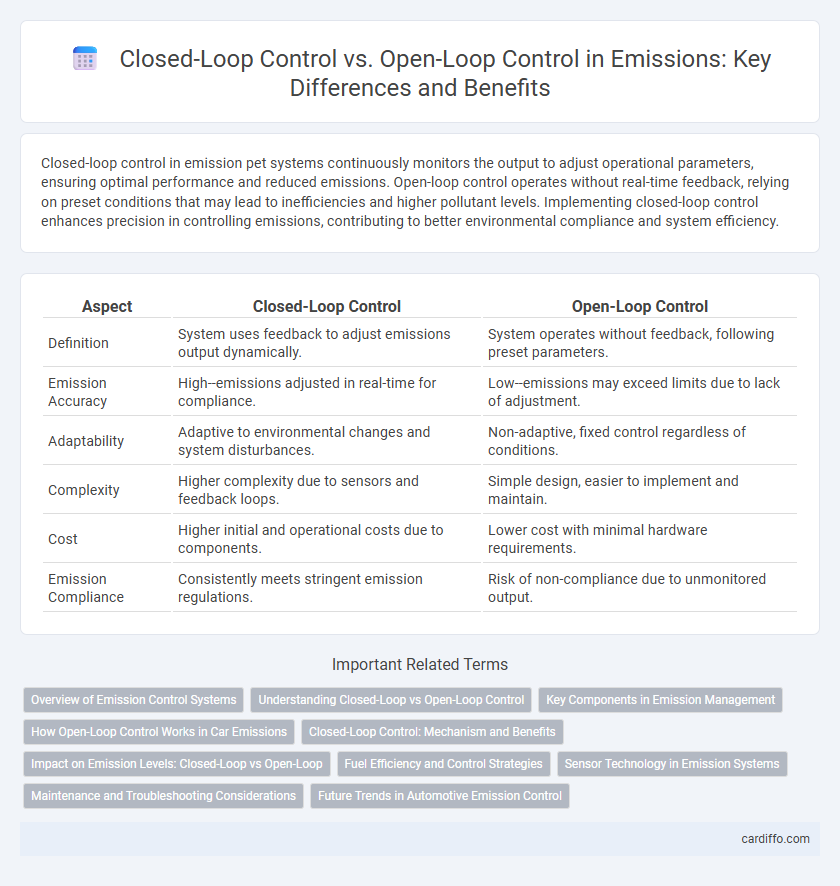

Closed-loop control in emission pet systems continuously monitors the output to adjust operational parameters, ensuring optimal performance and reduced emissions. Open-loop control operates without real-time feedback, relying on preset conditions that may lead to inefficiencies and higher pollutant levels. Implementing closed-loop control enhances precision in controlling emissions, contributing to better environmental compliance and system efficiency.

Table of Comparison

| Aspect | Closed-Loop Control | Open-Loop Control |

|---|---|---|

| Definition | System uses feedback to adjust emissions output dynamically. | System operates without feedback, following preset parameters. |

| Emission Accuracy | High--emissions adjusted in real-time for compliance. | Low--emissions may exceed limits due to lack of adjustment. |

| Adaptability | Adaptive to environmental changes and system disturbances. | Non-adaptive, fixed control regardless of conditions. |

| Complexity | Higher complexity due to sensors and feedback loops. | Simple design, easier to implement and maintain. |

| Cost | Higher initial and operational costs due to components. | Lower cost with minimal hardware requirements. |

| Emission Compliance | Consistently meets stringent emission regulations. | Risk of non-compliance due to unmonitored output. |

Overview of Emission Control Systems

Closed-loop emission control systems utilize real-time feedback from sensors to continuously adjust engine parameters, reducing pollutants like CO, NOx, and hydrocarbons more precisely than open-loop systems. Open-loop control relies on preset conditions without sensor feedback, often leading to less accurate emission reductions under varying operating conditions. Modern vehicles predominantly use closed-loop systems to meet stringent emission standards established by regulatory bodies such as the EPA and Euro 6.

