NOx traps and SCR systems both target nitrogen oxide reduction but differ in mechanism and efficiency. NOx traps capture and store NOx molecules during lean combustion, releasing them during rich phases for reduction, while SCR systems use ammonia or urea to convert NOx into nitrogen and water over a catalyst. SCR systems generally achieve higher NOx reduction efficiency under a wider range of operating conditions, making them preferred for heavy-duty and commercial vehicles.

Table of Comparison

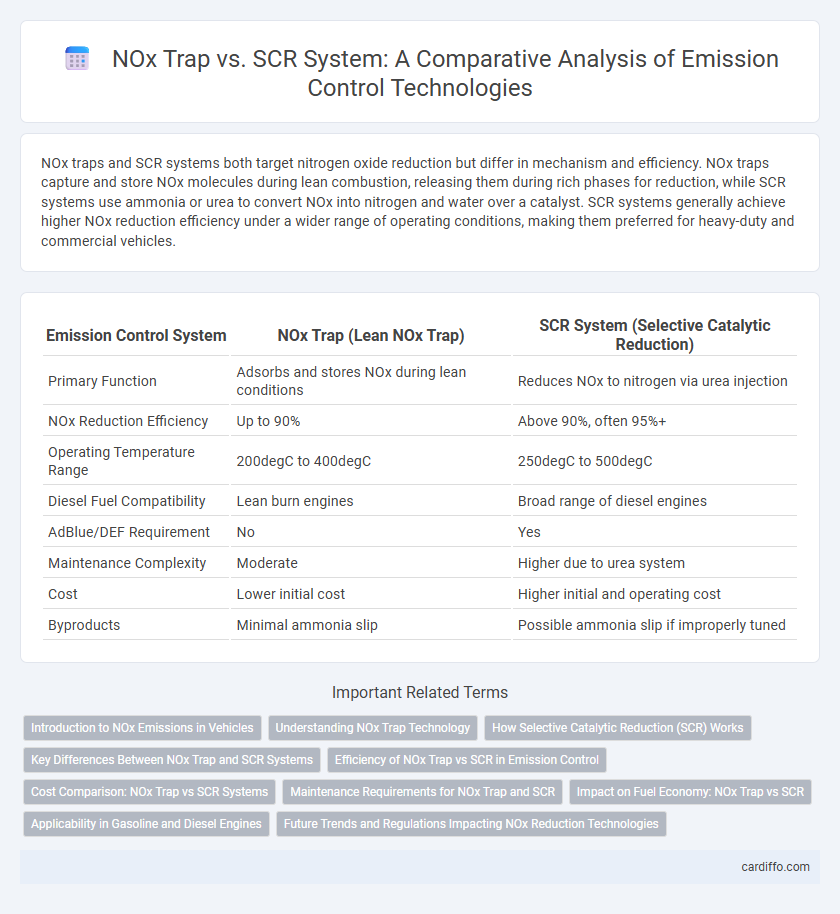

| Emission Control System | NOx Trap (Lean NOx Trap) | SCR System (Selective Catalytic Reduction) |

|---|---|---|

| Primary Function | Adsorbs and stores NOx during lean conditions | Reduces NOx to nitrogen via urea injection |

| NOx Reduction Efficiency | Up to 90% | Above 90%, often 95%+ |

| Operating Temperature Range | 200degC to 400degC | 250degC to 500degC |

| Diesel Fuel Compatibility | Lean burn engines | Broad range of diesel engines |

| AdBlue/DEF Requirement | No | Yes |

| Maintenance Complexity | Moderate | Higher due to urea system |

| Cost | Lower initial cost | Higher initial and operating cost |

| Byproducts | Minimal ammonia slip | Possible ammonia slip if improperly tuned |

Introduction to NOx Emissions in Vehicles

NOx emissions in vehicles primarily consist of nitrogen oxides produced during fuel combustion at high temperatures, contributing to air pollution and health hazards. NOx traps, also known as Lean NOx Traps (LNT), capture and store nitrogen oxides under lean conditions and reduce them during rich operation cycles. Selective Catalytic Reduction (SCR) systems inject a urea-based solution to chemically convert NOx into nitrogen and water, offering higher NOx reduction efficiency, especially in diesel engines.

Understanding NOx Trap Technology

NOx trap technology captures nitrogen oxides by adsorbing them onto a sorbent material during lean engine operation and reducing them to harmless nitrogen during brief rich combustion phases. This passive system excels in diesel engines by temporarily storing NOx emissions, preventing their release into the atmosphere. Compared to selective catalytic reduction (SCR) systems, NOx traps require less urea consumption but may face challenges with durability and efficiency under varying engine conditions.

