Thermal imaging inspection detects heat patterns and anomalies without physical contact, ensuring a non-invasive and efficient evaluation of pets' skin and underlying tissues. Touch inspection relies on physical examination to identify temperature changes or abnormalities but can miss subtle thermal variations critical for early diagnosis. Integrating thermal imaging enhances accuracy and allows veterinarians to identify issues invisible to the touch.

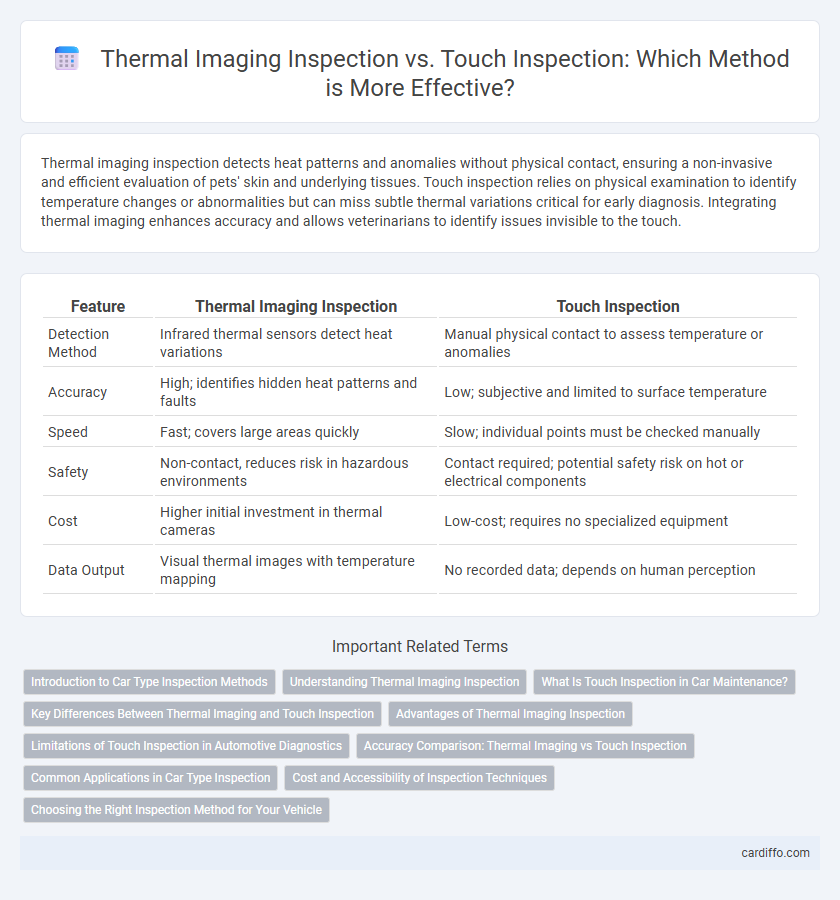

Table of Comparison

| Feature | Thermal Imaging Inspection | Touch Inspection |

|---|---|---|

| Detection Method | Infrared thermal sensors detect heat variations | Manual physical contact to assess temperature or anomalies |

| Accuracy | High; identifies hidden heat patterns and faults | Low; subjective and limited to surface temperature |

| Speed | Fast; covers large areas quickly | Slow; individual points must be checked manually |

| Safety | Non-contact, reduces risk in hazardous environments | Contact required; potential safety risk on hot or electrical components |

| Cost | Higher initial investment in thermal cameras | Low-cost; requires no specialized equipment |

| Data Output | Visual thermal images with temperature mapping | No recorded data; depends on human perception |

Introduction to Car Type Inspection Methods

Thermal imaging inspection offers a non-contact, precise method to detect heat anomalies in vehicles, identifying issues such as electrical faults or overheating components that may not be visible through traditional touch inspection. Touch inspection relies on physical contact to feel temperature differences, which can be less accurate and slower, especially in hard-to-reach areas or under complex engine layouts. Incorporating thermal imaging enhances the thoroughness and safety of car type inspection methods by providing real-time thermal data without risking technician exposure to hot surfaces.

