Hydraulic lock occurs when liquid enters the engine cylinders, preventing piston movement and causing severe damage, while vapor lock happens when fuel vaporizes in the fuel system, disrupting fuel flow and leading to engine stalling. Both issues cause engine breakdowns but differ in their causes and symptoms. Proper maintenance and avoiding overheating can help prevent hydraulic lock and vapor lock in vehicle engines.

Table of Comparison

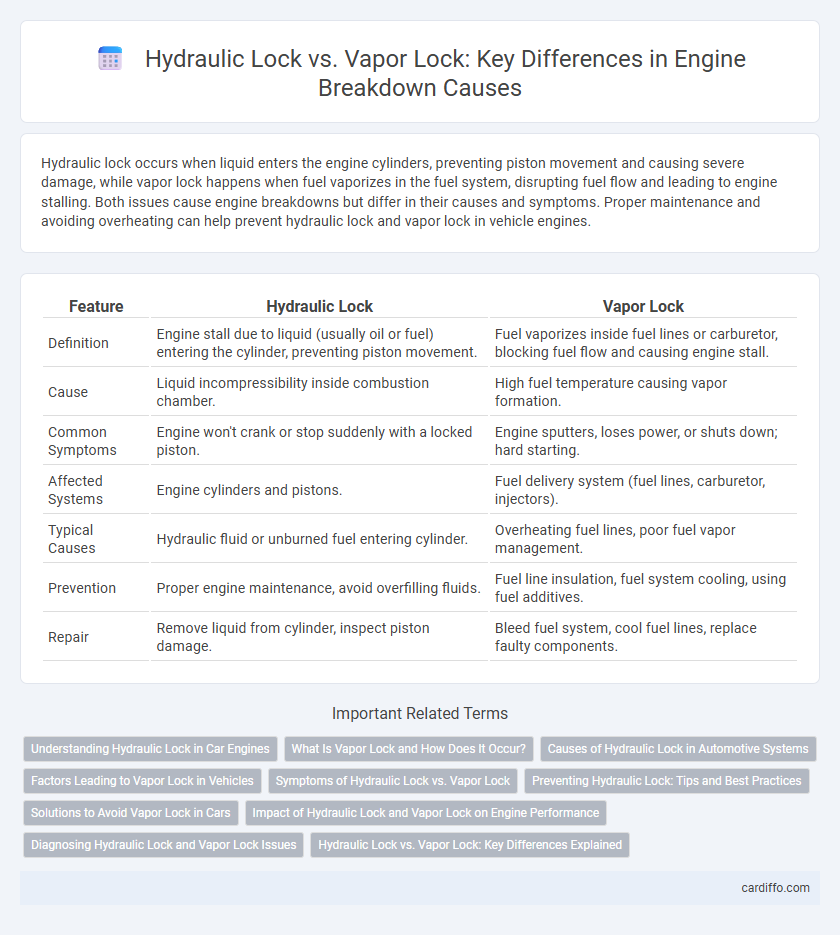

| Feature | Hydraulic Lock | Vapor Lock |

|---|---|---|

| Definition | Engine stall due to liquid (usually oil or fuel) entering the cylinder, preventing piston movement. | Fuel vaporizes inside fuel lines or carburetor, blocking fuel flow and causing engine stall. |

| Cause | Liquid incompressibility inside combustion chamber. | High fuel temperature causing vapor formation. |

| Common Symptoms | Engine won't crank or stop suddenly with a locked piston. | Engine sputters, loses power, or shuts down; hard starting. |

| Affected Systems | Engine cylinders and pistons. | Fuel delivery system (fuel lines, carburetor, injectors). |

| Typical Causes | Hydraulic fluid or unburned fuel entering cylinder. | Overheating fuel lines, poor fuel vapor management. |

| Prevention | Proper engine maintenance, avoid overfilling fluids. | Fuel line insulation, fuel system cooling, using fuel additives. |

| Repair | Remove liquid from cylinder, inspect piston damage. | Bleed fuel system, cool fuel lines, replace faulty components. |

Understanding Hydraulic Lock in Car Engines

Hydraulic lock occurs when a liquid, such as coolant or fuel, enters a car engine's combustion chamber, preventing the piston from completing its cycle due to the incompressibility of fluids. This condition can cause severe engine damage, including bent connecting rods or cracked engine blocks, as the sudden pressure surge strains internal components. Understanding hydraulic lock is crucial for diagnosing engine failures caused by fluid intrusion during operation.

