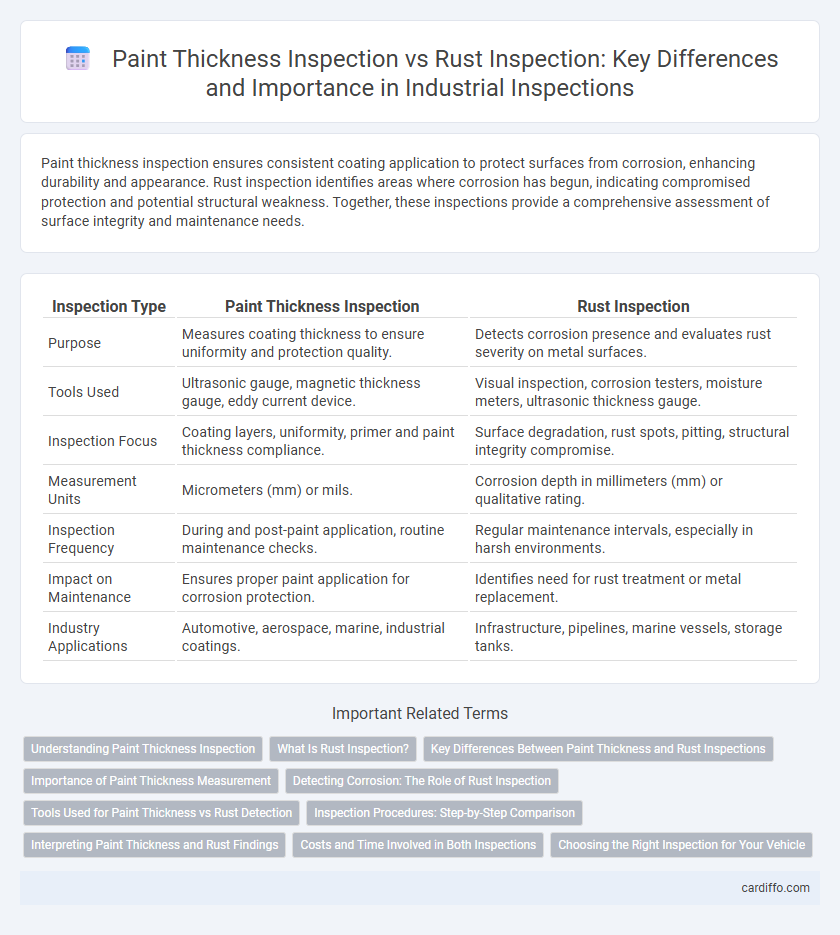

Paint thickness inspection ensures consistent coating application to protect surfaces from corrosion, enhancing durability and appearance. Rust inspection identifies areas where corrosion has begun, indicating compromised protection and potential structural weakness. Together, these inspections provide a comprehensive assessment of surface integrity and maintenance needs.

Table of Comparison

| Inspection Type | Paint Thickness Inspection | Rust Inspection |

|---|---|---|

| Purpose | Measures coating thickness to ensure uniformity and protection quality. | Detects corrosion presence and evaluates rust severity on metal surfaces. |

| Tools Used | Ultrasonic gauge, magnetic thickness gauge, eddy current device. | Visual inspection, corrosion testers, moisture meters, ultrasonic thickness gauge. |

| Inspection Focus | Coating layers, uniformity, primer and paint thickness compliance. | Surface degradation, rust spots, pitting, structural integrity compromise. |

| Measurement Units | Micrometers (mm) or mils. | Corrosion depth in millimeters (mm) or qualitative rating. |

| Inspection Frequency | During and post-paint application, routine maintenance checks. | Regular maintenance intervals, especially in harsh environments. |

| Impact on Maintenance | Ensures proper paint application for corrosion protection. | Identifies need for rust treatment or metal replacement. |

| Industry Applications | Automotive, aerospace, marine, industrial coatings. | Infrastructure, pipelines, marine vessels, storage tanks. |

Understanding Paint Thickness Inspection

Paint thickness inspection measures the coating's uniformity and ensures protection against corrosion, directly impacting the longevity of metal surfaces. This process uses tools like ultrasonic gauges to detect variations in paint layers, preventing premature rust formation by maintaining adequate coverage. Unlike rust inspection, which identifies existing corrosion damage, paint thickness inspection proactively assesses coating quality to avoid future rust development.

