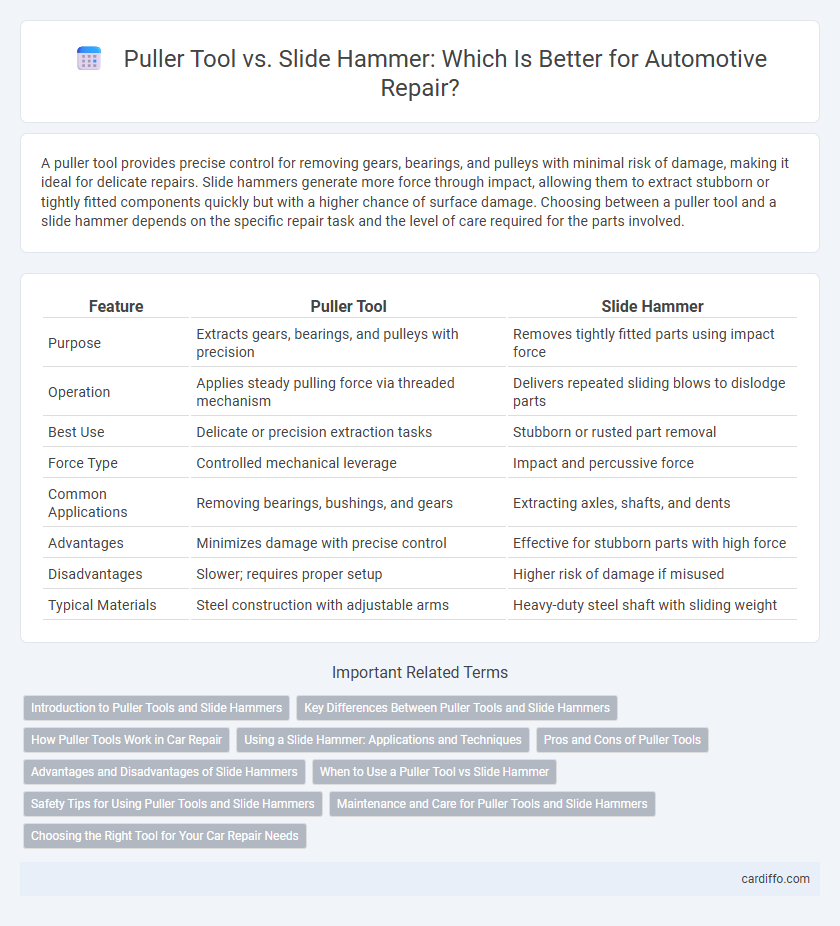

A puller tool provides precise control for removing gears, bearings, and pulleys with minimal risk of damage, making it ideal for delicate repairs. Slide hammers generate more force through impact, allowing them to extract stubborn or tightly fitted components quickly but with a higher chance of surface damage. Choosing between a puller tool and a slide hammer depends on the specific repair task and the level of care required for the parts involved.

Table of Comparison

| Feature | Puller Tool | Slide Hammer |

|---|---|---|

| Purpose | Extracts gears, bearings, and pulleys with precision | Removes tightly fitted parts using impact force |

| Operation | Applies steady pulling force via threaded mechanism | Delivers repeated sliding blows to dislodge parts |

| Best Use | Delicate or precision extraction tasks | Stubborn or rusted part removal |

| Force Type | Controlled mechanical leverage | Impact and percussive force |

| Common Applications | Removing bearings, bushings, and gears | Extracting axles, shafts, and dents |

| Advantages | Minimizes damage with precise control | Effective for stubborn parts with high force |

| Disadvantages | Slower; requires proper setup | Higher risk of damage if misused |

| Typical Materials | Steel construction with adjustable arms | Heavy-duty steel shaft with sliding weight |

Introduction to Puller Tools and Slide Hammers

Puller tools and slide hammers are essential devices used in mechanical repair for removing tightly fitted parts such as bearings, gears, and pulleys. Puller tools typically consist of jaws and a central screw that applies force to extract components without causing damage, making them ideal for precision tasks. Slide hammers utilize a weighted hammer that slides along a shaft to deliver impact force, offering a robust solution for dislodging stubborn or heavily seated parts.

