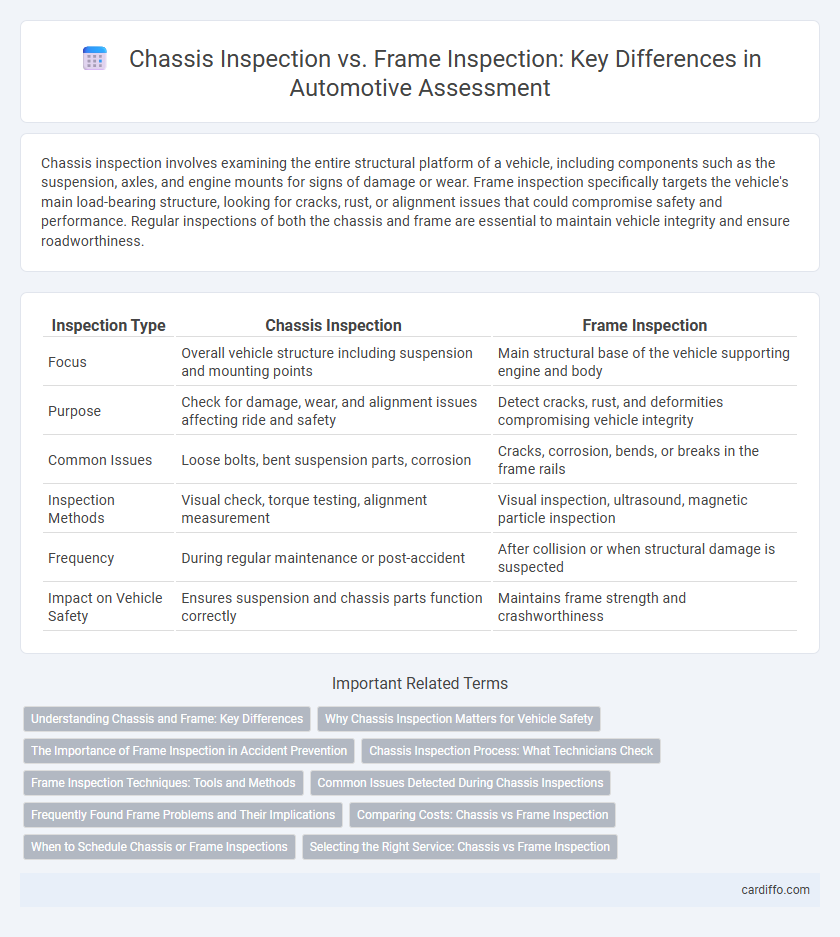

Chassis inspection involves examining the entire structural platform of a vehicle, including components such as the suspension, axles, and engine mounts for signs of damage or wear. Frame inspection specifically targets the vehicle's main load-bearing structure, looking for cracks, rust, or alignment issues that could compromise safety and performance. Regular inspections of both the chassis and frame are essential to maintain vehicle integrity and ensure roadworthiness.

Table of Comparison

| Inspection Type | Chassis Inspection | Frame Inspection |

|---|---|---|

| Focus | Overall vehicle structure including suspension and mounting points | Main structural base of the vehicle supporting engine and body |

| Purpose | Check for damage, wear, and alignment issues affecting ride and safety | Detect cracks, rust, and deformities compromising vehicle integrity |

| Common Issues | Loose bolts, bent suspension parts, corrosion | Cracks, corrosion, bends, or breaks in the frame rails |

| Inspection Methods | Visual check, torque testing, alignment measurement | Visual inspection, ultrasound, magnetic particle inspection |

| Frequency | During regular maintenance or post-accident | After collision or when structural damage is suspected |

| Impact on Vehicle Safety | Ensures suspension and chassis parts function correctly | Maintains frame strength and crashworthiness |

Understanding Chassis and Frame: Key Differences

Chassis inspection focuses on assessing the entire structural framework that supports the vehicle's body, engine, and other critical systems, ensuring overall integrity and alignment. Frame inspection specifically targets the underlying metal structure that forms the vehicle's base, checking for cracks, rust, or deformation that could compromise safety. Understanding these distinctions helps technicians perform precise evaluations to maintain vehicle stability and safety standards.

