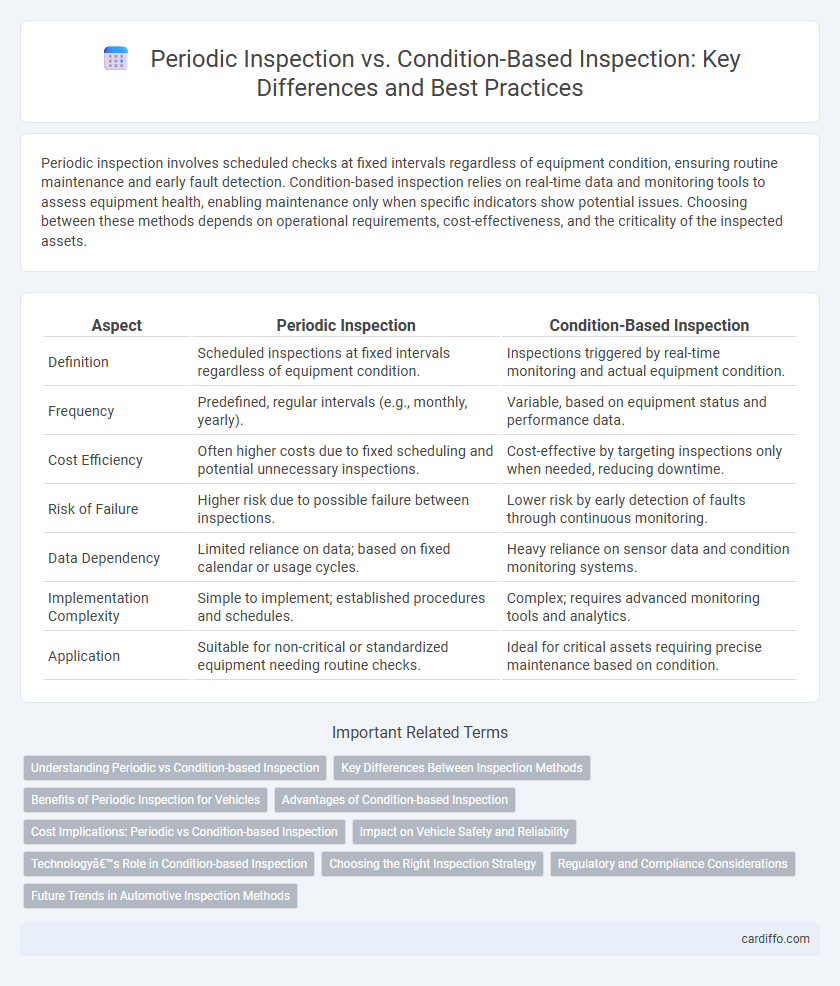

Periodic inspection involves scheduled checks at fixed intervals regardless of equipment condition, ensuring routine maintenance and early fault detection. Condition-based inspection relies on real-time data and monitoring tools to assess equipment health, enabling maintenance only when specific indicators show potential issues. Choosing between these methods depends on operational requirements, cost-effectiveness, and the criticality of the inspected assets.

Table of Comparison

| Aspect | Periodic Inspection | Condition-Based Inspection |

|---|---|---|

| Definition | Scheduled inspections at fixed intervals regardless of equipment condition. | Inspections triggered by real-time monitoring and actual equipment condition. |

| Frequency | Predefined, regular intervals (e.g., monthly, yearly). | Variable, based on equipment status and performance data. |

| Cost Efficiency | Often higher costs due to fixed scheduling and potential unnecessary inspections. | Cost-effective by targeting inspections only when needed, reducing downtime. |

| Risk of Failure | Higher risk due to possible failure between inspections. | Lower risk by early detection of faults through continuous monitoring. |

| Data Dependency | Limited reliance on data; based on fixed calendar or usage cycles. | Heavy reliance on sensor data and condition monitoring systems. |

| Implementation Complexity | Simple to implement; established procedures and schedules. | Complex; requires advanced monitoring tools and analytics. |

| Application | Suitable for non-critical or standardized equipment needing routine checks. | Ideal for critical assets requiring precise maintenance based on condition. |

Understanding Periodic vs Condition-based Inspection

Periodic inspection involves scheduled assessments at fixed intervals to ensure equipment reliability and compliance with safety standards, minimizing unexpected failures. Condition-based inspection relies on real-time data and monitoring technologies, such as vibration analysis and thermal imaging, to evaluate asset health and optimize maintenance timing. Understanding the differences between these approaches enables organizations to balance maintenance costs with operational efficiency and equipment lifespan.

