A timing belt snap results in immediate engine failure due to the loss of synchronization between the camshaft and crankshaft, causing severe internal damage in interference engines. In contrast, serpentine belt slip primarily affects peripheral systems such as the alternator, power steering, and air conditioning, leading to reduced performance but typically not catastrophic engine damage. Prompt attention to timing belt wear and serpentine belt tension can prevent breakdowns and costly repairs.

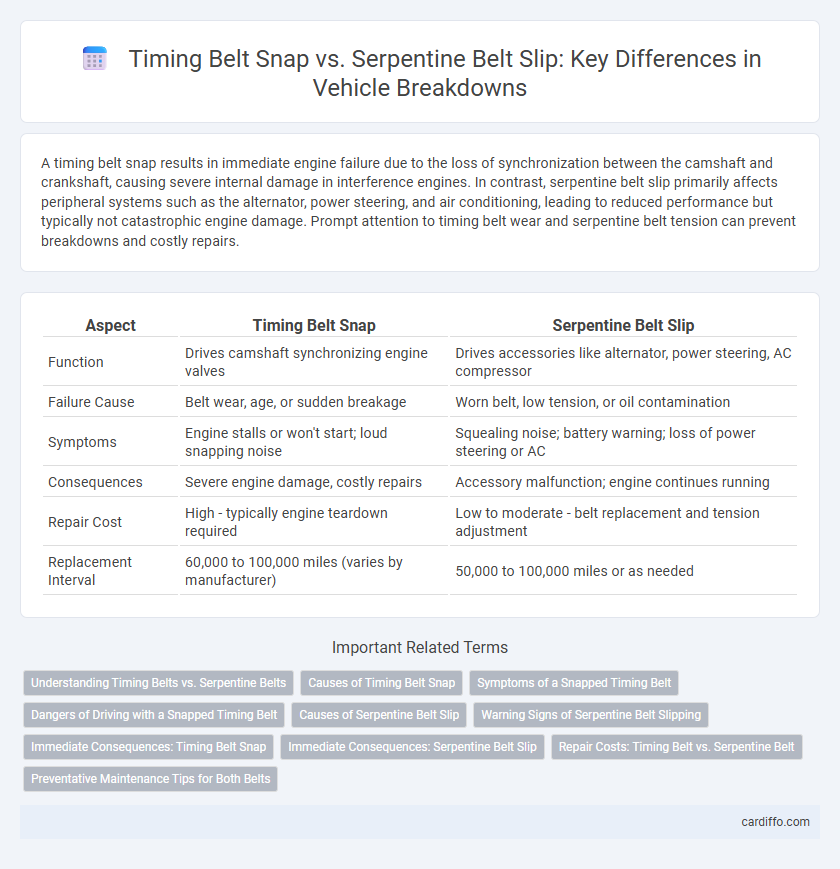

Table of Comparison

| Aspect | Timing Belt Snap | Serpentine Belt Slip |

|---|---|---|

| Function | Drives camshaft synchronizing engine valves | Drives accessories like alternator, power steering, AC compressor |

| Failure Cause | Belt wear, age, or sudden breakage | Worn belt, low tension, or oil contamination |

| Symptoms | Engine stalls or won't start; loud snapping noise | Squealing noise; battery warning; loss of power steering or AC |

| Consequences | Severe engine damage, costly repairs | Accessory malfunction; engine continues running |

| Repair Cost | High - typically engine teardown required | Low to moderate - belt replacement and tension adjustment |

| Replacement Interval | 60,000 to 100,000 miles (varies by manufacturer) | 50,000 to 100,000 miles or as needed |

Understanding Timing Belts vs. Serpentine Belts

Timing belts synchronize the engine's camshaft and crankshaft, ensuring precise valve timing critical for engine performance, while serpentine belts drive multiple peripheral devices like the alternator and power steering pump. A timing belt snap can cause severe engine damage due to valve and piston collisions, whereas a serpentine belt slip typically results in loss of accessory function and overheating without immediate engine failure. Understanding the distinct roles and failure risks of timing belts versus serpentine belts is essential for proper vehicle maintenance and avoiding costly breakdowns.