Understanding Closed-Loop vs Open-Loop Control

Closed-loop control systems continuously monitor emissions through feedback sensors to adjust parameters in real-time, ensuring optimal pollutant reduction. Open-loop control operates without feedback, relying on predefined settings that may not adapt effectively to changing emission conditions. Understanding these mechanisms is crucial for optimizing emission control strategies in industrial and automotive applications.

Key Components in Emission Management

Closed-loop control systems in emission management utilize sensors, controllers, and actuators to continuously monitor and adjust emissions in real-time, ensuring optimal performance and compliance with regulatory standards. In contrast, open-loop control relies on preset parameters without feedback, limiting its responsiveness to changing emission levels and environmental conditions. Key components such as oxygen sensors, electronic control units (ECUs), and catalytic converters are critical in closed-loop systems for precise emission reduction and efficient engine operation.

How Open-Loop Control Works in Car Emissions

Open-loop control in car emissions operates by sending predetermined signals from the engine control unit (ECU) to fuel injectors and ignition systems without feedback from emission sensors, relying on fixed calibration values. This system controls the air-fuel mixture and combustion timing based on expected engine conditions, which can lead to higher emissions under variable driving scenarios. Unlike closed-loop control, open-loop systems do not adjust in real-time to oxygen sensor data, resulting in less precise regulation of pollutants such as NOx, CO, and unburned hydrocarbons.

Closed-Loop Control: Mechanism and Benefits

Closed-loop control systems continuously monitor emissions through sensors and adjust operational parameters in real time to maintain optimal environmental compliance. This feedback mechanism enhances accuracy in reducing pollutants by dynamically responding to fluctuations in emission levels. As a result, closed-loop control significantly improves efficiency and reliability compared to open-loop systems, minimizing both regulatory risks and environmental impact.

Impact on Emission Levels: Closed-Loop vs Open-Loop

Closed-loop control systems continuously monitor and adjust engine parameters based on real-time emission feedback, significantly reducing pollutants such as NOx and CO compared to open-loop systems that operate on fixed inputs without emission feedback. Open-loop control often leads to higher emission levels due to lack of adaptation to changing engine conditions and environmental factors. Implementing closed-loop control enhances compliance with stringent emission regulations and improves overall air quality by maintaining optimal combustion efficiency.

Fuel Efficiency and Control Strategies

Closed-loop control systems optimize fuel efficiency by continuously monitoring emissions and adjusting engine parameters in real-time, ensuring precise combustion control and reduced fuel consumption. Open-loop control relies on predefined settings without feedback, often leading to suboptimal fuel use and higher emissions under varying conditions. Advanced closed-loop strategies incorporate sensors for oxygen and exhaust gases, enabling dynamic adaptations that improve fuel economy and meet stringent emission standards.

Sensor Technology in Emission Systems

Closed-loop control systems in emission management leverage advanced sensor technology, such as oxygen sensors and NOx sensors, to continuously monitor exhaust gases and adjust fuel injection and air intake for optimal combustion. These real-time sensor inputs enable precise control of emission levels, reducing pollutants more effectively than open-loop systems, which rely on predetermined settings without sensor feedback. The integration of robust sensor technology in closed-loop controls significantly enhances compliance with stringent emission standards by dynamically responding to varying engine conditions.

Maintenance and Troubleshooting Considerations

Closed-loop control systems enhance emission reduction by continuously monitoring sensors and automatically adjusting operations, reducing the need for frequent manual maintenance. Open-loop control systems require regular troubleshooting and manual calibration to address sensor drift and system changes that can lead to increased emissions. Effective maintenance in closed-loop systems involves software updates and sensor diagnostics, while open-loop systems depend heavily on periodic physical inspections and adjustments.

Future Trends in Automotive Emission Control

Closed-loop control systems in automotive emission control utilize real-time feedback from sensors to precisely adjust air-fuel mixture, significantly reducing pollutants such as NOx and CO2. Open-loop control lacks sensor feedback, making it less adaptive to changing engine conditions and emissions. Future trends emphasize advanced closed-loop systems integrating artificial intelligence and machine learning algorithms to optimize emissions dynamically, meeting stringent global regulations and improving fuel efficiency.

Closed-loop control vs Open-loop control Infographic

cardiffo.com

cardiffo.com