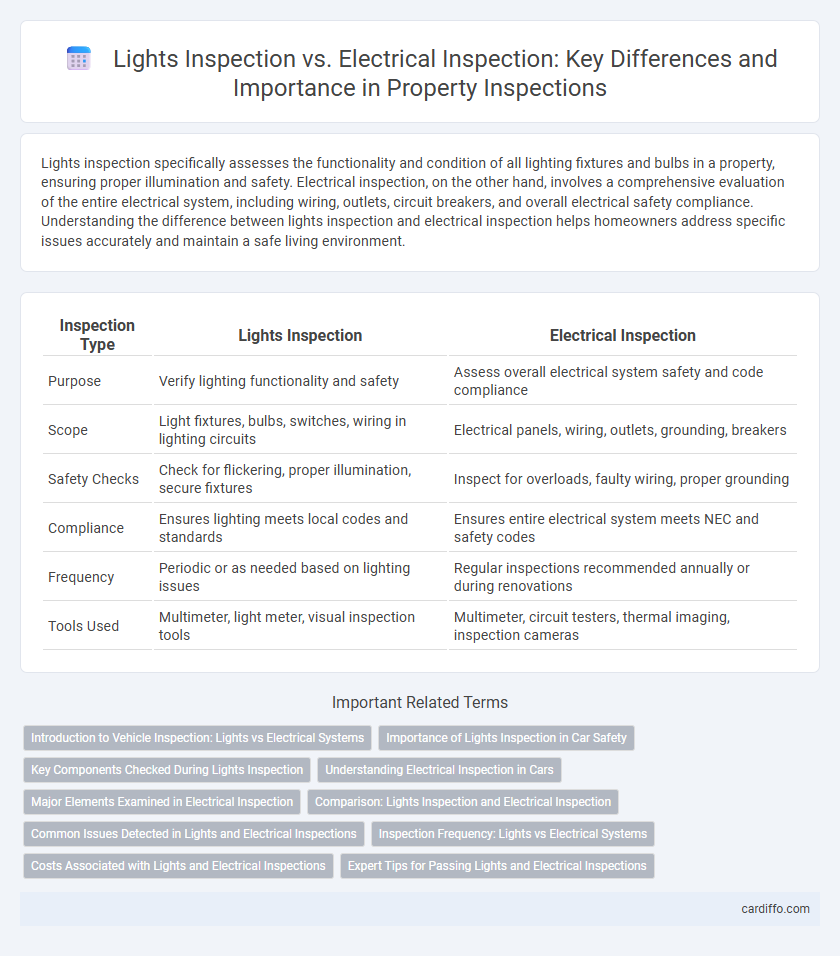

Lights inspection specifically assesses the functionality and condition of all lighting fixtures and bulbs in a property, ensuring proper illumination and safety. Electrical inspection, on the other hand, involves a comprehensive evaluation of the entire electrical system, including wiring, outlets, circuit breakers, and overall electrical safety compliance. Understanding the difference between lights inspection and electrical inspection helps homeowners address specific issues accurately and maintain a safe living environment.

Table of Comparison

| Inspection Type | Lights Inspection | Electrical Inspection |

|---|---|---|

| Purpose | Verify lighting functionality and safety | Assess overall electrical system safety and code compliance |

| Scope | Light fixtures, bulbs, switches, wiring in lighting circuits | Electrical panels, wiring, outlets, grounding, breakers |

| Safety Checks | Check for flickering, proper illumination, secure fixtures | Inspect for overloads, faulty wiring, proper grounding |

| Compliance | Ensures lighting meets local codes and standards | Ensures entire electrical system meets NEC and safety codes |

| Frequency | Periodic or as needed based on lighting issues | Regular inspections recommended annually or during renovations |

| Tools Used | Multimeter, light meter, visual inspection tools | Multimeter, circuit testers, thermal imaging, inspection cameras |

Introduction to Vehicle Inspection: Lights vs Electrical Systems

Vehicle inspection rigorously evaluates lights and electrical systems to ensure safety and functionality. Lights inspection focuses on headlamps, brake lights, turn signals, and hazard lights, verifying brightness, alignment, and operation for road compliance. Electrical inspection encompasses the battery, alternator, wiring, and fuses, detecting faults that could impair vehicle performance or pose safety risks.

