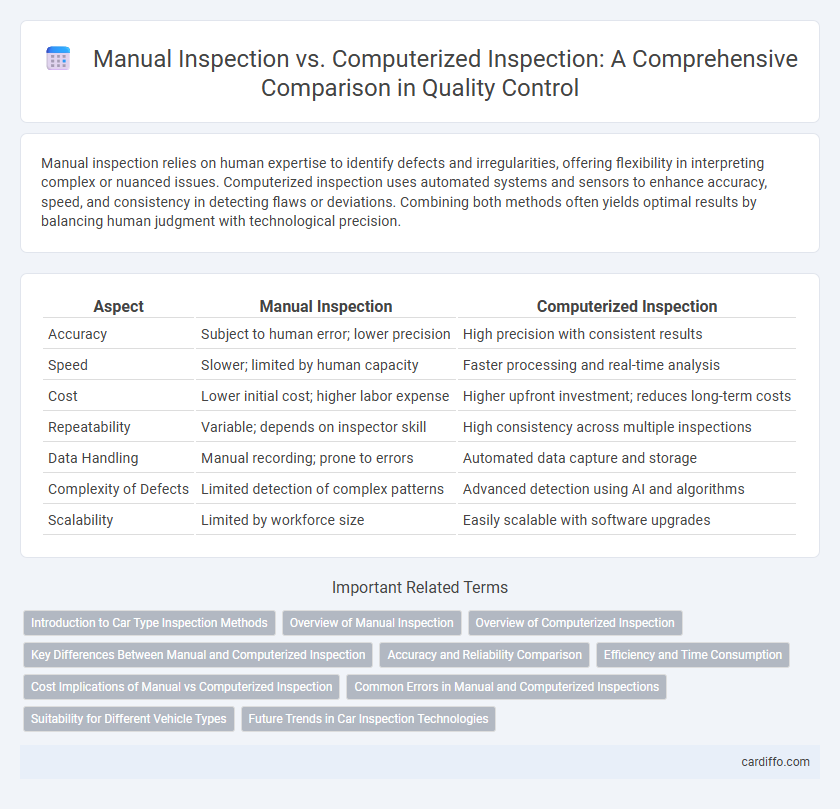

Manual inspection relies on human expertise to identify defects and irregularities, offering flexibility in interpreting complex or nuanced issues. Computerized inspection uses automated systems and sensors to enhance accuracy, speed, and consistency in detecting flaws or deviations. Combining both methods often yields optimal results by balancing human judgment with technological precision.

Table of Comparison

| Aspect | Manual Inspection | Computerized Inspection |

|---|---|---|

| Accuracy | Subject to human error; lower precision | High precision with consistent results |

| Speed | Slower; limited by human capacity | Faster processing and real-time analysis |

| Cost | Lower initial cost; higher labor expense | Higher upfront investment; reduces long-term costs |

| Repeatability | Variable; depends on inspector skill | High consistency across multiple inspections |

| Data Handling | Manual recording; prone to errors | Automated data capture and storage |

| Complexity of Defects | Limited detection of complex patterns | Advanced detection using AI and algorithms |

| Scalability | Limited by workforce size | Easily scalable with software upgrades |

Introduction to Car Type Inspection Methods

Manual inspection relies on human expertise to evaluate vehicle conditions, identifying defects based on visual and tactile assessment. Computerized inspection employs advanced sensors and software algorithms to analyze data, enabling precise detection of faults and real-time monitoring. Combining both methods enhances accuracy and efficiency in car type inspection processes.

Overview of Manual Inspection

Manual inspection involves human operators visually assessing products or components to detect defects, inconsistencies, or compliance issues. It relies heavily on the inspector's expertise, experience, and attention to detail for accurate quality control. Despite being time-consuming and subject to human error, manual inspection remains valuable in industries requiring nuanced judgments and flexibility.

Overview of Computerized Inspection

Computerized inspection leverages advanced imaging technologies, machine learning algorithms, and automated data analysis to enhance accuracy and efficiency in quality control processes. It enables rapid detection of defects, consistent evaluation, and real-time reporting, reducing human error and increasing throughput in manufacturing environments. Integration with industrial IoT and AI platforms allows continuous monitoring and predictive maintenance, optimizing overall operational performance.

Key Differences Between Manual and Computerized Inspection

Manual inspection relies on human sensory perception and judgment to identify defects or irregularities, often resulting in variability depending on the inspector's experience and fatigue. Computerized inspection utilizes advanced technologies such as machine vision, sensors, and artificial intelligence to provide consistent, high-speed, and precise defect detection with minimal human intervention. Key differences include accuracy, repeatability, scalability, and the integration of data analytics for real-time quality control and reporting.

Accuracy and Reliability Comparison

Computerized inspection consistently outperforms manual inspection in accuracy by minimizing human error and providing precise, repeatable measurements through advanced sensors and algorithms. Manual inspection, while flexible and adaptable to complex scenarios, often suffers from variability due to human fatigue and subjective judgment, leading to less reliable results. The integration of automated systems enhances reliability by maintaining consistent inspection criteria and generating comprehensive data logs for traceability and quality control.

Efficiency and Time Consumption

Manual inspection often requires significant time and human effort, leading to potential bottlenecks and variability in efficiency. Computerized inspection leverages automation and advanced algorithms to deliver faster, more consistent results, significantly reducing time consumption. The integration of computer vision and machine learning enhances defect detection accuracy, optimizing overall inspection workflows.

Cost Implications of Manual vs Computerized Inspection

Manual inspection generally incurs higher labor costs due to the extensive human involvement and longer inspection times compared to computerized inspection systems. Computerized inspection, while involving upfront investments in technology and software, reduces ongoing operational expenses through automation and increased inspection speed. Over time, computerized inspection tends to offer greater cost efficiency and scalability, especially for high-volume or complex inspection tasks.

Common Errors in Manual and Computerized Inspections

Common errors in manual inspection often include human fatigue, subjective judgment, and inconsistent measurements, leading to reduced accuracy and reliability. Computerized inspections may face errors due to sensor malfunctions, software bugs, and calibration issues, resulting in false positives or missed defects. Combining manual oversight with computerized systems enhances error detection by leveraging human intuition and automated precision.

Suitability for Different Vehicle Types

Manual inspection offers flexibility ideal for classic and custom vehicles where unique, intricate details demand human judgment, while computerized inspection excels with mass-produced, modern vehicles through automated precision and consistent data analysis. Computerized systems leverage advanced sensors, AI, and machine learning algorithms to efficiently detect issues in standardized vehicle models, optimizing accuracy and speed. Consequently, selection between manual and computerized inspection depends heavily on vehicle complexity and production scale, ensuring appropriate methods align with specific inspection needs.

Future Trends in Car Inspection Technologies

Future trends in car inspection technologies emphasize the integration of computerized inspection systems with advanced AI and machine learning algorithms, enabling higher accuracy and faster defect detection compared to traditional manual inspection methods. Computerized inspections leverage sensors, cameras, and real-time data analytics to provide comprehensive diagnostic insights, reducing human error and improving consistency. The ongoing development of autonomous inspection robots and IoT-connected smart devices is set to revolutionize vehicle maintenance by streamlining processes and enabling predictive maintenance models.

Manual inspection vs computerized inspection Infographic

cardiffo.com

cardiffo.com