Causes of Timing Belt Snap

A timing belt snap primarily occurs due to excessive wear, improper tension, or oil contamination that degrades the belt material. Engine overheating and misaligned pulleys can also accelerate deterioration, leading to sudden failure. Neglecting regular maintenance intervals significantly increases the risk of timing belt breakage, causing severe engine damage.

Symptoms of a Snapped Timing Belt

A snapped timing belt causes the engine to suddenly lose power, resulting in a complete stall and failure to restart. Unlike serpentine belt slip, which may produce squealing noises and accessory malfunctions, timing belt failure often leads to severe engine damage due to improper valve timing. Key symptoms include jerky engine operation before failure, loud snapping sounds at the moment of breakage, and no response from the ignition system.

Dangers of Driving with a Snapped Timing Belt

Driving with a snapped timing belt causes catastrophic engine failure as the pistons and valves collide, leading to costly repairs or engine replacement. Unlike a slipping serpentine belt that affects accessories like the alternator or power steering, a broken timing belt halts engine operation immediately, increasing the risk of sudden breakdown and loss of vehicle control. Ignoring timing belt maintenance can result in severe mechanical damage, making prompt replacement critical for engine safety and reliability.

Causes of Serpentine Belt Slip

Serpentine belt slip is primarily caused by worn or glazed belts, which reduce friction and grip on the pulleys. Contaminants such as oil or coolant leaking onto the belt surface can also cause slippage by diminishing traction. Improper belt tension, whether too loose or misaligned pulleys, further contributes to serpentine belt slip by preventing consistent contact and power transmission.

Warning Signs of Serpentine Belt Slipping

Warning signs of serpentine belt slipping include a high-pitched squealing noise during engine start or acceleration, visible cracks or fraying on the belt surface, and a noticeable decrease in power steering responsiveness or alternator output. Engine overheating can occur as the belt fails to drive the water pump effectively. Prompt inspection and replacement prevent further breakdowns and costly repairs.

Immediate Consequences: Timing Belt Snap

A timing belt snap causes the engine to stop abruptly, leading to immediate loss of synchronization between the camshaft and crankshaft. This results in severe engine damage, including bent valves, piston strikes, and potential engine failure. In contrast to serpentine belt slip, which affects accessory functions, a timing belt snap disrupts critical engine timing with dire mechanical consequences.

Immediate Consequences: Serpentine Belt Slip

A serpentine belt slip immediately causes loss of power steering, making steering difficult and unsafe, along with potential overheating due to impaired water pump function. Electrical components like the alternator may also underperform, leading to battery drain and engine stalls. Prompt inspection and replacement are critical to prevent complete breakdown and costly repairs.

Repair Costs: Timing Belt vs. Serpentine Belt

Repair costs for a timing belt snap are typically higher than for a serpentine belt slip due to the extensive engine damage that can result from a timing belt failure. Timing belt replacement often ranges from $500 to $1,000 or more, including labor and parts, while serpentine belt repairs usually cost between $100 and $250. Failure to address a snapped timing belt promptly can lead to costly engine rebuilds, whereas a slipping serpentine belt generally causes less severe mechanical issues.

Preventative Maintenance Tips for Both Belts

Timing belt snap and serpentine belt slip both cause engine performance issues but require different preventative maintenance strategies. Regular inspection of the timing belt for cracks, wear, and proper tension every 60,000 to 100,000 miles prevents sudden failure, while serpentine belts benefit from checking for glazing, fraying, and ensuring proper pulley alignment to avoid slipping. Replacing belts at manufacturer-recommended intervals and maintaining proper tension are critical to extending belt lifespan and preventing costly breakdowns.

Timing belt snap vs serpentine belt slip Infographic

cardiffo.com

cardiffo.com