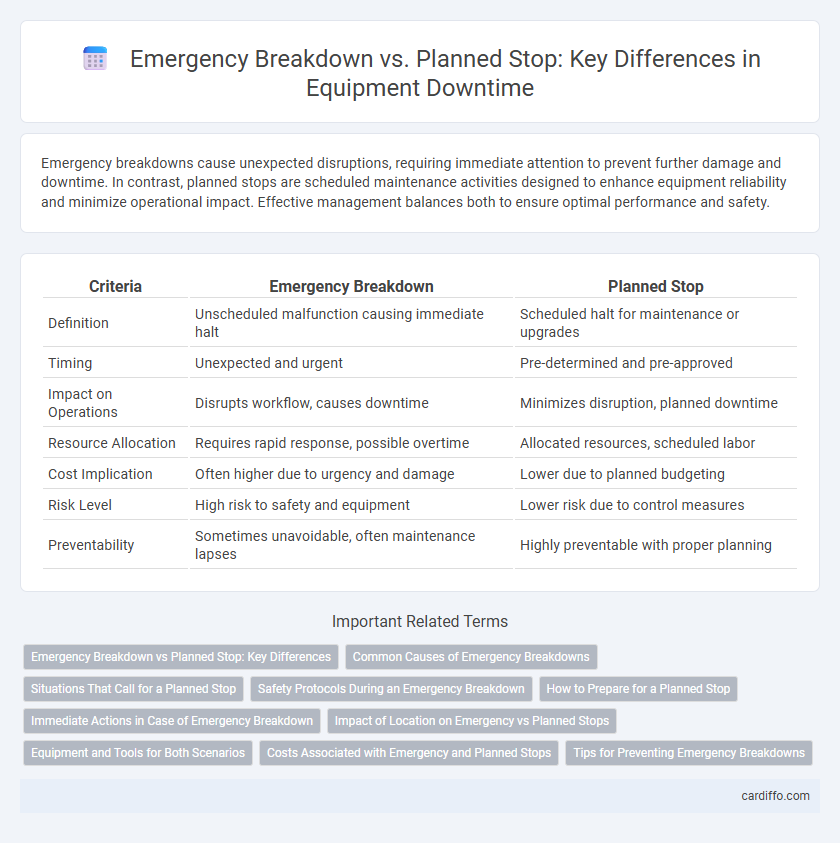

Emergency breakdowns cause unexpected disruptions, requiring immediate attention to prevent further damage and downtime. In contrast, planned stops are scheduled maintenance activities designed to enhance equipment reliability and minimize operational impact. Effective management balances both to ensure optimal performance and safety.

Table of Comparison

| Criteria | Emergency Breakdown | Planned Stop |

|---|---|---|

| Definition | Unscheduled malfunction causing immediate halt | Scheduled halt for maintenance or upgrades |

| Timing | Unexpected and urgent | Pre-determined and pre-approved |

| Impact on Operations | Disrupts workflow, causes downtime | Minimizes disruption, planned downtime |

| Resource Allocation | Requires rapid response, possible overtime | Allocated resources, scheduled labor |

| Cost Implication | Often higher due to urgency and damage | Lower due to planned budgeting |

| Risk Level | High risk to safety and equipment | Lower risk due to control measures |

| Preventability | Sometimes unavoidable, often maintenance lapses | Highly preventable with proper planning |

Emergency Breakdown vs Planned Stop: Key Differences

Emergency breakdowns occur unexpectedly and require immediate attention to minimize operational downtime, often leading to unplanned costs and safety risks. Planned stops are scheduled maintenance or operational pauses designed to prevent breakdowns, optimize performance, and control expenses effectively. Understanding the distinction between emergency breakdowns and planned stops is crucial for improving asset management and operational reliability.

Common Causes of Emergency Breakdowns

Emergency breakdowns commonly result from sudden mechanical failures such as engine overheating, battery failure, or broken belts. Electrical system faults, including alternator or starter motor issues, also frequently cause unexpected stoppages. Tire blowouts and brake system malfunctions contribute significantly to unplanned vehicle downtime, requiring immediate roadside attention.

Situations That Call for a Planned Stop

Situations that call for a planned stop include routine maintenance, equipment inspections, and software updates to prevent unexpected failures and optimize operational efficiency. Scheduled stops allow technicians to address wear and tear, replace parts proactively, and implement system upgrades without disrupting production flow. Planning these stops minimizes downtime, reduces emergency breakdown risks, and enhances overall safety and reliability.

Safety Protocols During an Emergency Breakdown

Emergency breakdowns require immediate activation of safety protocols to protect personnel and equipment, including isolating power sources and securing the area to prevent accidents. Unlike planned stops, these unexpected events demand rapid communication with emergency response teams and real-time risk assessments to mitigate hazards. Adherence to established emergency shutdown procedures and use of personal protective equipment (PPE) are critical for minimizing injury and ensuring operational safety.

How to Prepare for a Planned Stop

Preparing for a planned stop involves thorough maintenance scheduling, ensuring all necessary tools and replacement parts are available to minimize downtime. Detailed communication with the operations team is essential to coordinate the timing and scope of the stop, allowing for controlled shutdown and restart procedures. Implementing checklists and pre-stop inspections helps identify potential issues in advance, enhancing safety and operational efficiency.

Immediate Actions in Case of Emergency Breakdown

In the event of an emergency breakdown, immediate actions include halting all operations to ensure safety and isolating the affected equipment to prevent further damage. Rapid communication with maintenance teams accelerates diagnosis and repair, minimizing downtime. Implementing emergency protocols and using backup systems maintain operational continuity during the breakdown resolution process.

Impact of Location on Emergency vs Planned Stops

Emergency breakdowns often occur unexpectedly and can be significantly influenced by the location's accessibility and infrastructure quality, impacting the speed of repairs and safety measures. Planned stops are strategically scheduled in locations optimized for resource availability and minimal disruption, ensuring smoother operational continuity. Proximity to maintenance facilities and transportation links plays a critical role in reducing downtime during both emergency and planned interventions.

Equipment and Tools for Both Scenarios

Emergency breakdowns demand immediate access to specialized diagnostic tools and quick-acting repair equipment to minimize downtime and prevent further damage. Planned stops allow the use of comprehensive maintenance kits, calibrated instruments, and scheduled inspection devices that ensure thorough servicing and optimal equipment performance. Both scenarios require organized tool management systems and trained personnel to execute repairs efficiently and maintain operational continuity.

Costs Associated with Emergency and Planned Stops

Emergency breakdowns result in significantly higher costs due to unplanned downtime, urgent repairs, and potential production losses, often exceeding planned maintenance expenses by 30-50%. Planned stops allow for scheduled maintenance activities, optimizing resource allocation and minimizing disruption, thereby reducing overall operational costs. Companies implementing predictive maintenance strategies report up to 25% cost savings by decreasing emergency breakdown frequency and extending equipment lifespan.

Tips for Preventing Emergency Breakdowns

Emergency breakdowns cause unexpected downtime and significant repair costs, disrupting operations and reducing productivity. Implementing regular maintenance schedules, conducting thorough equipment inspections, and using predictive analytics can significantly reduce the risk of emergency breakdowns. Prioritizing early fault detection and staff training on emergency protocols enhances system reliability and minimizes costly disruptions.

Emergency breakdown vs planned stop Infographic

cardiffo.com

cardiffo.com