Catalytic converters reduce harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides by converting them into less toxic emissions through chemical reactions. Diesel Particulate Filters (DPF) specifically target and trap particulate matter, such as soot and ash, from diesel exhaust to prevent it from entering the atmosphere. Both technologies are essential in modern vehicles for minimizing pollution but serve distinct roles in controlling gaseous pollutants versus solid particulates.

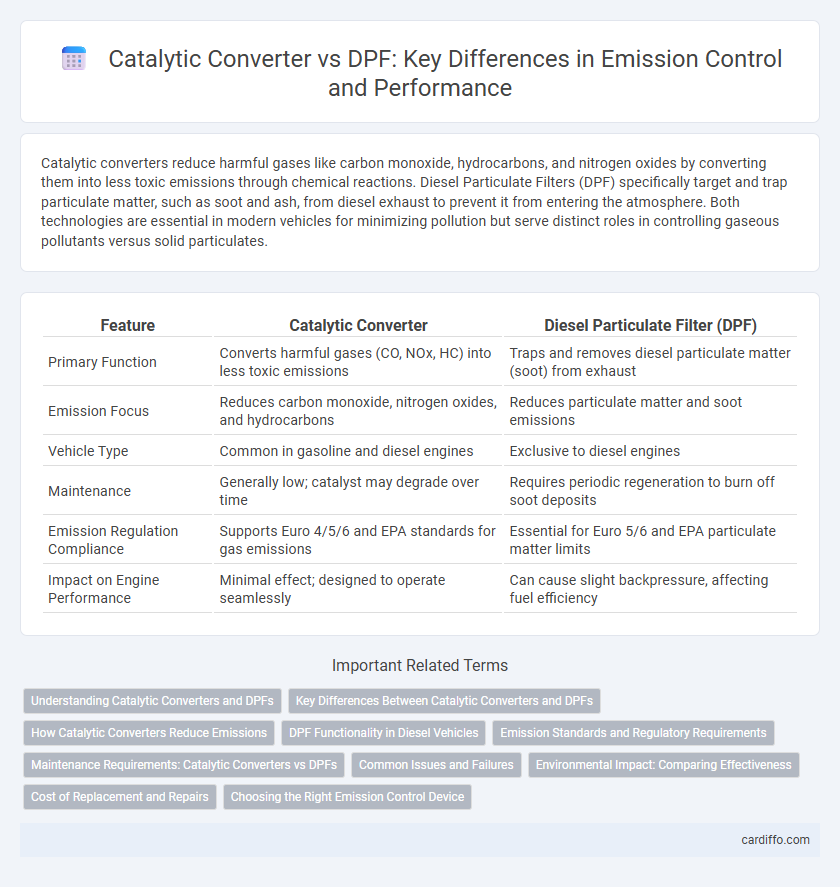

Table of Comparison

| Feature | Catalytic Converter | Diesel Particulate Filter (DPF) |

|---|---|---|

| Primary Function | Converts harmful gases (CO, NOx, HC) into less toxic emissions | Traps and removes diesel particulate matter (soot) from exhaust |

| Emission Focus | Reduces carbon monoxide, nitrogen oxides, and hydrocarbons | Reduces particulate matter and soot emissions |

| Vehicle Type | Common in gasoline and diesel engines | Exclusive to diesel engines |

| Maintenance | Generally low; catalyst may degrade over time | Requires periodic regeneration to burn off soot deposits |

| Emission Regulation Compliance | Supports Euro 4/5/6 and EPA standards for gas emissions | Essential for Euro 5/6 and EPA particulate matter limits |

| Impact on Engine Performance | Minimal effect; designed to operate seamlessly | Can cause slight backpressure, affecting fuel efficiency |

Understanding Catalytic Converters and DPFs

Catalytic converters reduce harmful emissions by converting carbon monoxide, hydrocarbons, and nitrogen oxides into less toxic gases using catalysts like platinum, palladium, and rhodium. Diesel Particulate Filters (DPFs) specifically target particulate matter by trapping soot from diesel exhaust before it is released into the atmosphere. Understanding the distinct roles of catalytic converters and DPFs helps optimize emission control technologies for both gasoline and diesel engines.

