Lean burn emissions typically produce lower carbon dioxide and higher nitrogen oxides compared to stoichiometric emissions due to excess air in the combustion process. Stoichiometric combustion achieves a precise air-to-fuel ratio, resulting in balanced emissions but often higher carbon monoxide and unburned hydrocarbons. Optimizing lean burn engines involves controlling nitrogen oxide formation while benefiting from improved fuel efficiency and reduced greenhouse gases.

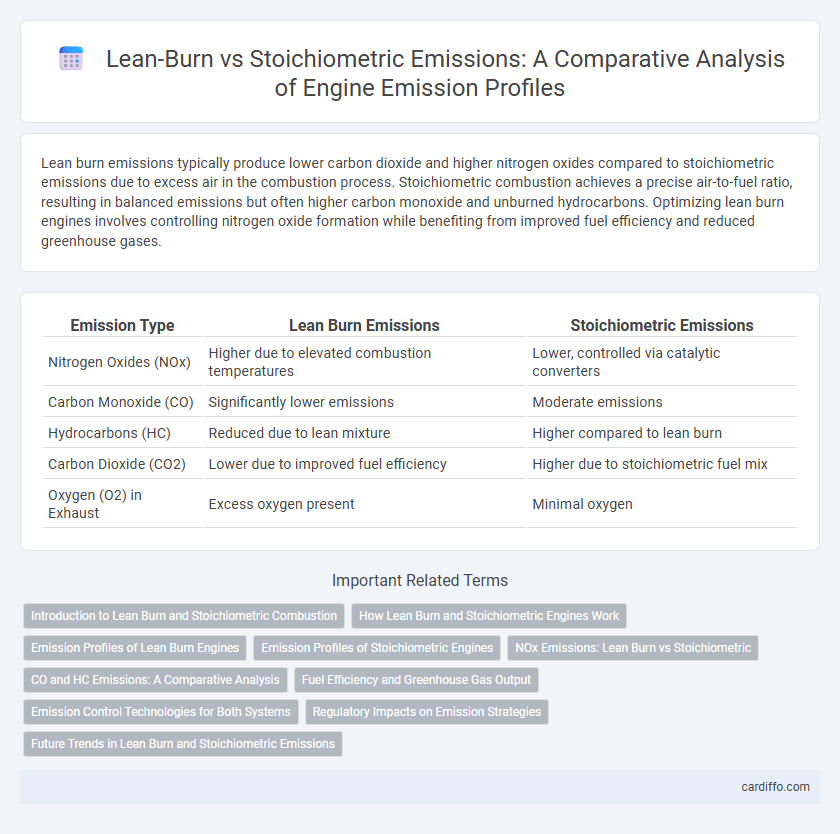

Table of Comparison

| Emission Type | Lean Burn Emissions | Stoichiometric Emissions |

|---|---|---|

| Nitrogen Oxides (NOx) | Higher due to elevated combustion temperatures | Lower, controlled via catalytic converters |

| Carbon Monoxide (CO) | Significantly lower emissions | Moderate emissions |

| Hydrocarbons (HC) | Reduced due to lean mixture | Higher compared to lean burn |

| Carbon Dioxide (CO2) | Lower due to improved fuel efficiency | Higher due to stoichiometric fuel mix |

| Oxygen (O2) in Exhaust | Excess oxygen present | Minimal oxygen |

Introduction to Lean Burn and Stoichiometric Combustion

Lean burn combustion operates with an excess of air compared to fuel, resulting in lower nitrogen oxide (NOx) and carbon monoxide (CO) emissions due to more complete oxidation. In contrast, stoichiometric combustion uses an ideal air-to-fuel ratio, balancing fuel and oxygen precisely to optimize catalytic converter efficiency but often produces higher NOx emissions. Understanding the differences between lean burn and stoichiometric combustion is essential for selecting appropriate engine control strategies to meet emission regulations.

How Lean Burn and Stoichiometric Engines Work

Lean burn engines operate with excess air, resulting in combustion that reduces carbon monoxide (CO) and hydrocarbon (HC) emissions by promoting more complete fuel oxidation. Stoichiometric engines maintain an ideal air-fuel ratio of approximately 14.7:1, optimizing catalytic converter efficiency to minimize nitrogen oxides (NOx), CO, and HC emissions simultaneously. The lean burn process achieves lower CO and HC but can increase NOx, while stoichiometric combustion balances emissions through precise control of the air-fuel mixture and advanced after-treatment systems.

