Mechanical fans generate airflow through belt-driven blades connected to the engine, offering reliable cooling without electrical components but requiring regular maintenance of belts and bearings. Electric fans use motors powered by the vehicle's electrical system to provide targeted cooling, improving fuel efficiency and allowing for variable speeds based on temperature sensors. Choosing between mechanical and electric fans depends on vehicle requirements, repair complexity, and energy consumption considerations.

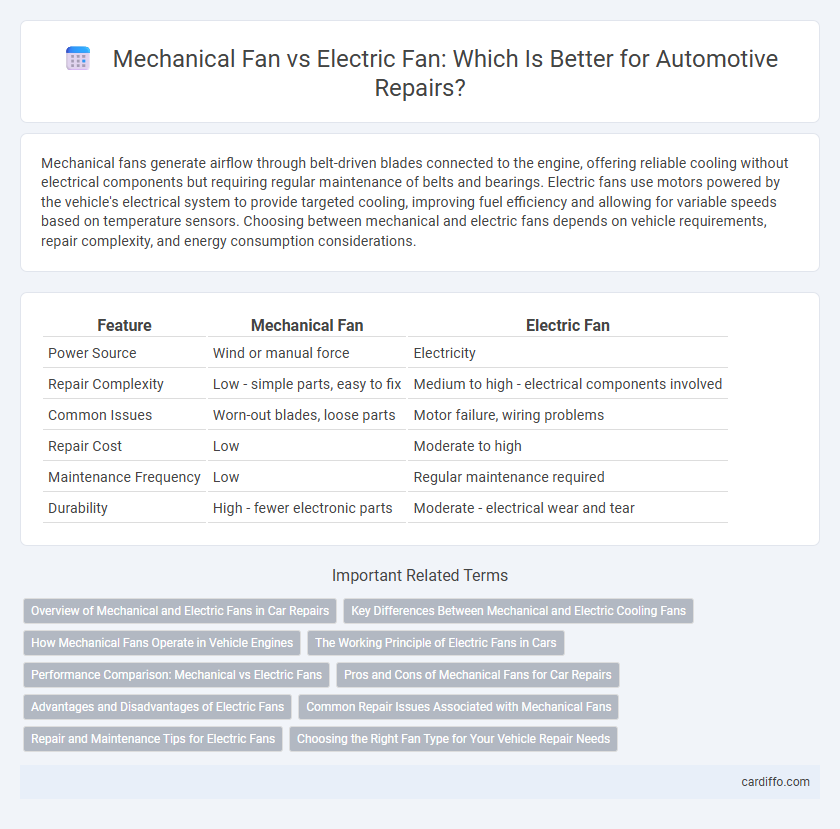

Table of Comparison

| Feature | Mechanical Fan | Electric Fan |

|---|---|---|

| Power Source | Wind or manual force | Electricity |

| Repair Complexity | Low - simple parts, easy to fix | Medium to high - electrical components involved |

| Common Issues | Worn-out blades, loose parts | Motor failure, wiring problems |

| Repair Cost | Low | Moderate to high |

| Maintenance Frequency | Low | Regular maintenance required |

| Durability | High - fewer electronic parts | Moderate - electrical wear and tear |

Overview of Mechanical and Electric Fans in Car Repairs

Mechanical fans in car repairs rely on engine-driven belts to cool the radiator, offering simplicity and durability but often consuming more engine power. Electric fans operate independently via an electric motor, providing precise temperature control and improved fuel efficiency by activating only when needed. Repair technicians prioritize diagnosing motor function and electrical connections for electric fans, while mechanical fan repairs often involve belt inspections and clutch replacements.

Key Differences Between Mechanical and Electric Cooling Fans

Mechanical fans rely on engine power transmitted via belts to operate, making them dependent on vehicle speed, while electric fans use independent electric motors powered by the battery, enabling consistent airflow regardless of engine RPM. Mechanical fans are typically less efficient and generate more noise, whereas electric fans offer precise temperature control and improved fuel efficiency by operating only when needed. Maintenance for mechanical fans involves belt and clutch inspections, while electric fans require monitoring of electrical components and connectors.

How Mechanical Fans Operate in Vehicle Engines

Mechanical fans in vehicle engines operate through a belt-driven system connected to the engine's crankshaft, enabling them to spin in direct proportion to engine speed. These fans draw air through the radiator to dissipate heat generated by the engine, maintaining optimal operating temperatures and preventing overheating. Unlike electric fans, mechanical fans rely solely on the engine's mechanical power, which can impact fuel efficiency and engine load during operation.

The Working Principle of Electric Fans in Cars

Electric fans in cars operate using an electric motor powered by the vehicle's battery, which drives the fan blades to circulate air and regulate engine temperature efficiently. Unlike mechanical fans linked directly to the engine's crankshaft via a belt, electric fans activate based on temperature sensors, allowing precise cooling without affecting engine performance. This system enhances fuel efficiency and reduces wear by running only when necessary, ensuring optimal engine cooling during varying operational conditions.

Performance Comparison: Mechanical vs Electric Fans

Mechanical fans rely on belts and pulleys, offering consistent airflow with relatively low power consumption but require regular maintenance to prevent wear and tear. Electric fans use direct-drive motors, providing higher efficiency, quieter operation, and adjustable speeds, resulting in improved energy performance and reduced operational costs. Performance benchmarks show electric fans outperform mechanical fans in airflow rate and durability, making them preferable for modern HVAC systems.

Pros and Cons of Mechanical Fans for Car Repairs

Mechanical fans in car repairs offer the advantage of being directly driven by the engine, providing consistent cooling without relying on electrical components, which enhances reliability in harsh conditions. However, they consume engine power, potentially reducing fuel efficiency and overall vehicle performance. Maintenance can be simpler due to fewer electrical parts, but mechanical fans are less adjustable and less efficient at varying speeds compared to electric fans.

Advantages and Disadvantages of Electric Fans

Electric fans offer energy efficiency and quiet operation, making them ideal for indoor use and extended running times. Their adjustable speed settings and portability enhance user convenience, but they rely on electrical power, which limits usage during outages or in areas without electricity. Maintenance is generally low due to fewer moving parts compared to mechanical fans, though the initial cost can be higher.

Common Repair Issues Associated with Mechanical Fans

Mechanical fans commonly encounter issues such as worn-out bearings, which cause excessive noise and reduced efficiency, and belt wear or misalignment, leading to decreased airflow and overheating. Shaft misalignment can result in vibration problems, accelerating wear on components and causing premature failure. Regular maintenance of lubrication and tension adjustments is essential to prevent these mechanical failures and extend the fan's operational lifespan.

Repair and Maintenance Tips for Electric Fans

Electric fans require regular cleaning of the blades and motor housing to prevent dust buildup that can cause overheating and motor failure. Lubricate the motor bearings every six months to ensure smooth operation and reduce wear and tear. Regularly check the power cord and switch for damage, replacing worn components promptly to avoid electrical hazards and maintain optimal performance.

Choosing the Right Fan Type for Your Vehicle Repair Needs

Mechanical fans, driven by the engine via belts, offer reliable cooling performance under high-load conditions and are easier to repair with basic tools, making them ideal for older vehicles or heavy-duty applications. Electric fans provide precise temperature control through thermostatic sensors, improve fuel efficiency by reducing engine load, and are preferable for modern vehicles requiring efficient cooling and quieter operation. Assess your vehicle's cooling system specifications, repair complexity, and performance needs to determine whether a mechanical or electric fan best suits your automotive repair requirements.

Mechanical fan vs Electric fan Infographic

cardiffo.com

cardiffo.com