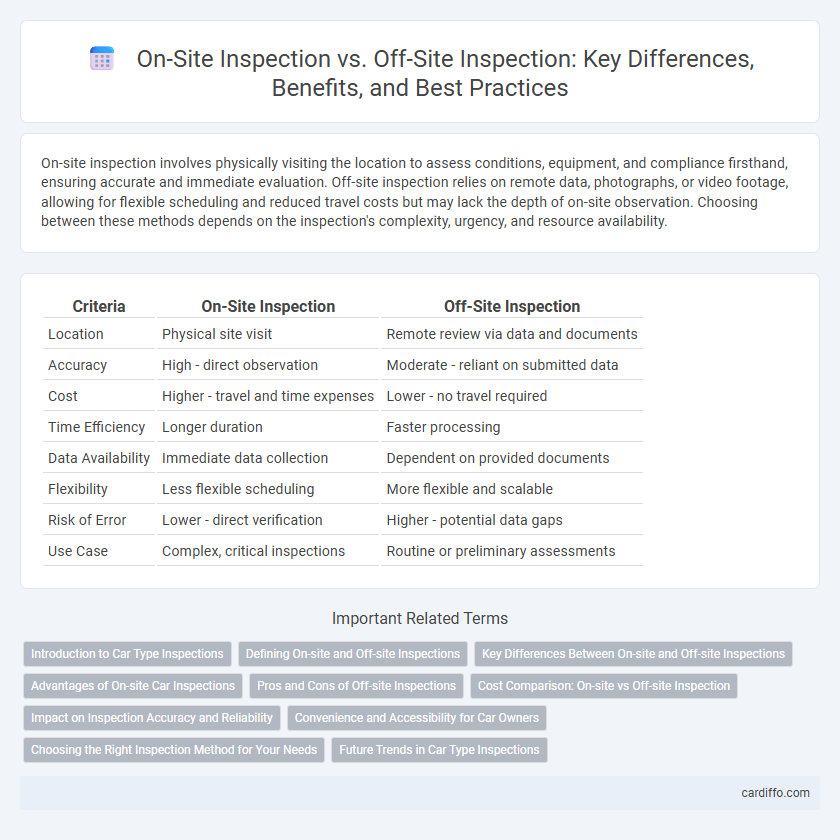

On-site inspection involves physically visiting the location to assess conditions, equipment, and compliance firsthand, ensuring accurate and immediate evaluation. Off-site inspection relies on remote data, photographs, or video footage, allowing for flexible scheduling and reduced travel costs but may lack the depth of on-site observation. Choosing between these methods depends on the inspection's complexity, urgency, and resource availability.

Table of Comparison

| Criteria | On-Site Inspection | Off-Site Inspection |

|---|---|---|

| Location | Physical site visit | Remote review via data and documents |

| Accuracy | High - direct observation | Moderate - reliant on submitted data |

| Cost | Higher - travel and time expenses | Lower - no travel required |

| Time Efficiency | Longer duration | Faster processing |

| Data Availability | Immediate data collection | Dependent on provided documents |

| Flexibility | Less flexible scheduling | More flexible and scalable |

| Risk of Error | Lower - direct verification | Higher - potential data gaps |

| Use Case | Complex, critical inspections | Routine or preliminary assessments |

Introduction to Car Type Inspections

On-site inspections involve physically examining vehicles at their current location, allowing inspectors to assess real-time conditions and identify issues such as damage, wear, and compliance with safety standards. Off-site inspections utilize remote data, photos, or vehicle history reports, offering convenience and efficiency but potentially missing nuanced physical details. Car type inspections vary based on these methods, with on-site inspections preferred for detailed quality checks and off-site inspections suited for initial assessments or large-scale fleet evaluations.

Defining On-site and Off-site Inspections

On-site inspection involves physical presence at the location of the asset, facility, or process being evaluated, enabling direct observation and immediate data collection. Off-site inspection refers to the remote evaluation of documents, reports, or digital data without physical presence, relying heavily on technology and communication tools. Both methods play critical roles in comprehensive inspection strategies, with on-site inspections offering tangible verification and off-site inspections providing efficiency and broader data analysis.

Key Differences Between On-site and Off-site Inspections

On-site inspections involve physically examining facilities, equipment, or operations at the location, allowing direct observation and immediate assessment of conditions and compliance. Off-site inspections rely on remote data review, documentation analysis, and digital communication, enabling flexibility and reduced travel costs but potentially limiting real-time observation. Key differences include the immediacy of feedback, the level of detail accessible, and the logistical requirements for inspectors and organizations.

Advantages of On-site Car Inspections

On-site car inspections provide real-time evaluation, allowing inspectors to assess the vehicle's condition in its actual environment, leading to more accurate and reliable results. These inspections enable immediate identification of potential issues, such as hidden damages or operational problems, that might be overlooked in off-site settings. Access to the vehicle's usage history and maintenance records on-site further enhances the thoroughness and precision of the inspection process.

Pros and Cons of Off-site Inspections

Off-site inspections offer increased flexibility and reduced costs by eliminating travel time and minimizing disruptions to regular operations. However, they may lack the thoroughness and contextual awareness of on-site inspections, potentially leading to missed issues that require physical observation. Reliance on digital data and remote communication can also introduce challenges related to data accuracy and real-time verification.

Cost Comparison: On-site vs Off-site Inspection

On-site inspections typically incur higher costs due to travel expenses, accommodation, and the need for specialized equipment at the location, making them less economical for frequent or widespread assessments. Off-site inspections leverage remote technologies such as video conferencing and data analysis, significantly reducing operational expenses and allowing for scalability without the burden of physical presence. Businesses must weigh these cost differences against the complexity and criticality of the inspection to determine the most cost-effective approach.

Impact on Inspection Accuracy and Reliability

On-site inspection allows direct examination of physical conditions, leading to higher accuracy and real-time verification of compliance, reducing errors caused by miscommunication or incomplete data. Off-site inspection relies heavily on pre-submitted documents, images, or data, which may limit the ability to detect subtle defects or discrepancies, potentially lowering reliability. The choice between on-site and off-site inspection significantly influences the thoroughness and validity of inspection outcomes, with on-site generally providing more precise and trustworthy results.

Convenience and Accessibility for Car Owners

On-site inspections provide car owners with unmatched convenience by allowing assessments at their preferred location, eliminating the need for travel and time off work. Off-site inspections, while requiring visits to dedicated facilities, often offer extended hours and specialized equipment that can enhance inspection accuracy. For car owners prioritizing ease and minimal disruption, on-site inspections are typically more accessible and user-friendly.

Choosing the Right Inspection Method for Your Needs

Choosing the right inspection method depends on factors such as the complexity of the asset, accessibility, and regulatory requirements. On-site inspection allows for direct observation and immediate problem identification, ideal for intricate machinery or environments requiring real-time data collection. Off-site inspection leverages remote technologies and data analysis, offering cost-efficiency and flexibility for preliminary assessments or when physical access is restricted.

Future Trends in Car Type Inspections

Future trends in car type inspections emphasize the integration of advanced technologies such as AI-powered image recognition and IoT-enabled sensors to enhance both on-site and off-site inspection accuracy. On-site inspections will increasingly incorporate mobile diagnostic tools and augmented reality to provide real-time data and detailed vehicle status to inspectors. Off-site inspections are expected to leverage cloud-based platforms and remote telemetry, enabling comprehensive vehicle assessments without the need for physical presence, thereby streamlining workflows and reducing inspection times.

On-site inspection vs off-site inspection Infographic

cardiffo.com

cardiffo.com