Fuel pump failure causes a complete loss of fuel pressure, preventing the engine from starting or running properly, while a clogged fuel filter restricts fuel flow, leading to poor engine performance and stalling. Symptoms of a failing fuel pump often include whining noises from the fuel tank and intermittent power loss, whereas a clogged fuel filter results in reduced acceleration and hesitation under load. Identifying the issue requires checking fuel pressure and inspecting the filter for debris to determine whether replacement or repair is necessary.

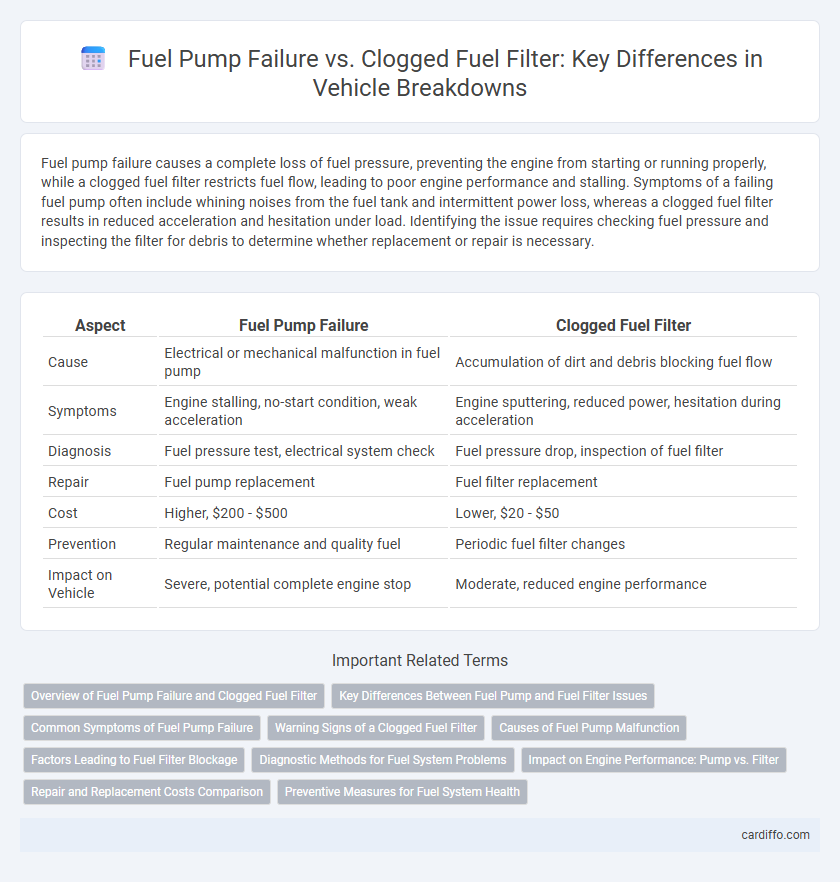

Table of Comparison

| Aspect | Fuel Pump Failure | Clogged Fuel Filter |

|---|---|---|

| Cause | Electrical or mechanical malfunction in fuel pump | Accumulation of dirt and debris blocking fuel flow |

| Symptoms | Engine stalling, no-start condition, weak acceleration | Engine sputtering, reduced power, hesitation during acceleration |

| Diagnosis | Fuel pressure test, electrical system check | Fuel pressure drop, inspection of fuel filter |

| Repair | Fuel pump replacement | Fuel filter replacement |

| Cost | Higher, $200 - $500 | Lower, $20 - $50 |

| Prevention | Regular maintenance and quality fuel | Periodic fuel filter changes |

| Impact on Vehicle | Severe, potential complete engine stop | Moderate, reduced engine performance |

Overview of Fuel Pump Failure and Clogged Fuel Filter

Fuel pump failure occurs when the pump responsible for delivering fuel from the tank to the engine ceases to function effectively, causing engine sputtering, loss of power, or complete stalling. A clogged fuel filter restricts fuel flow by trapping dirt and debris, leading to similar symptoms such as poor acceleration and engine misfires. Both issues disrupt the fuel supply but differ in root cause and repair complexity, making accurate diagnosis essential for timely vehicle restoration.

