fluid inspection typically requires less time and lower costs compared to filter inspection, as it involves analyzing fluid samples for contaminants or degradation using automated sensors or laboratory testing. Filter inspection demands more labor-intensive procedures, including visual examination, disassembly, and sometimes replacement, leading to higher operational expenses and longer downtime. Balancing fluid and filter inspections optimizes maintenance budgets by targeting critical issues efficiently while minimizing inspection frequencies and associated costs.

Expert Tips for Effective Fluid and Filter Checks

Expert tips for effective fluid and filter inspections emphasize the importance of checking fluid levels, consistency, and contamination signs to maintain optimal machinery performance. Filters should be examined for clogging, damage, and proper installation to ensure efficient filtration and prevent system failures. Regularly scheduled fluid sampling combined with filter integrity tests enhances early detection of potential issues, reducing downtime and repair costs.

Fluid inspection vs filter inspection Infographic

cardiffo.com

cardiffo.com