Frame inspection evaluates the structural integrity and dimensions of a frame to ensure it meets design specifications and safety standards. Alignment inspection focuses on the precise positioning and orientation of components relative to each other to guarantee optimal performance and reduce wear. Both inspections are critical in manufacturing and maintenance processes to prevent defects and prolong equipment lifespan.

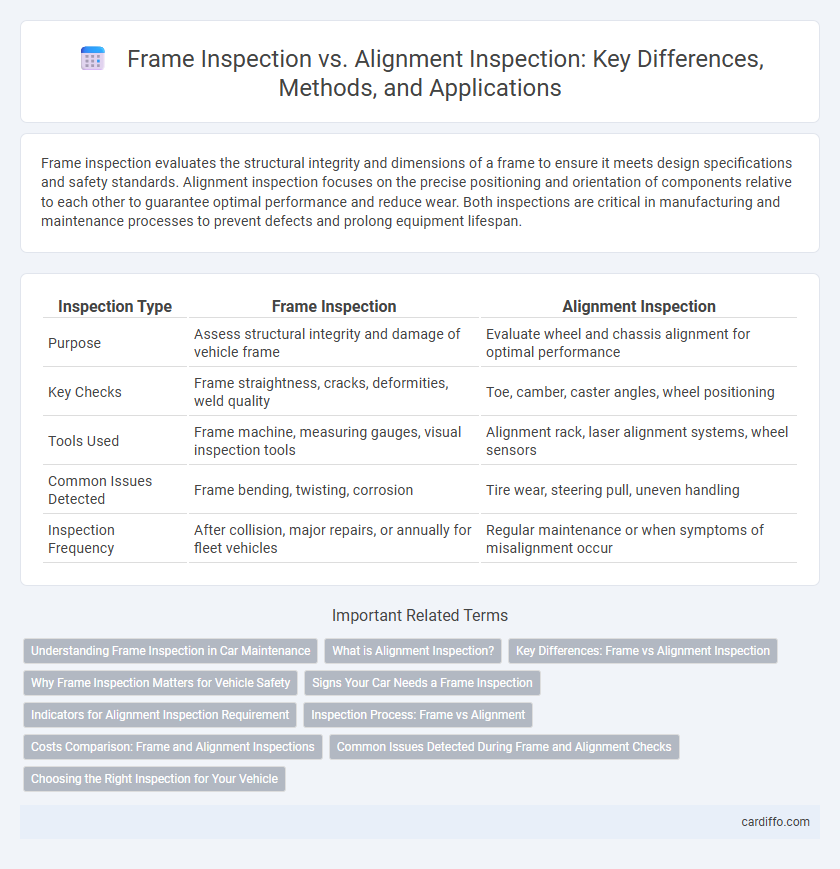

Table of Comparison

| Inspection Type | Frame Inspection | Alignment Inspection |

|---|---|---|

| Purpose | Assess structural integrity and damage of vehicle frame | Evaluate wheel and chassis alignment for optimal performance |

| Key Checks | Frame straightness, cracks, deformities, weld quality | Toe, camber, caster angles, wheel positioning |

| Tools Used | Frame machine, measuring gauges, visual inspection tools | Alignment rack, laser alignment systems, wheel sensors |

| Common Issues Detected | Frame bending, twisting, corrosion | Tire wear, steering pull, uneven handling |

| Inspection Frequency | After collision, major repairs, or annually for fleet vehicles | Regular maintenance or when symptoms of misalignment occur |

Understanding Frame Inspection in Car Maintenance

Frame inspection in car maintenance involves assessing the structural integrity of a vehicle's chassis to detect any bends, cracks, or warping caused by accidents or wear. This inspection uses precise measurement tools and often includes computerized scanning to ensure the frame aligns with manufacturer specifications, crucial for safety and vehicle performance. Unlike alignment inspection, which focuses on wheel positioning and steering angles, frame inspection addresses the foundational framework that supports the entire vehicle.

What is Alignment Inspection?