Key Differences Between Inspection Methods

Periodic inspection involves scheduled evaluations at fixed intervals regardless of equipment condition, ensuring routine maintenance and compliance with regulatory standards. Condition-based inspection relies on real-time data and monitoring techniques, such as vibration analysis and thermal imaging, to assess asset health and trigger inspections only when specific indicators show potential failure. This key difference highlights the proactive nature of condition-based inspection versus the preventive approach of periodic inspection, optimizing maintenance costs and reducing unexpected downtime.

Benefits of Periodic Inspection for Vehicles

Periodic inspection for vehicles ensures consistent safety and compliance by scheduling regular checks regardless of current condition, which helps identify potential issues before they escalate. This proactive approach reduces the risk of unexpected breakdowns and extends vehicle lifespan through routine maintenance. Standardized intervals also simplify regulatory adherence and provide clear guidelines for fleet management.

Advantages of Condition-based Inspection

Condition-based inspection offers significant advantages by utilizing real-time data and sensor monitoring to detect equipment anomalies early, reducing unplanned downtime and maintenance costs. It enables targeted maintenance interventions based on actual equipment condition rather than fixed schedules, enhancing asset reliability and extending equipment lifespan. This approach optimizes resource allocation and minimizes unnecessary inspections, improving operational efficiency and safety in industrial environments.

Cost Implications: Periodic vs Condition-based Inspection

Periodic inspection typically involves fixed scheduling regardless of equipment condition, leading to predictable but potentially higher maintenance costs due to unnecessary checks and part replacements. Condition-based inspection relies on real-time data and monitoring, reducing costs by targeting maintenance only when indicators show deterioration or failure risk. Overall, condition-based inspection optimizes resource allocation and lowers total expenditure by minimizing downtime and avoiding over-maintenance.

Impact on Vehicle Safety and Reliability

Periodic inspection ensures vehicle safety and reliability by scheduling maintenance at fixed intervals, preventing unexpected failures through routine checks. Condition-based inspection improves safety and reliability by monitoring real-time vehicle data, enabling timely interventions only when deterioration or faults are detected. Both methods enhance vehicle performance, but condition-based inspection offers a more efficient allocation of resources and potentially reduces downtime.

Technology’s Role in Condition-based Inspection

Condition-based inspection leverages advanced sensor technology, IoT devices, and real-time data analytics to monitor asset health continuously, enabling predictive maintenance and reducing unexpected equipment failures. This approach contrasts with periodic inspection, which relies on scheduled checks regardless of actual asset condition, often leading to unnecessary downtime or overlooked issues. Integrating AI algorithms enhances the accuracy of condition assessments, optimizing maintenance schedules and extending equipment lifespan.

Choosing the Right Inspection Strategy

Choosing the right inspection strategy depends on factors such as equipment criticality, operational conditions, and failure modes. Periodic inspection offers a scheduled approach based on time or usage intervals, ensuring routine checks and maintenance, while condition-based inspection relies on real-time data and monitoring technologies to assess asset health and predict failures. Optimizing inspection strategy enhances reliability, reduces downtime, and lowers maintenance costs by aligning inspection frequency with actual equipment condition and risk.

Regulatory and Compliance Considerations

Periodic inspection mandates compliance with regulatory schedules and documented intervals, ensuring consistent adherence to safety standards and legal requirements. Condition-based inspection emphasizes real-time data monitoring and predictive maintenance, aligning with evolving compliance frameworks that accommodate flexible inspection frequencies based on equipment condition. Both approaches require thorough recordkeeping and timely reporting to regulatory bodies to maintain certification and avoid penalties.

Future Trends in Automotive Inspection Methods

Future trends in automotive inspection methods emphasize a shift from traditional periodic inspections to advanced condition-based inspection (CBI) systems that use real-time data and IoT sensors to monitor vehicle health continuously. Predictive analytics powered by AI algorithms enable early fault detection, reducing maintenance costs and enhancing safety by addressing issues before failures occur. The integration of machine learning and cloud-based platforms further facilitates remote diagnostics and adaptive inspection schedules tailored to individual vehicle usage patterns.

Periodic Inspection vs Condition-based Inspection Infographic

cardiffo.com

cardiffo.com