How Selective Catalytic Reduction (SCR) Works

Selective Catalytic Reduction (SCR) reduces nitrogen oxides (NOx) emissions by injecting a urea-based reductant into the exhaust stream, which reacts with NOx over a catalyst to form harmless nitrogen and water. This process operates efficiently at high temperatures typical of diesel engine exhaust, enabling significant NOx reduction up to 90%. SCR systems outperform NOx trap systems in longevity and effectiveness under variable engine loads and speeds.

Key Differences Between NOx Trap and SCR Systems

NOx traps, also known as Lean NOx Traps (LNT), capture and store nitrogen oxides during lean engine operation and periodically regenerate by reducing the stored NOx to nitrogen, whereas Selective Catalytic Reduction (SCR) systems use a urea-based reductant to convert NOx into nitrogen and water continuously. NOx traps are generally more compact and suited for smaller engines but have a limited NOx storage capacity, while SCR systems offer higher NOx reduction efficiency, especially under varying load conditions, and are favored for heavy-duty applications. SCR systems require a separate reductant supply and maintenance, unlike NOx traps that integrate storage and reduction in a single catalyst.

Efficiency of NOx Trap vs SCR in Emission Control

NOx traps, also known as Lean NOx Traps (LNT), effectively reduce nitrogen oxides by adsorbing NOx during lean engine operation and periodically regenerating under rich conditions, achieving up to 70-90% NOx conversion efficiency. Selective Catalytic Reduction (SCR) systems utilize ammonia or urea injection combined with a catalyst to convert NOx into nitrogen and water, often reaching over 90% NOx conversion efficiency, especially in heavy-duty diesel applications. SCR systems generally outperform NOx traps in long-term efficiency and durability, particularly under varying engine loads and temperatures, making SCR the preferred technology for stringent emission regulations.

Cost Comparison: NOx Trap vs SCR Systems

NOx trap systems typically involve lower initial costs compared to SCR systems due to simpler catalyst design and reduced complexity in engine integration. However, SCR systems offer better long-term cost efficiency through higher NOx reduction performance, lower fuel penalties, and longer catalyst lifespan. Maintenance expenses tend to be higher for NOx traps because of frequent regeneration cycles, while SCR systems benefit from optimized urea consumption and less frequent component replacement.

Maintenance Requirements for NOx Trap and SCR

NOx trap systems demand periodic regeneration cycles to remove trapped nitrogen oxides, requiring careful temperature control and catalyst monitoring to prevent degradation. SCR systems rely on regular replenishment of urea-based reducing agents and frequent inspection of the catalyst for ammonia slip and fouling. Maintenance protocols for NOx traps are generally more intensive due to thermal aging, while SCR systems focus on fluid management and sensor calibration for optimal performance.

Impact on Fuel Economy: NOx Trap vs SCR

NOx Trap technology typically increases fuel consumption due to periodic rich regeneration cycles that burn additional fuel to remove trapped nitrogen oxides. In contrast, Selective Catalytic Reduction (SCR) systems maintain better fuel economy by using a urea-based reductant to convert NOx into nitrogen and water under lean conditions without the need for rich combustion. Consequently, SCR systems offer a more efficient balance between NOx reduction and fuel economy in heavy-duty diesel engines.

Applicability in Gasoline and Diesel Engines

NOx Trap technology, also known as Lean NOx Trap (LNT), is primarily effective for lean-burn gasoline engines by adsorbing and periodically reducing nitrogen oxides during rich combustion cycles. Selective Catalytic Reduction (SCR) systems are widely applicable in diesel engines, using a urea-based reductant to convert NOx into nitrogen and water, achieving higher NOx reduction efficiency under varying load conditions. SCR systems excel in heavy-duty diesel vehicles due to their robustness and adaptability, while NOx Traps suit light-duty gasoline engines with lean operation strategies.

Future Trends and Regulations Impacting NOx Reduction Technologies

Emerging regulations targeting stricter NOx emission limits are accelerating the adoption of advanced selective catalytic reduction (SCR) systems due to their higher efficiency in reducing nitrogen oxides compared to NOx traps. Future trends emphasize integration of SCR with onboard diagnostics and real-time monitoring to ensure compliance with Euro 7 and EPA Tier 4 standards. Innovations in catalyst materials and hybrid systems are anticipated to enhance durability and cost-effectiveness amid tightening global emissions mandates.

NOx Trap vs SCR System Infographic

cardiffo.com

cardiffo.com