Catalytic converters effectively reduce harmful gases like carbon monoxide, nitrogen oxides, and hydrocarbons by facilitating redox reactions, while Diesel Particulate Filters (DPFs) primarily capture and oxidize particulate matter such as soot. Catalytic converters excel in treating gaseous emissions from both gasoline and diesel engines, whereas DPFs are specifically designed for diesel engines to mitigate particulate pollution. Combining both technologies provides comprehensive emission control, optimizing overall air quality by addressing both gaseous pollutants and solid particulates.

Table of Comparison

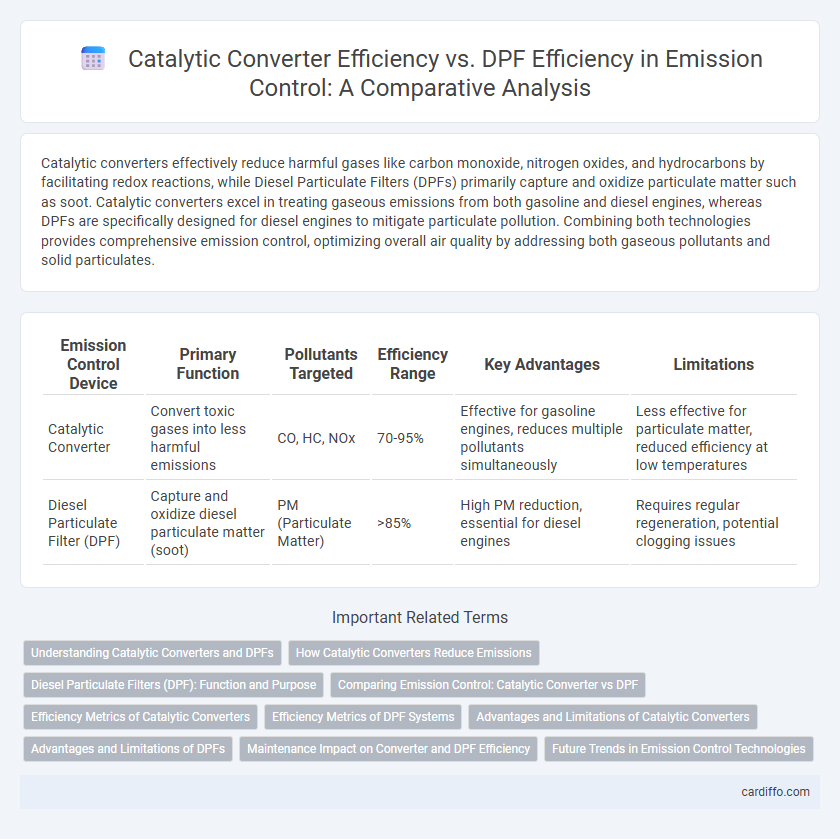

| Emission Control Device | Primary Function | Pollutants Targeted | Efficiency Range | Key Advantages | Limitations |

|---|---|---|---|---|---|

| Catalytic Converter | Convert toxic gases into less harmful emissions | CO, HC, NOx | 70-95% | Effective for gasoline engines, reduces multiple pollutants simultaneously | Less effective for particulate matter, reduced efficiency at low temperatures |

| Diesel Particulate Filter (DPF) | Capture and oxidize diesel particulate matter (soot) | PM (Particulate Matter) | >85% | High PM reduction, essential for diesel engines | Requires regular regeneration, potential clogging issues |

Understanding Catalytic Converters and DPFs

Catalytic converters effectively reduce harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides by facilitating chemical reactions that convert them into less toxic substances. Diesel Particulate Filters (DPFs) specifically target particulate matter emissions, trapping soot and requiring periodic regeneration to maintain efficiency. Understanding the complementary functions of catalytic converters and DPFs is crucial for optimizing overall vehicle emission control systems.

How Catalytic Converters Reduce Emissions

Catalytic converters reduce emissions by converting harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides into less toxic substances such as carbon dioxide, nitrogen, and water through redox reactions facilitated by platinum, palladium, and rhodium catalysts. Their efficiency depends on factors like operating temperature, catalyst surface area, and exhaust flow rate, typically achieving conversion rates between 70-90% for targeted pollutants. Unlike diesel particulate filters (DPFs) that primarily capture soot and particulate matter, catalytic converters focus on chemical transformation of gaseous pollutants, essential for reducing smog-forming emissions and improving air quality.

