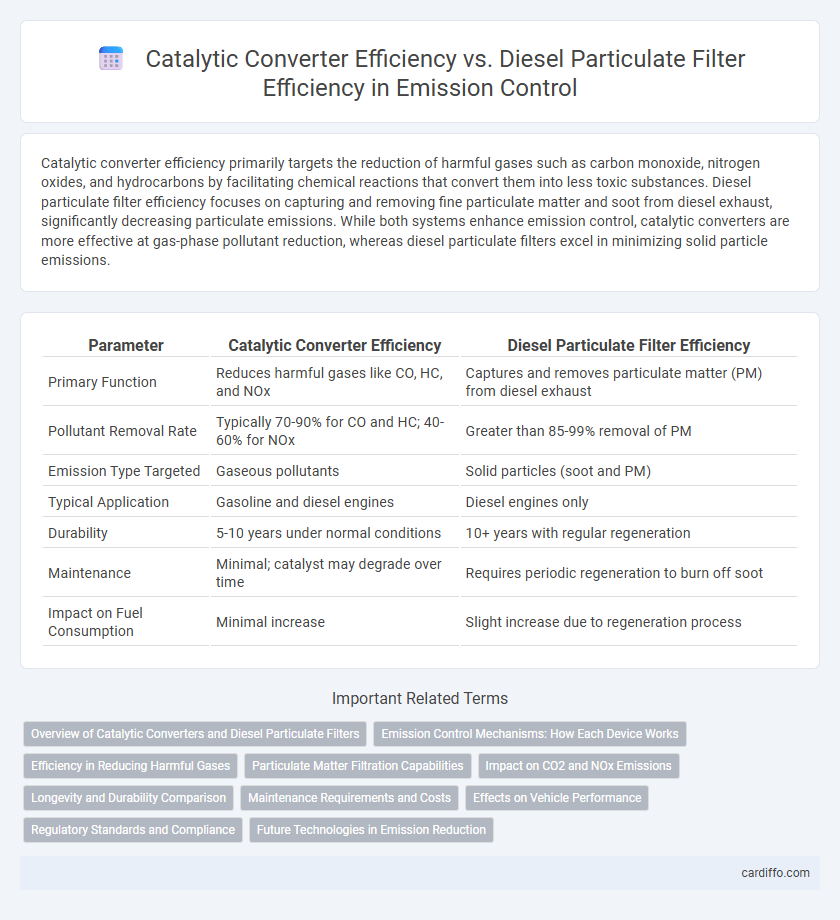

Catalytic converter efficiency primarily targets the reduction of harmful gases such as carbon monoxide, nitrogen oxides, and hydrocarbons by facilitating chemical reactions that convert them into less toxic substances. Diesel particulate filter efficiency focuses on capturing and removing fine particulate matter and soot from diesel exhaust, significantly decreasing particulate emissions. While both systems enhance emission control, catalytic converters are more effective at gas-phase pollutant reduction, whereas diesel particulate filters excel in minimizing solid particle emissions.

Table of Comparison

| Parameter | Catalytic Converter Efficiency | Diesel Particulate Filter Efficiency |

|---|---|---|

| Primary Function | Reduces harmful gases like CO, HC, and NOx | Captures and removes particulate matter (PM) from diesel exhaust |

| Pollutant Removal Rate | Typically 70-90% for CO and HC; 40-60% for NOx | Greater than 85-99% removal of PM |

| Emission Type Targeted | Gaseous pollutants | Solid particles (soot and PM) |

| Typical Application | Gasoline and diesel engines | Diesel engines only |

| Durability | 5-10 years under normal conditions | 10+ years with regular regeneration |

| Maintenance | Minimal; catalyst may degrade over time | Requires periodic regeneration to burn off soot |

| Impact on Fuel Consumption | Minimal increase | Slight increase due to regeneration process |

Overview of Catalytic Converters and Diesel Particulate Filters

Catalytic converters reduce harmful emissions by converting carbon monoxide, hydrocarbons, and nitrogen oxides into less toxic gases through oxidation and reduction reactions. Diesel particulate filters (DPFs) trap and oxidize particulate matter from diesel exhaust, significantly lowering black soot emissions and improving air quality. Both technologies are critical for meeting stringent emission standards, with catalytic converters targeting gaseous pollutants and DPFs specializing in particulate removal.