Alignment inspection evaluates the precise positioning and orientation of components within a structure to ensure they meet design specifications and functional requirements. It involves measuring angular relationships, distances, and parallelism to detect misalignments that could cause operational inefficiencies or safety hazards. This process is critical in industries such as automotive, aerospace, and construction, where accurate alignment affects performance and durability.

Key Differences: Frame vs Alignment Inspection

Frame inspection focuses on checking the physical condition, structural integrity, and dimensions of vehicle frames to ensure they meet safety and manufacturing standards. Alignment inspection assesses the angles and positioning of wheels relative to each other and the frame, ensuring optimal handling, tire wear, and vehicle stability. The key difference lies in frame inspection targeting the structural framework, while alignment inspection evaluates wheel geometry and its impact on vehicle performance.

Why Frame Inspection Matters for Vehicle Safety

Frame inspection is crucial for vehicle safety because it ensures the structural integrity of the chassis, which directly affects crashworthiness and handling. Detecting misalignments, cracks, or corrosion early prevents compromised frame components that could lead to accidents or failures during operation. Proper frame inspection supports accurate alignment inspections, ensuring optimal tire wear, steering response, and overall vehicle stability on the road.

Signs Your Car Needs a Frame Inspection

Visible bending or warping in the vehicle's structure, uneven tire wear, and difficulty steering are key signs your car needs a frame inspection. Misalignment of doors, trunk, or hood, along with unusual vibrations while driving, often indicate underlying frame damage requiring professional evaluation. Regular frame inspections help ensure vehicle safety, structural integrity, and proper alignment.

Indicators for Alignment Inspection Requirement

Frame inspection primarily evaluates structural integrity, whereas alignment inspection focuses on geometric precision and backlash indicators relevant for functional performance. Critical indicators for alignment inspection requirements include angular deviations, parallelism, concentricity, and gap measurements, ensuring components fit and operate within specified tolerances. These precision metrics help detect misalignments that could lead to premature wear or mechanical failure.

Inspection Process: Frame vs Alignment

Frame inspection involves evaluating the structural integrity and dimensions of a vehicle or equipment frame to detect distortions, cracks, or misalignments using tools like gauges, lasers, and visual assessments. Alignment inspection measures the angles and positioning of wheels or components relative to manufacturer specifications, ensuring optimal performance and wear patterns through tools such as wheel alignment machines and computerized imaging systems. Both inspections utilize precise measurement techniques but target different aspects: frame inspection addresses structural soundness, while alignment inspection focuses on functional geometry.

Costs Comparison: Frame and Alignment Inspections

Frame inspection typically involves a more comprehensive assessment using advanced equipment, resulting in higher labor and equipment costs compared to alignment inspection. Alignment inspection primarily focuses on wheel positioning and suspension angles, which requires less time and fewer resources, leading to lower overall expenses. Choosing between the two depends on the extent of damage and the specific diagnostic requirements, with frame inspections costing 30-50% more on average.

Common Issues Detected During Frame and Alignment Checks

Frame inspection commonly detects issues such as structural bends, cracks, and corrosion that compromise vehicle integrity, while alignment inspection primarily identifies problems like uneven tire wear, steering wheel misalignment, and improper camber or toe angles. Both inspections reveal underlying damage from collisions or suspension wear, with frame checks targeting the chassis and alignment checks focusing on wheel position relative to the frame. Regular frame and alignment inspections ensure vehicle safety, preventing handling difficulties and premature component deterioration.

Choosing the Right Inspection for Your Vehicle

Frame inspection evaluates the structural integrity of your vehicle's chassis to identify bends, cracks, or warping that can compromise safety and performance. Alignment inspection focuses on checking and adjusting the angles of the wheels to ensure proper tire wear, handling, and fuel efficiency. Choosing the right inspection depends on symptoms like uneven tire wear or vehicle pulling for alignment, while visible damage or accident history calls for a thorough frame inspection.

Frame Inspection vs Alignment Inspection Infographic

cardiffo.com

cardiffo.com