Diesel Particulate Filters (DPF): Function and Purpose

Diesel Particulate Filters (DPFs) are designed to trap and remove soot particles from diesel engine exhaust, significantly reducing particulate matter emissions and helping meet stringent environmental regulations. Unlike catalytic converters that primarily reduce gaseous pollutants such as carbon monoxide, hydrocarbons, and nitrogen oxides, DPFs specifically target solid particle emissions, enhancing overall emission control in diesel vehicles. Efficient regeneration processes in DPFs ensure continuous filtration performance, preventing clogging and maintaining engine efficiency while minimizing harmful particulate release.

Comparing Emission Control: Catalytic Converter vs DPF

Catalytic converters efficiently reduce harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides through chemical reactions, achieving conversion rates of up to 90%. Diesel Particulate Filters (DPF) primarily target particulate matter, capturing up to 85-95% of soot and ash emissions from diesel engines to improve air quality. While catalytic converters excel at gas-phase pollutant reduction, DPFs are essential for controlling solid particulate emissions, making both technologies complementary in comprehensive vehicle emission control.

Efficiency Metrics of Catalytic Converters

Catalytic converters achieve high efficiency by converting over 90% of harmful gases such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less toxic emissions like carbon dioxide (CO2) and nitrogen (N2). Efficiency metrics for catalytic converters primarily measure conversion rates, typically exceeding 90% under optimal operating conditions, which significantly reduces urban air pollution compared to diesel particulate filters (DPFs) that focus mainly on particulate matter (PM) reduction. While DPFs excel in trapping particulate emissions, catalytic converter efficiency is crucial for controlling gas-phase pollutants, making their performance central to overall vehicle emission control strategies.

Efficiency Metrics of DPF Systems

Diesel Particulate Filters (DPFs) demonstrate high efficiency in removing particulate matter, typically capturing over 85-95% of soot emissions, outperforming catalytic converters in particulate reduction. Efficiency metrics for DPF systems focus on parameters like filtration efficiency, backpressure impact, and regeneration effectiveness, which directly influence emission compliance and fuel economy. Unlike catalytic converters that primarily target gaseous pollutants, DPFs provide a critical function in reducing fine particulate emissions, essential for meeting stringent diesel emission standards.

Advantages and Limitations of Catalytic Converters

Catalytic converters efficiently reduce harmful gases like carbon monoxide, hydrocarbons, and nitrogen oxides by converting them into less toxic substances through chemical reactions. Their main advantage lies in rapid pollutant conversion at relatively low temperatures, making them ideal for gasoline engines, but they have limitations in capturing particulate matter compared to diesel particulate filters (DPFs). Catalytic converters also degrade over time due to catalyst poisoning and thermal damage, reducing long-term efficiency in emission control.

Advantages and Limitations of DPFs

Diesel Particulate Filters (DPFs) excel at trapping and reducing particulate matter (PM) emissions by capturing soot particles effectively, improving air quality and meeting stringent environmental regulations. However, DPFs require periodic regeneration to burn off accumulated soot, which can increase fuel consumption and impose maintenance challenges; their efficiency can also be compromised by poor engine calibration or low-temperature operation. Compared to catalytic converters, which primarily target gaseous pollutants like CO and NOx, DPFs uniquely address particulate emissions but depend heavily on optimal operating conditions for sustained performance.

Maintenance Impact on Converter and DPF Efficiency

Catalytic converter efficiency relies heavily on regular maintenance to prevent clogging and poisoning from contaminants, which can drastically reduce its ability to catalyze harmful emissions. Diesel Particulate Filters (DPFs) require periodic regeneration and cleaning to maintain optimal soot trapping efficiency, as accumulated particles can cause backpressure and reduced filtration performance. Neglecting maintenance accelerates degradation in both systems, leading to increased emissions and potential failure of emission control compliance.

Future Trends in Emission Control Technologies

Catalytic converter efficiency is evolving with advanced catalyst materials that enhance NOx, CO, and hydrocarbon conversion at lower temperatures, while Diesel Particulate Filters (DPFs) are improving soot capture and regeneration processes to reduce particulate matter emissions. Future trends include integrating selective catalytic reduction (SCR) with DPF systems to optimize overall emission control, leveraging nanotechnology for increased catalyst surface area and durability. Emission regulations are driving innovations towards hybrid systems combining catalytic converters and DPFs, aiming to meet stricter global standards for both gaseous pollutants and particulate emissions.

Catalytic converter efficiency vs DPF efficiency Infographic

cardiffo.com

cardiffo.com