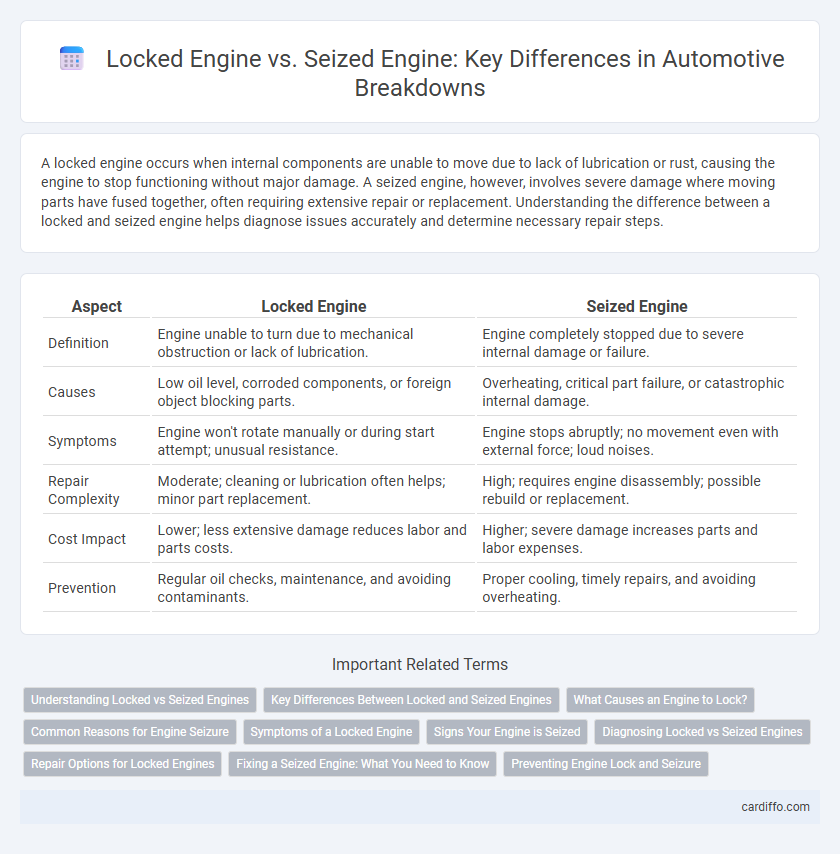

A locked engine occurs when internal components are unable to move due to lack of lubrication or rust, causing the engine to stop functioning without major damage. A seized engine, however, involves severe damage where moving parts have fused together, often requiring extensive repair or replacement. Understanding the difference between a locked and seized engine helps diagnose issues accurately and determine necessary repair steps.

Table of Comparison

| Aspect | Locked Engine | Seized Engine |

|---|---|---|

| Definition | Engine unable to turn due to mechanical obstruction or lack of lubrication. | Engine completely stopped due to severe internal damage or failure. |

| Causes | Low oil level, corroded components, or foreign object blocking parts. | Overheating, critical part failure, or catastrophic internal damage. |

| Symptoms | Engine won't rotate manually or during start attempt; unusual resistance. | Engine stops abruptly; no movement even with external force; loud noises. |

| Repair Complexity | Moderate; cleaning or lubrication often helps; minor part replacement. | High; requires engine disassembly; possible rebuild or replacement. |

| Cost Impact | Lower; less extensive damage reduces labor and parts costs. | Higher; severe damage increases parts and labor expenses. |

| Prevention | Regular oil checks, maintenance, and avoiding contaminants. | Proper cooling, timely repairs, and avoiding overheating. |

Understanding Locked vs Seized Engines

A locked engine occurs when internal components cannot move due to mechanical obstruction, often caused by sudden impact or extreme wear, preventing the engine from turning over. A seized engine results from severe damage such as overheating, where metal parts fuse together, causing irreversible damage that immobilizes the piston and crankshaft. Understanding the distinction between these conditions is crucial for accurate diagnosis and determining whether repair or replacement is necessary.