What Is Rust Inspection?

Rust inspection involves evaluating metal surfaces for corrosion, identifying early signs of rust formation that can compromise structural integrity. Techniques such as visual inspection, ultrasonic thickness measurement, and magnetic particle testing are commonly used to detect and assess rust severity. Unlike paint thickness inspection that measures coating layers to ensure protection, rust inspection focuses on damage assessment and preventive maintenance to extend asset lifespan.

Key Differences Between Paint Thickness and Rust Inspections

Paint thickness inspection measures the uniformity and adequacy of coating layers using tools like ultrasonic gauges, ensuring optimal protection against environmental factors. Rust inspection focuses on detecting and assessing corrosion presence on surfaces, often employing visual checks, magnetic methods, or advanced imaging to identify deterioration. Key differences lie in their objectives: paint thickness inspection evaluates protective coating integrity, while rust inspection identifies underlying metal degradation threats.

Importance of Paint Thickness Measurement

Paint thickness measurement is crucial for ensuring protective coatings effectively shield metal surfaces from corrosion and rust formation. Accurate paint thickness inspection helps maintain warranty compliance, prevents costly premature coating failures, and extends the lifespan of industrial assets. Rust inspection identifies existing corrosion, but paint thickness measurement proactively guarantees coating integrity before rust develops.

Detecting Corrosion: The Role of Rust Inspection

Rust inspection plays a critical role in detecting corrosion by identifying the early formation of rust beneath paint layers, which paint thickness inspection alone may not reveal. While paint thickness inspection measures coating uniformity and protection level, it cannot detect underlying corrosion that compromises structural integrity. Effective corrosion management requires combining rust inspection techniques like ultrasonic testing or visual inspection with paint thickness measurements for comprehensive damage assessment.

Tools Used for Paint Thickness vs Rust Detection

Paint thickness inspection typically utilizes ultrasonic thickness gauges and eddy current devices to provide precise, non-destructive measurements of coating layers. Rust inspection relies on visual inspection tools such as borescopes and advanced techniques including magnetic particle testing and corrosion sensors to identify underlying metal degradation. Both inspections employ specialized instruments tailored to detect either coating integrity or metal corrosion, ensuring comprehensive asset evaluation.

Inspection Procedures: Step-by-Step Comparison

Paint thickness inspection involves using magnetic or ultrasonic gauges to measure coating depth systematically across designated areas, ensuring uniformity and adherence to specifications. Rust inspection typically follows a visual and tactile examination combined with non-destructive testing methods such as ultrasonic thickness measurement and radiographic testing to detect corrosion beneath surfaces. Both inspections require documentation of findings, calibration of equipment, and adherence to safety and quality standards throughout the procedure.

Interpreting Paint Thickness and Rust Findings

Interpreting paint thickness involves measuring microns to assess coating uniformity and protection levels against corrosion, with deviations often indicating wear or previous repairs. Rust inspection focuses on identifying surface oxidation stages and underlying metal degradation to evaluate structural integrity and potential maintenance needs. Combining paint thickness data with rust findings provides a comprehensive understanding of coating performance and material condition, guiding effective preservation strategies.

Costs and Time Involved in Both Inspections

Paint thickness inspection typically requires specialized ultrasonic or magnetic gauges, offering rapid measurements with minimal surface preparation, resulting in lower labor costs and shorter inspection times compared to rust inspection. Rust inspection often involves visual assessments combined with techniques like ultrasonic thickness measurement or surface sampling, which can be more time-consuming and labor-intensive due to the need for corrosion identification and severity evaluation. Consequently, paint thickness inspection generally incurs lower overall costs and faster turnaround, while rust inspection demands higher investment in time and resources to ensure accurate corrosion detection and assessment.

Choosing the Right Inspection for Your Vehicle

Choosing the right inspection for your vehicle depends on evaluating paint thickness and rust presence to ensure optimal protection and longevity. Paint thickness inspection measures the coating's depth to identify inconsistencies or previous repairs, while rust inspection detects corrosion that can compromise structural integrity. Selecting between these inspections requires assessing your vehicle's history and exposure to elements to prevent costly damage and maintain its value.

Paint thickness inspection vs rust inspection Infographic

cardiffo.com

cardiffo.com