Understanding Thermal Imaging Inspection

Thermal imaging inspection utilizes infrared cameras to detect temperature variations across surfaces, enabling the identification of hidden issues such as electrical faults, insulation defects, and moisture intrusion without physical contact. This non-invasive method provides real-time, precise thermal maps that reveal hot spots and irregular heat patterns invisible to the naked eye, enhancing early fault detection and preventive maintenance. Compared to touch inspection, thermal imaging offers faster, safer, and more comprehensive diagnostics, minimizing human error and eliminating the need to physically access potentially hazardous or hard-to-reach equipment.

What Is Touch Inspection in Car Maintenance?

Touch inspection in car maintenance involves physically feeling components to detect irregularities such as overheating, vibration, or wear. This method helps identify issues like hot spots on engine parts, loose bolts, or faulty hoses by sensing temperature differences and mechanical anomalies. While effective for immediate surface-level problems, touch inspection is often complemented by thermal imaging for more precise and comprehensive diagnostics.

Key Differences Between Thermal Imaging and Touch Inspection

Thermal imaging inspection detects temperature variations using infrared technology, enabling non-contact, real-time analysis of heat patterns in electrical systems, mechanical equipment, and building envelopes. Touch inspection relies on physical contact to identify issues such as overheating or structural weaknesses, often limited by human perception and accessibility. Thermal imaging offers enhanced safety, efficiency, and accuracy by revealing hidden faults invisible to the naked hand, while touch inspection provides direct tactile feedback but lacks comprehensive coverage.

Advantages of Thermal Imaging Inspection

Thermal imaging inspection offers the advantage of non-contact temperature measurement, enabling the detection of anomalies such as overheating or heat loss without physical interaction. It provides rapid, comprehensive coverage of large areas, increasing efficiency and safety by identifying issues in inaccessible or hazardous locations. Unlike touch inspection, thermal imaging captures precise temperature variations to prevent equipment failure and reduce maintenance costs through predictive diagnostics.

Limitations of Touch Inspection in Automotive Diagnostics

Touch inspection in automotive diagnostics is limited by its inability to detect subsurface or internal component issues that thermal imaging can reveal through temperature variations. Sensory evaluation depends heavily on human perception, making it prone to error and inconsistency, especially in detecting subtle or early-stage faults. Thermal imaging provides precise, non-contact analysis of heat patterns, offering a more accurate and comprehensive diagnostic tool compared to traditional touch inspection methods.

Accuracy Comparison: Thermal Imaging vs Touch Inspection

Thermal imaging inspection provides higher accuracy than touch inspection by detecting temperature variations and hidden faults without direct contact, enabling early identification of electrical or mechanical anomalies. Unlike touch inspection, which relies on subjective tactile feedback and can miss subsurface issues, thermal imaging captures precise thermal patterns for comprehensive analysis. This non-invasive technique reduces human error and enhances reliability in preventive maintenance and safety assessments.

Common Applications in Car Type Inspection

Thermal imaging inspection excels in identifying electrical faults, overheating components, and insulation failures in vehicles without physical contact, making it ideal for early detection of engine and battery issues. Touch inspection remains useful for detecting surface anomalies, fluid leaks, and mechanical wear through direct palpation, especially in brake systems and suspension components. Combining thermal imaging with touch inspection provides a comprehensive approach to diagnosing car malfunctions efficiently and accurately.

Cost and Accessibility of Inspection Techniques

Thermal imaging inspection offers a cost-effective solution by reducing labor time and enabling rapid detection of issues without physical contact, which lowers overall operational expenses compared to traditional touch inspections. Touch inspection often requires skilled personnel and extended downtime, leading to higher labor and maintenance costs. Accessibility advantages of thermal imaging include the ability to inspect hard-to-reach or hazardous areas safely, making it a more versatile and efficient choice for diverse inspection needs.

Choosing the Right Inspection Method for Your Vehicle

Thermal imaging inspection offers precise detection of hidden heat anomalies such as electrical faults and engine overheating, which are often missed by touch inspection. Touch inspection relies on human sensory perception, making it less effective for identifying internal or early-stage issues that lack visible or tactile symptoms. Choosing thermal imaging enhances diagnostic accuracy, reduces inspection time, and improves preventive maintenance for your vehicle.

Thermal imaging inspection vs touch inspection Infographic

cardiffo.com

cardiffo.com