What Is Vapor Lock and How Does It Occur?

Vapor lock occurs when fuel vaporizes within the fuel delivery system, disrupting the continuous flow of liquid fuel to the engine. This phenomenon typically arises at high engine temperatures or under intense heat conditions, causing fuel to boil and create vapor bubbles that block fuel lines. Unlike hydraulic lock, which involves liquid flooding the engine cylinders, vapor lock prevents the engine from receiving adequate fuel, leading to stalling or failure to start.

Causes of Hydraulic Lock in Automotive Systems

Hydraulic lock in automotive systems occurs when incompressible fluid, such as engine oil or coolant, enters the combustion chamber, preventing piston movement and causing engine seizure. Common causes include coolant leaks from a blown head gasket, cylinder head cracks, or excessive oil entering the combustion chamber through worn piston rings or valve seals. These issues disrupt normal engine operation by creating a fluid barrier that piston compression cannot overcome, leading to severe mechanical damage.

Factors Leading to Vapor Lock in Vehicles

Vapor lock in vehicles primarily occurs when fuel temperature rises, causing it to vaporize within the fuel delivery system, disrupting smooth fuel flow. High under-hood temperatures, low atmospheric pressure, and improper fuel mixture contribute significantly to vapor lock conditions. Unlike hydraulic lock, vapor lock involves fuel vapor formation that impairs engine combustion efficiency, often triggered by excessive heat and inadequate cooling mechanisms.

Symptoms of Hydraulic Lock vs. Vapor Lock

Hydraulic lock symptoms include a sudden engine stall or failure to start, accompanied by unusual engine noise or inability to turn over due to liquid in the cylinders. Vapor lock symptoms manifest as engine hesitation, stalling during hot conditions, and difficulty starting when the fuel vaporizes in the fuel lines. Both conditions disrupt engine performance but differ in mechanical cause and environmental triggers.

Preventing Hydraulic Lock: Tips and Best Practices

Preventing hydraulic lock involves regularly inspecting engine components for fluid leaks and ensuring proper maintenance of seals and gaskets to avoid liquid intrusion into the combustion chamber. Using high-quality engine oil and practicing proper warm-up routines can reduce condensation buildup, minimizing the risk of hydraulic lock. Incorporating drainage plugs and checking for coolant system integrity also help maintain optimal engine function and prevent costly breakdowns.

Solutions to Avoid Vapor Lock in Cars

Using fuel additives designed to increase the boiling point of gasoline effectively prevents vapor lock in cars by reducing fuel vaporization in hot conditions. Installing heat shields and insulating fuel lines minimize exposure to engine heat, maintaining consistent fuel temperatures and flow. Regular maintenance of the fuel system, including replacing worn fuel pumps and checking for air leaks, ensures optimal pressure and prevents vapor formation that leads to vapor lock.

Impact of Hydraulic Lock and Vapor Lock on Engine Performance

Hydraulic lock causes immediate engine seizure by preventing piston movement when incompressible fluid, usually coolant or oil, enters the combustion chamber, leading to severe mechanical damage. Vapor lock results from fuel vaporization in the fuel line or carburetor, causing fuel flow interruption and engine stalling, significantly reducing performance and drivability. Both conditions drastically impair engine reliability, with hydraulic lock causing catastrophic failure and vapor lock inducing temporary but critical performance loss.

Diagnosing Hydraulic Lock and Vapor Lock Issues

Diagnosing hydraulic lock involves inspecting engine cylinders for unburned fuel or liquid coolant that prevents piston movement, often detected through a sudden engine stall or inability to turn over. Vapor lock diagnosis requires checking fuel lines and fuel pumps for vaporized fuel bubbles, usually indicated by sputtering, stalling, or difficulty starting in hot conditions. Accurate identification relies on observing symptoms during engine operation and performing pressure tests on fuel delivery and cylinder compression systems.

Hydraulic Lock vs. Vapor Lock: Key Differences Explained

Hydraulic lock occurs when liquid fuel or coolant enters the engine cylinder, preventing piston movement and causing engine stalling, while vapor lock results from fuel vaporizing in the fuel line, disrupting fuel flow and leading to engine hesitation or failure to start. Hydraulic lock is typically caused by coolant leaks or water ingestion, whereas vapor lock is influenced by high temperatures and low fuel pressure. Understanding these distinct mechanisms is crucial for diagnosing engine breakdowns and implementing appropriate repair strategies.

Hydraulic lock vs vapor lock Infographic

cardiffo.com

cardiffo.com