Why Chassis Inspection Matters for Vehicle Safety

Chassis inspection is critical for vehicle safety as it ensures the structural integrity and proper alignment of essential components like the suspension, steering system, and engine mounts. Unlike a frame inspection that primarily checks for cracks or damage to the vehicle's metal frame, chassis inspection evaluates the functionality of interconnected parts that affect handling, stability, and crash resilience. Detecting worn or damaged chassis elements early prevents mechanical failure and enhances overall road safety.

The Importance of Frame Inspection in Accident Prevention

Frame inspection is crucial in accident prevention as it identifies structural weaknesses that could compromise vehicle integrity during impact. Unlike chassis inspection, which examines the undercarriage and suspension, frame inspection specifically ensures the core structure has no cracks, bends, or corrosion that may lead to catastrophic failures. Regular frame assessments help maintain vehicle safety standards and prevent accidents resulting from hidden frame damage.

Chassis Inspection Process: What Technicians Check

Technicians performing a chassis inspection focus on key components such as suspension systems, steering mechanisms, brake lines, and structural integrity to ensure vehicle safety and performance. They look for signs of wear, corrosion, cracks, and alignment issues that could affect drivability and safety. Unlike a frame inspection, which primarily examines the vehicle's main structural frame, chassis inspections encompass a broader evaluation of all interconnected mechanical parts supporting the vehicle.

Frame Inspection Techniques: Tools and Methods

Frame inspection techniques utilize non-destructive testing (NDT) tools such as ultrasonic testers, magnetic particle inspection kits, and dye penetrant kits to detect cracks, corrosion, and structural weaknesses. Advanced methods include 3D laser scanning for dimensional accuracy and computerized tomography (CT) for internal defect analysis, enabling precise evaluation of frame integrity. Regular frame inspections employ visual checks combined with digital measurement tools to ensure alignment and compliance with safety standards.

Common Issues Detected During Chassis Inspections

Common issues detected during chassis inspections include corrosion, cracks, and misalignment, which can compromise the vehicle's structural integrity and safety. Frame inspections focus more specifically on detecting bends, fractures, and rust in the load-bearing components of the frame, often using ultrasonic or magnetic particle testing methods. Identifying these defects early prevents further damage, improves vehicle performance, and ensures compliance with safety regulations.

Frequently Found Frame Problems and Their Implications

Chassis inspection primarily targets the overall structural integrity and alignment of a vehicle, while frame inspection zeroes in on specific issues like rust, cracks, and corrosion that compromise the frame's strength. Frequently found frame problems include rust pitting, frame twisting, and weld failures, which can lead to reduced load-bearing capacity, safety hazards, and premature vehicle wear. Identifying these defects early during a frame inspection ensures vehicle durability and prevents costly repairs or catastrophic failure.

Comparing Costs: Chassis vs Frame Inspection

Chassis inspection typically involves lower costs due to its focus on components such as suspension, brakes, and steering systems, whereas frame inspection requires more specialized equipment and expertise to assess structural integrity, leading to higher expenses. Frame inspections often incur additional costs for detailed welding and corrosion analysis, critical for vehicle safety evaluations. Choosing between chassis and frame inspection depends on the vehicle's condition and the necessity for comprehensive structural assessment versus routine maintenance checks.

When to Schedule Chassis or Frame Inspections

Chassis inspections should be scheduled during routine vehicle maintenance or after any significant impact to ensure structural integrity and detect hidden damage. Frame inspections are critical when there is visible distortion, rust, or after accidents affecting the vehicle's foundational support system. Timely inspections prevent safety hazards and costly repairs by identifying issues early in the chassis or frame components.

Selecting the Right Service: Chassis vs Frame Inspection

Selecting the right service between chassis inspection and frame inspection depends on the specific components and structural elements being assessed; chassis inspection evaluates the overall assembly including suspension, steering, and drivetrain, while frame inspection focuses exclusively on the vehicle's main structural framework. Thorough chassis inspection identifies issues affecting vehicle stability and performance, whereas frame inspection detects cracks, corrosion, or alignment problems critical to structural integrity. Choosing the appropriate inspection service ensures safety compliance and prevents costly repairs by addressing the precise area of concern.

Chassis inspection vs frame inspection Infographic

cardiffo.com

cardiffo.com