Key Differences Between Catalytic Converters and DPFs

Catalytic converters reduce harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides by converting them into less toxic substances through chemical reactions, while Diesel Particulate Filters (DPFs) capture and store soot and particulate matter from diesel exhaust to prevent their release. Catalytic converters primarily target gaseous emissions in both gasoline and diesel engines, whereas DPFs are specifically designed for diesel engines to address particulate pollution. Maintenance for catalytic converters involves ensuring catalyst efficiency, but DPFs require regular regeneration to burn off accumulated soot and prevent clogging.

How Catalytic Converters Reduce Emissions

Catalytic converters reduce emissions by converting harmful gases like carbon monoxide (CO), nitrogen oxides (NOx), and hydrocarbons (HC) into less toxic substances such as carbon dioxide (CO2), nitrogen (N2), and water vapor through chemical reactions facilitated by catalysts like platinum, palladium, and rhodium. These devices play a crucial role in controlling exhaust pollutants from gasoline engines, significantly lowering smog-forming compounds and improving air quality. Unlike Diesel Particulate Filters (DPF) that primarily trap soot particles, catalytic converters target gaseous emissions, enhancing overall vehicle emission performance.

DPF Functionality in Diesel Vehicles

A Diesel Particulate Filter (DPF) captures and stores soot particles from diesel engine exhaust, preventing harmful emissions from entering the atmosphere. It operates by trapping particulate matter and periodically undergoing a regeneration process that burns off the accumulated soot at high temperatures. DPF technology significantly reduces particulate emissions, enhancing air quality and helping diesel vehicles comply with stringent environmental regulations.

Emission Standards and Regulatory Requirements

Catalytic converters primarily target carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) to meet Euro 6 and EPA Tier 3 emission standards, while Diesel Particulate Filters (DPF) focus on capturing particulate matter (PM) to comply with Euro 6d and California CARB regulations. Regulatory requirements mandate periodic monitoring of catalytic converter efficiency and DPF regeneration to ensure sustained emission reduction performance. Both systems are integral to reducing vehicular emissions and achieving compliance with stringent global environmental policies.

Maintenance Requirements: Catalytic Converters vs DPFs

Catalytic converters require periodic inspection to ensure the catalyst materials remain effective, with maintenance typically involving oxygen sensor checks and occasional replacement after 70,000 to 100,000 miles. Diesel Particulate Filters (DPFs) demand more frequent and intensive maintenance, including regular regeneration cycles to burn off soot and prevent clogging, along with potential manual cleaning or replacement every 100,000 to 120,000 miles. Proper upkeep of both devices is essential to maintain emission reduction efficiency and comply with environmental regulations.

Common Issues and Failures

Catalytic converters often face issues like clogging, catalyst poisoning, and thermal degradation, leading to reduced efficiency and increased emissions. Diesel Particulate Filters (DPFs) commonly suffer from soot accumulation and regeneration failure, causing blockages and engine performance problems. Both systems require proper maintenance and timely diagnostics to prevent costly repairs and ensure compliance with emission standards.

Environmental Impact: Comparing Effectiveness

Catalytic converters reduce harmful gases like carbon monoxide and nitrogen oxides by converting them into less toxic substances, significantly lowering air pollution. Diesel Particulate Filters (DPFs) target particulate matter by trapping soot emissions, effectively decreasing the presence of fine particles responsible for respiratory issues. Both technologies contribute to emission control, but catalytic converters mainly address gaseous pollutants while DPFs specialize in particulate reduction, making their environmental impacts complementary in combating different pollutants.

Cost of Replacement and Repairs

Catalytic converters generally have a lower replacement cost, typically ranging from $1,000 to $2,500, compared to Diesel Particulate Filters (DPF), which can exceed $3,000 due to their complex design. Repairing a catalytic converter is often less expensive and more straightforward, while DPF repairs or replacements involve advanced sensors and regeneration technology, driving up labor costs. Insurance and emissions test failures can further impact the overall expense associated with both components.

Choosing the Right Emission Control Device

Choosing the right emission control device depends on the type of pollutants targeted and vehicle application; catalytic converters primarily reduce carbon monoxide, hydrocarbons, and nitrogen oxides through chemical reactions, while diesel particulate filters (DPF) capture and oxidize particulate matter from diesel exhaust. Vehicles with gasoline engines typically utilize catalytic converters, whereas diesel engines require DPFs to meet stringent particulate emission standards. Effectively combining these technologies in modern vehicles ensures compliance with regulations like Euro 6 and EPA Tier 3, optimizing air quality and engine performance.

Catalytic Converter vs DPF Infographic

cardiffo.com

cardiffo.com