Importance of Lights Inspection in Car Safety

Lights inspection plays a crucial role in car safety by ensuring all vehicle lighting systems function correctly, including headlights, brake lights, and turn signals. Properly working lights improve visibility during night driving and adverse weather conditions, reducing the risk of accidents. Regular lights inspection detects burnt-out bulbs and faulty wiring, preventing dangerous situations caused by impaired signaling to other drivers.

Key Components Checked During Lights Inspection

Lights inspection primarily targets key components such as bulbs, fixtures, wiring connections, sockets, and switches to ensure proper illumination and safety. Inspectors assess the integrity of light fittings, verify the functionality of timers or dimmers, and check for signs of wear or damage that could cause malfunction or hazards. This focus contrasts with electrical inspections, which broadly evaluate circuit breakers, outlets, wiring systems, and load capacities throughout the entire electrical infrastructure.

Understanding Electrical Inspection in Cars

Electrical inspection in cars involves a comprehensive evaluation of the vehicle's wiring, battery, alternator, and electronic control units to ensure safe and efficient operation. Unlike lights inspection, which primarily checks the functionality and visibility of headlights, taillights, and signal indicators, electrical inspection covers the entire electrical system, identifying issues like faulty connections, short circuits, and battery health. Understanding electrical inspection helps prevent breakdowns, maintain vehicle performance, and comply with safety regulations.

Major Elements Examined in Electrical Inspection

Electrical inspections primarily focus on major elements such as wiring integrity, circuit breakers, grounding systems, and load capacity to ensure safety and code compliance. In contrast, lights inspection emphasizes fixture condition, bulb functionality, and proper illumination levels without delving into the underlying electrical infrastructure. Accurate evaluation of circuit continuity, insulation resistance, and panel connections is critical to preventing hazards in electrical inspections.

Comparison: Lights Inspection and Electrical Inspection

Lights inspection primarily assesses the functionality, brightness, and positioning of lighting fixtures, ensuring compliance with safety and illumination standards. Electrical inspection encompasses a broader evaluation of wiring, circuit breakers, outlets, and overall electrical system integrity to prevent hazards such as short circuits or overloads. While lights inspection targets illumination quality, electrical inspection emphasizes system safety and code adherence across all electrical components.

Common Issues Detected in Lights and Electrical Inspections

Common issues detected during lights inspection include flickering bulbs, faulty wiring, and inadequate illumination levels that compromise safety and functionality. Electrical inspections often reveal overloaded circuits, faulty breakers, and poor grounding, which pose significant risks of electrical fires and equipment failures. Both inspections are critical for identifying hazards that affect energy efficiency, occupant safety, and code compliance.

Inspection Frequency: Lights vs Electrical Systems

Inspection frequency for lights typically occurs every 6 to 12 months to ensure proper functioning and safety compliance, while electrical system inspections are usually conducted every 1 to 3 years due to their complexity and critical impact on overall building safety. Light inspections focus on verifying bulb integrity, fixture condition, and illumination levels, whereas electrical inspections assess wiring, circuit breakers, grounding, and load capacity. Maintaining a regular inspection schedule for both lighting and electrical systems minimizes risks of electrical faults, fire hazards, and costly repairs.

Costs Associated with Lights and Electrical Inspections

Lights inspection costs typically range from $50 to $150 depending on the number of fixtures and complexity, while electrical inspections can cost between $100 and $300 due to the broader scope involving wiring, panels, and system safety. Lights inspections often require less time and specialized equipment, resulting in lower labor expenses compared to electrical inspections that demand certified electricians and detailed analysis. Budgeting for electrical inspections should account for potential repairs or upgrades identified during the process, which can significantly increase overall costs beyond the initial inspection fee.

Expert Tips for Passing Lights and Electrical Inspections

Expert tips for passing lights and electrical inspections include ensuring all light fixtures meet local code requirements for wattage, placement, and type, and verifying that wiring connections are secure and free from corrosion. Inspectors often prioritize functional testing, so consistently testing switches, outlets, and lighting controls before the inspection is crucial. Additionally, maintaining updated permits and documentation proves compliance and streamlines the approval process for both lighting and electrical systems.

Lights inspection vs electrical inspection Infographic

cardiffo.com

cardiffo.com