Emission Profiles of Lean Burn Engines

Lean burn engines operate with an excess of air, resulting in lower carbon monoxide (CO) and hydrocarbon (HC) emissions compared to stoichiometric engines that run at an ideal air-fuel ratio. The increased oxygen availability in lean burn combustion promotes more complete oxidation, significantly reducing CO and HC but can lead to higher nitrogen oxides (NOx) due to elevated combustion temperatures. Advances in exhaust aftertreatment technologies, such as selective catalytic reduction (SCR), are critical for controlling NOx emissions while maintaining the high fuel efficiency advantages of lean burn engines.

Emission Profiles of Stoichiometric Engines

Stoichiometric engines operate with an ideal air-fuel ratio of approximately 14.7:1, optimizing complete combustion and resulting in balanced emissions of NOx, CO, and unburned hydrocarbons. Emission profiles of stoichiometric engines typically show lower hydrocarbon and CO levels due to effective catalytic converter operation, but higher NOx emissions compared to lean burn engines due to elevated combustion temperatures. The precise control of fuel injection and exhaust gas recirculation in stoichiometric engines helps maintain regulatory compliance while minimizing environmental impact.

NOx Emissions: Lean Burn vs Stoichiometric

Lean burn engines typically produce lower carbon monoxide and hydrocarbon emissions but generate higher nitrogen oxides (NOx) due to elevated combustion temperatures and excess oxygen. Stoichiometric engines maintain an ideal air-fuel ratio that enables more efficient catalytic converter operation, resulting in significantly reduced NOx emissions. Advanced NOx aftertreatment systems are often necessary for lean burn engines to meet stringent emission standards.

CO and HC Emissions: A Comparative Analysis

Lean burn engines typically produce lower carbon monoxide (CO) emissions due to the excess oxygen that promotes more complete combustion, reducing the amount of unburned fuel. Hydrocarbon (HC) emissions can be higher in lean burn conditions because lower combustion temperatures sometimes prevent complete oxidation of all hydrocarbons. Stoichiometric engines, operating with ideal air-fuel mixtures, usually emit higher CO levels but lower HC emissions, as the balanced mixture facilitates more efficient oxidation of hydrocarbons while occasionally allowing incomplete combustion of carbon monoxide.

Fuel Efficiency and Greenhouse Gas Output

Lean burn emissions typically result in higher fuel efficiency by utilizing excess air during combustion, which promotes more complete fuel oxidation and reduces fuel consumption. This results in lower carbon dioxide (CO2) emissions per unit of energy generated compared to stoichiometric combustion, which uses a precise air-fuel ratio and often leads to higher greenhouse gas output. However, lean burn conditions can increase nitrogen oxides (NOx) emissions, necessitating advanced after-treatment technologies to meet environmental regulations.

Emission Control Technologies for Both Systems

Lean burn engines produce lower NOx emissions due to excess air but face challenges controlling particulates, requiring advanced emission control technologies such as lean NOx traps (LNT) and selective catalytic reduction (SCR) systems. Stoichiometric combustion allows precise control of air-fuel ratio enabling efficient three-way catalysts (TWC) to simultaneously reduce NOx, CO, and HC emissions. Combining these technologies optimizes emission control by addressing the distinct pollutant profiles inherent in both lean burn and stoichiometric engine systems.

Regulatory Impacts on Emission Strategies

Lean burn emissions typically produce lower nitrogen oxides (NOx) and carbon dioxide (CO2) levels compared to stoichiometric combustion, aiding compliance with stringent regulatory emission limits such as Euro 7 and EPA Tier 3 standards. Regulatory frameworks promote the adoption of lean burn strategies for reduced greenhouse gas emissions and improved fuel efficiency, pressing manufacturers to optimize engine calibration and after-treatment technologies. However, challenges persist in controlling particulate matter (PM) and unburned hydrocarbons (UHC) under lean burn conditions, driving ongoing innovation in emissions control systems and policy adaptations.

Future Trends in Lean Burn and Stoichiometric Emissions

Future trends in lean burn emissions emphasize advanced combustion control and improved sensor technologies to enhance fuel efficiency and reduce NOx levels, targeting stricter environmental standards. Stoichiometric emissions are evolving with the integration of three-way catalysts and hybrid systems to optimize oxidation and reduction reactions, minimizing CO, HC, and NOx pollutants. Both approaches are converging through electrification and real-time adaptive engine management to achieve lower overall emissions and comply with global regulations.

Lean burn emissions vs Stoichiometric emissions Infographic

cardiffo.com

cardiffo.com