Key Differences Between Fuel Pump and Fuel Filter Issues

Fuel pump failure typically results in a complete loss of engine power due to the inability to deliver fuel, while a clogged fuel filter causes reduced engine performance and intermittent stalling by restricting fuel flow. The fuel pump is an active component powered by electricity, whereas the fuel filter is a passive part designed to trap debris and contaminants. Diagnosing the issue involves checking fuel pressure for pump failure and inspecting or replacing the fuel filter to resolve blockages.

Common Symptoms of Fuel Pump Failure

Fuel pump failure commonly manifests through symptoms such as engine sputtering at high speeds, difficulty starting the vehicle, and loss of power during acceleration. Another key indicator is an unusual whining noise coming from the fuel tank, signaling potential pump damage. These symptoms differ from those caused by a clogged fuel filter, which typically results in reduced engine performance and stalling at low speeds.

Warning Signs of a Clogged Fuel Filter

A clogged fuel filter often causes engine sputtering and reduced acceleration due to restricted fuel flow. Warning signs include difficulty starting the engine, frequent stalling, and decreased fuel efficiency. Ignoring these symptoms can lead to increased strain on the fuel pump and eventual breakdown.

Causes of Fuel Pump Malfunction

Fuel pump malfunction primarily results from electrical issues, worn-out components, or contamination caused by debris and rust in the fuel tank. Unlike a clogged fuel filter that restricts fuel flow, fuel pump failure often stems from overheating due to low fuel levels or a failing relay and wiring faults. Addressing causes such as sediment buildup, mechanical wear, and flawed electrical connections is crucial for diagnosing fuel pump failure accurately.

Factors Leading to Fuel Filter Blockage

Fuel filter blockage primarily results from contaminants such as dirt, rust, and debris accumulating in the fuel system over time. Poor-quality fuel and infrequent maintenance schedules exacerbate the clogging by allowing impurities to settle and restrict fuel flow. Environmental factors like moisture and sediment build-up also contribute significantly to the degradation and obstruction of fuel filters.

Diagnostic Methods for Fuel System Problems

Diagnostic methods for fuel system problems distinguish fuel pump failure from a clogged fuel filter by measuring fuel pressure using a gauge; low or no pressure typically indicates pump issues, while a slight pressure drop suggests filter blockage. Inspecting fuel flow by disconnecting the fuel line can reveal restrictions linked to a clogged filter, whereas irregular sounds or intermittent fuel delivery point to pump malfunction. Utilizing diagnostic scanners to check for error codes related to fuel system performance enhances accurate identification and resolution of these breakdowns.

Impact on Engine Performance: Pump vs. Filter

Fuel pump failure causes a significant drop in fuel pressure, leading to engine misfires, stalling, or failure to start due to insufficient fuel delivery. A clogged fuel filter restricts fuel flow gradually, resulting in reduced engine power, hesitation, and decreased acceleration without completely stopping engine operation. Engine performance deteriorates more abruptly and severely with pump failure compared to the slower, progressive impact of a clogged fuel filter.

Repair and Replacement Costs Comparison

Fuel pump failure repair typically ranges from $400 to $800 due to the labor-intensive replacement process and the pump's higher part cost, whereas clogged fuel filter replacement usually costs between $50 and $150, reflecting simpler access and lower component prices. Fuel pump issues often require diagnostic time and may involve additional fuel system inspection, increasing overall expenses, while fuel filter clogs are quicker to resolve with minimal diagnostic needs. Choosing repair or replacement depends on accurate diagnosis to avoid unnecessary costs, as misidentifying a clogged filter for a failing pump can lead to significantly higher repair bills.

Preventive Measures for Fuel System Health

Regularly replacing the fuel filter every 20,000 to 30,000 miles prevents clogging that can strain the fuel pump and cause breakdowns. Using high-quality fuel and additives helps maintain clean fuel injectors and reduces the risk of fuel pump failure. Routine fuel system inspections and prompt addressing of warning signs like sputtering or difficulty starting extend the lifespan of fuel system components and ensure reliable vehicle performance.

Fuel pump failure vs clogged fuel filter Infographic

cardiffo.com

cardiffo.com