Key Differences Between Puller Tools and Slide Hammers

Puller tools use mechanical advantage through arms or jaws to grip and extract parts like bearings or gears, offering controlled application of force. Slide hammers generate impact force by sliding a heavy weight along a shaft to deliver sudden, strong pulls ideal for stubborn or stuck components. Pullers provide precision and minimize surface damage, while slide hammers excel in extracting parts where leverage alone is insufficient.

How Puller Tools Work in Car Repair

Puller tools work in car repair by applying controlled force to remove components such as gears, bearings, and pulleys without causing damage. They typically use mechanical advantage through threaded rods, arms, or claws that grip the part securely, allowing gradual extraction from the shaft or housing. This precise method reduces the risk of damage to surrounding parts compared to slide hammers, which rely on impact force for component removal.

Using a Slide Hammer: Applications and Techniques

Using a slide hammer is essential for removing tightly fitted parts such as bearings, gears, and shafts in automotive and machinery repair. The tool operates by delivering controlled impact force through a weighted hammer that slides along the shaft, allowing technicians to dislodge components without causing damage. Proper technique involves securing the slide hammer to the part, ensuring steady, straight pulls to prevent bending or warping of the surrounding structures.

Pros and Cons of Puller Tools

Puller tools offer precision and control in removing gears, bearings, and pulleys without causing damage to surrounding components, making them ideal for delicate or intricately assembled parts. Their primary advantage is the ability to apply controlled, even force, reducing the risk of distortion or breakage compared to the more forceful impact of slide hammers. However, puller tools can be slower and less effective on severely rusted or tightly fit components where the aggressive impact of a slide hammer might be necessary to break free stuck parts.

Advantages and Disadvantages of Slide Hammers

Slide hammers excel in delivering controlled impact force to extract tightly fitted parts, making them ideal for removing bearings, gears, and shafts without causing damage. Their disadvantages include potential operator fatigue due to repetitive manual force and limited precision compared to hydraulic pullers, which may result in less control over extraction speed and direction. Slide hammers also require clear access around the part being removed, restricting their use in confined or obstructed spaces.

When to Use a Puller Tool vs Slide Hammer

Puller tools are ideal for removing gears, bearings, and pulleys with minimal surface damage and precise control in tight spaces. Slide hammers excel at extracting components like dents, axle shafts, and stuck parts where impact force is necessary to dislodge firmly seated items. Choosing between them depends on the repair task's sensitivity and the need for controlled pulling versus brute force impact.

Safety Tips for Using Puller Tools and Slide Hammers

When using puller tools and slide hammers, always wear safety goggles and gloves to protect against flying debris and sharp edges. Ensure the puller or slide hammer is securely attached to the object to prevent unexpected release or slippage during operation. Regularly inspect the tools for wear or damage, and use the correct size and type of tool to match the specific repair task to minimize injury risk.

Maintenance and Care for Puller Tools and Slide Hammers

Proper maintenance of puller tools and slide hammers is essential to ensure their longevity and effectiveness in repair tasks. Regular cleaning of metal surfaces, lubrication of moving parts, and inspection for wear or damage prevent rust and mechanical failure. Storing these tools in a dry, organized environment reduces corrosion risk and facilitates quick access during maintenance operations.

Choosing the Right Tool for Your Car Repair Needs

Selecting between a puller tool and a slide hammer depends on the specific repair task and vehicle type, as puller tools excel in removing bearings, gears, and pulleys with precise force, while slide hammers are ideal for extracting stubborn components like dents or stuck parts. Understanding vehicle make, part accessibility, and the required force application ensures optimal tool performance and prevents further damage during disassembly. Investing in high-quality, compatible tools enhances repair efficiency, reduces labor time, and maintains the integrity of automotive components.

Puller Tool vs Slide Hammer Infographic

cardiffo.com

cardiffo.com