Key Differences Between Locked and Seized Engines

A locked engine occurs when internal engine components are unable to move due to mechanical restrictions like a broken timing belt or rod, while a seized engine results from severe damage often caused by lack of lubrication leading to metal parts fusing together. Locked engines may still allow some rotation or movement with external assistance, but seized engines are completely immobile. Understanding these differences is crucial for accurate diagnosis and determining the extent of engine repair or replacement needed.

What Causes an Engine to Lock?

An engine locks primarily due to insufficient lubrication, causing metal components to overheat and fuse together. Overheating from coolant system failure or prolonged overheating can warp engine parts, resulting in a locked piston or crankshaft. Mechanical failures such as a broken timing belt, seized bearings, or severe internal wear also contribute to engine seizure and locking.

Common Reasons for Engine Seizure

Common reasons for engine seizure include severe oil starvation, causing inadequate lubrication and excessive friction between moving parts, and overheating, which leads to metal expansion and warping. Contaminated or degraded engine oil can result in sludge buildup, restricting oil flow and causing internal damage. Mechanical failures such as broken timing belts or piston seizures from lack of maintenance also contribute significantly to engine seizure.

Symptoms of a Locked Engine

A locked engine exhibits symptoms such as an inability to turn over when attempting to start the vehicle, unusual resistance or complete immobility when manually rotating the crankshaft, and a sudden grinding noise if forced. Other signs include an absence of oil pressure or low oil levels, as well as overheating issues due to lack of movement. Diagnostic tools can detect locked engine conditions by monitoring engine compression and sensor feedback.

Signs Your Engine is Seized

A seized engine typically exhibits signs such as the inability to turn the crankshaft manually, a sudden engine stop during operation, and abnormal noises like grinding or clanking when attempting to start the vehicle. Other indicators include smoke coming from the engine bay, a burning smell, and dramatically low oil pressure on the gauge. Recognizing these symptoms promptly can prevent further damage and costly repairs, distinguishing a seized engine from a locked engine that may still move but won't start.

Diagnosing Locked vs Seized Engines

Diagnosing locked versus seized engines requires understanding the underlying causes and symptoms; a locked engine typically occurs due to mechanical obstruction or internal component failure, whereas a seized engine results from a total lack of lubrication causing metal parts to fuse. Diagnostic steps include attempting to manually rotate the crankshaft and checking for fluid levels, with seized engines often showing signs of overheating or oil depletion. Using diagnostic tools like an engine analyzer or compression tester helps differentiate the severity of the issue, guiding necessary repair or replacement actions.

Repair Options for Locked Engines

Repair options for locked engines typically involve freeing the engine by applying penetrating oil to loosen seized components or manually turning the crankshaft with a breaker bar to restore movement. In more severe cases, disassembling key parts such as the pistons, connecting rods, or crankshaft may be necessary to identify damage and replace worn or broken components. Preventive maintenance and timely lubrication can reduce the risk of lockup, potentially minimizing future repair costs.

Fixing a Seized Engine: What You Need to Know

Fixing a seized engine involves addressing the lack of lubrication or overheating that caused internal components to fuse together. Key steps include assessing engine damage, using penetrating oil to free stuck parts, and carefully attempting manual rotation to restore movement. In severe cases, professional disassembly and component replacement may be necessary to fully repair the seized engine.

Preventing Engine Lock and Seizure

Preventing engine lock and seizure requires regular maintenance, including timely oil changes and ensuring proper coolant levels to maintain optimal engine temperature. Using high-quality lubricants reduces friction and wear, while avoiding prolonged idling and overheating minimizes the risk of internal engine damage. Monitoring engine performance and addressing unusual noises or temperature spikes promptly can prevent costly breakdowns associated with locked or seized engines.

Locked engine vs seized engine Infographic

cardiffo.com

cardiffo.com