Emission Control Mechanisms: How Each Device Works

Catalytic converters reduce emissions by converting harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides into less toxic substances through oxidation and reduction reactions facilitated by precious metal catalysts like platinum, palladium, and rhodium. Diesel particulate filters (DPFs) capture and store particulate matter (PM) from diesel exhaust, periodically regenerating to burn off the accumulated soot at high temperatures, significantly lowering particulate emissions. Both devices are critical in emission control systems, with catalytic converters targeting gaseous pollutants and DPFs focusing on particulate reduction for comprehensive exhaust cleaning.

Efficiency in Reducing Harmful Gases

Catalytic converters achieve approximately 90% efficiency in reducing harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides by facilitating chemical reactions that convert these pollutants into less harmful substances. Diesel particulate filters, while primarily targeting particulate matter with a reduction efficiency of up to 85-95%, also contribute indirectly to lowering overall emission toxicity by capturing soot and fine particles. Combining these technologies in diesel engines significantly enhances emission reduction, optimizing air quality by addressing both gaseous pollutants and particulate emissions.

Particulate Matter Filtration Capabilities

Catalytic converters primarily reduce harmful gases like carbon monoxide and nitrogen oxides but have limited effectiveness in filtering particulate matter (PM) from diesel exhaust. Diesel particulate filters (DPFs) excel in capturing fine particulate matter, including soot and ultrafine particles, achieving filtration efficiencies greater than 85-95%. The superior PM filtration capabilities of DPFs make them essential for controlling diesel emissions and meeting stringent particulate matter regulatory standards.

Impact on CO2 and NOx Emissions

Catalytic converters primarily reduce harmful NOx emissions by converting nitrogen oxides into nitrogen and oxygen, significantly improving air quality without directly impacting CO2 levels. Diesel particulate filters (DPFs) effectively trap soot and particulate matter from diesel exhaust, indirectly lowering CO2 emissions by enabling more efficient combustion and regeneration cycles. Combining catalytic converters with DPFs provides a comprehensive emission control strategy, achieving substantial reductions in both NOx and particulate emissions while maintaining optimized fuel efficiency.

Longevity and Durability Comparison

Catalytic converters typically exhibit high efficiency in reducing carbon monoxide and hydrocarbons, maintaining functionality for 70,000 to 100,000 miles before significant degradation occurs, whereas diesel particulate filters (DPFs) focus on trapping soot and particulate matter with efficiency that can exceed 90% but require regular regeneration to prevent clogging. Longevity of catalytic converters depends on catalyst poison resistance and thermal stability, often lasting over 8 years, while DPFs may face durability challenges due to repeated thermal cycles during regeneration, potentially necessitating replacement within 5 to 8 years. Proper maintenance and fuel quality are critical factors influencing the durability and sustained performance of both emission control devices.

Maintenance Requirements and Costs

Catalytic converters require less frequent maintenance than diesel particulate filters (DPFs) due to their simpler design and fewer moving parts, resulting in lower overall operational costs. DPFs need regular cleaning or replacement to prevent clogging from soot accumulation, which increases maintenance complexity and expenses significantly. The higher maintenance demands of DPFs contribute to increased downtime and service costs compared to the relatively low-maintenance catalytic converters.

Effects on Vehicle Performance

Catalytic converter efficiency significantly reduces harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides, enhancing engine performance by promoting cleaner combustion and optimizing fuel efficiency. Diesel particulate filters excel at capturing soot and fine particulate matter, which minimizes engine wear and maintains turbocharger integrity but can increase backpressure, potentially reducing engine power output. Balancing the efficiencies of both systems is crucial to optimizing vehicle emission standards while preserving overall performance and fuel economy.

Regulatory Standards and Compliance

Catalytic converters typically achieve up to 90% reduction in harmful gases like CO, NOx, and hydrocarbons, meeting stringent Euro 6 and EPA Tier 3 emission standards. Diesel particulate filters (DPFs) focus on capturing over 85% of particulate matter (PM) emissions, crucial for compliance with particulate limits set by Euro VI and CARB regulations. Vehicles equipped with both systems ensure comprehensive emission control, aligning with evolving global regulatory frameworks targeting both gaseous pollutants and particulate matter to reduce environmental impact.

Future Technologies in Emission Reduction

Future emission reduction technologies emphasize enhancing catalytic converter efficiency through advanced catalyst materials that accelerate oxidation reactions, while diesel particulate filters (DPFs) focus on improved filtration media to capture ultrafine particles with higher precision. Innovations such as nano-structured catalysts and self-regenerating DPF designs significantly reduce NOx and particulate matter emissions in diesel engines. Combining these advancements with real-time monitoring systems enables optimized emission control, pushing diesel engines closer to zero-emission standards.

Catalytic Converter Efficiency vs Diesel Particulate Filter Efficiency Infographic

cardiffo.com

cardiffo.com