Valve grinding involves using an abrasive grinding tool to resurface the valve and valve seat, ensuring a tight seal and restoring engine compression. Valve lapping is a manual process where a rotating tool and abrasive compound are used to create a precise, polished seal between the valve face and seat. While valve grinding removes more material for severe wear, valve lapping is ideal for fine-tuning and minor surface imperfections.

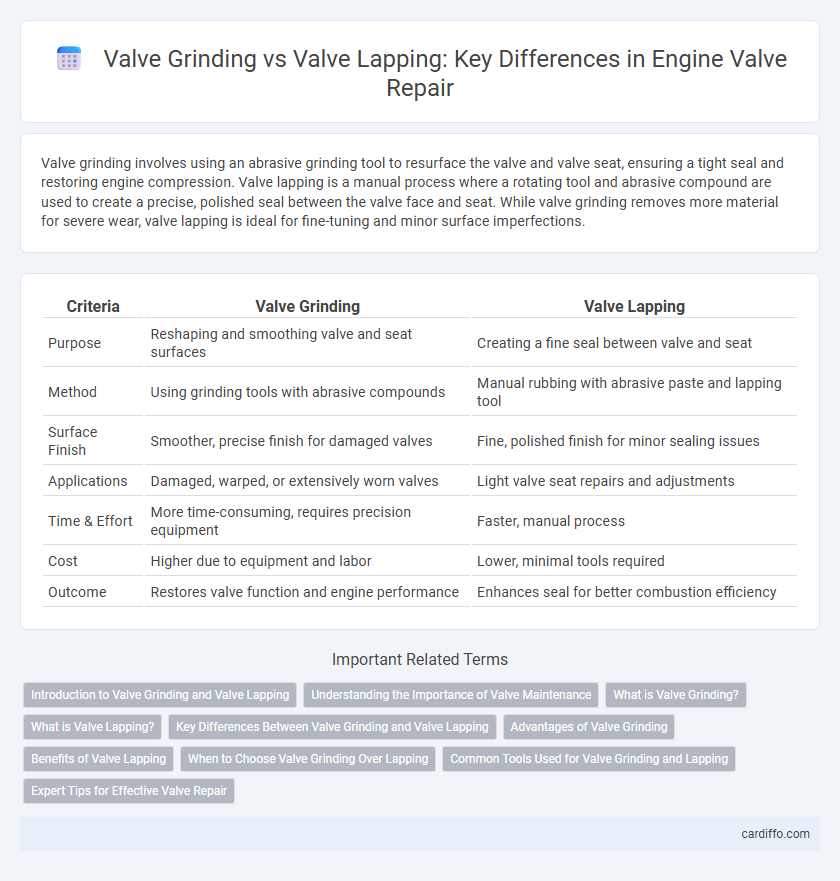

Table of Comparison

| Criteria | Valve Grinding | Valve Lapping |

|---|---|---|

| Purpose | Reshaping and smoothing valve and seat surfaces | Creating a fine seal between valve and seat |

| Method | Using grinding tools with abrasive compounds | Manual rubbing with abrasive paste and lapping tool |

| Surface Finish | Smoother, precise finish for damaged valves | Fine, polished finish for minor sealing issues |

| Applications | Damaged, warped, or extensively worn valves | Light valve seat repairs and adjustments |

| Time & Effort | More time-consuming, requires precision equipment | Faster, manual process |

| Cost | Higher due to equipment and labor | Lower, minimal tools required |

| Outcome | Restores valve function and engine performance | Enhances seal for better combustion efficiency |

Introduction to Valve Grinding and Valve Lapping

Valve grinding involves using an abrasive compound and a grinding tool to precisely reshape and seal the valve seat for optimal engine performance. Valve lapping is a more manual process that uses a fine abrasive paste and repetitive rubbing between the valve and seat to improve the seal and surface finish. Both techniques are essential for maintaining proper valve function and preventing leaks in internal combustion engines.

Understanding the Importance of Valve Maintenance

Valve grinding ensures a precise seal by removing surface imperfections on the valve and seat, improving engine compression and efficiency. Valve lapping, a manual process using abrasive paste, helps to create a smooth and tight seal between the valve and seat, preventing leaks and maintaining optimal engine performance. Regular valve maintenance, including grinding and lapping, extends engine life by ensuring proper combustion and reducing wear.

What is Valve Grinding?

Valve grinding is a precise repair process used to restore the contact surface between the valve and valve seat in an engine cylinder head. It involves using an abrasive compound and a specialized grinding tool to remove imperfections, ensuring a tight seal that prevents compression loss and improves engine performance. Proper valve grinding extends engine life by enhancing combustion efficiency and preventing leakage.

What is Valve Lapping?

Valve lapping is a precise engine repair technique used to create a tight seal between the valve and its seat by manually rubbing abrasive compounds onto the valve surface. This process improves compression and prevents leaks by smoothing out microscopic imperfections. It is typically performed during routine maintenance or when minor valve seat damage is detected.

Key Differences Between Valve Grinding and Valve Lapping

Valve grinding involves removing material from the valve seat for reshaping using abrasive tools, resulting in a precise, durable seal. Valve lapping is a fine-tuning process that smooths valve surfaces through manual rubbing with an abrasive paste, enhancing the valve's sealing ability without major material removal. Grinding corrects significant wear or damage, while lapping addresses minor imperfections and improves valve-seat contact.

Advantages of Valve Grinding

Valve grinding offers precise surface restoration, ensuring optimal valve-to-seat contact for improved engine compression and performance. It efficiently removes significant valve and seat wear or damage that valve lapping cannot address, extending engine lifespan. This method provides a more thorough and lasting seal, reducing the likelihood of leaks and enhancing overall engine reliability.

Benefits of Valve Lapping

Valve lapping provides superior sealing by creating a smooth, even surface between the valve and seat, improving engine compression and performance. This process removes minor imperfections and irregularities more effectively than valve grinding, ensuring a tighter fit and reducing the risk of leaks. Enhanced valve sealing achieved through valve lapping also contributes to increased fuel efficiency and reduced exhaust emissions.

When to Choose Valve Grinding Over Lapping

Valve grinding is preferred over lapping when seals are heavily worn, surfaces are pitted, or valve seats require reshaping to restore proper sealing. Grinding provides a precise and uniform finish, essential for high-performance engines or when ovality and warping exceed acceptable limits. Lapping is suitable for minor sealing imperfections but cannot correct significant valve or seat damage, making grinding the better choice for extensive repairs.

Common Tools Used for Valve Grinding and Lapping

Common tools used for valve grinding include a valve grinder machine, abrasive grinding wheels, and specialized mandrels designed to hold the valve securely. Valve lapping typically requires hand lapping sticks, a lapping compound made from fine abrasive paste, and a suction cup or lapping tool to rotate the valve back and forth. Both processes rely on precision tools that ensure proper valve seat contact and optimal engine performance.

Expert Tips for Effective Valve Repair

Valve grinding removes material to restore flatness and ensure proper sealing, ideal for valves with significant wear or damage. Valve lapping uses a fine abrasive compound to smooth minor imperfections and enhance valve seat contact, suitable for routine maintenance or minor repairs. Expert tips emphasize using precise measurement tools to assess valve and seat condition before choosing grinding or lapping, ensuring optimal engine performance and longevity.

Valve grinding vs Valve lapping Infographic

cardiffo.com

cardiffo.com