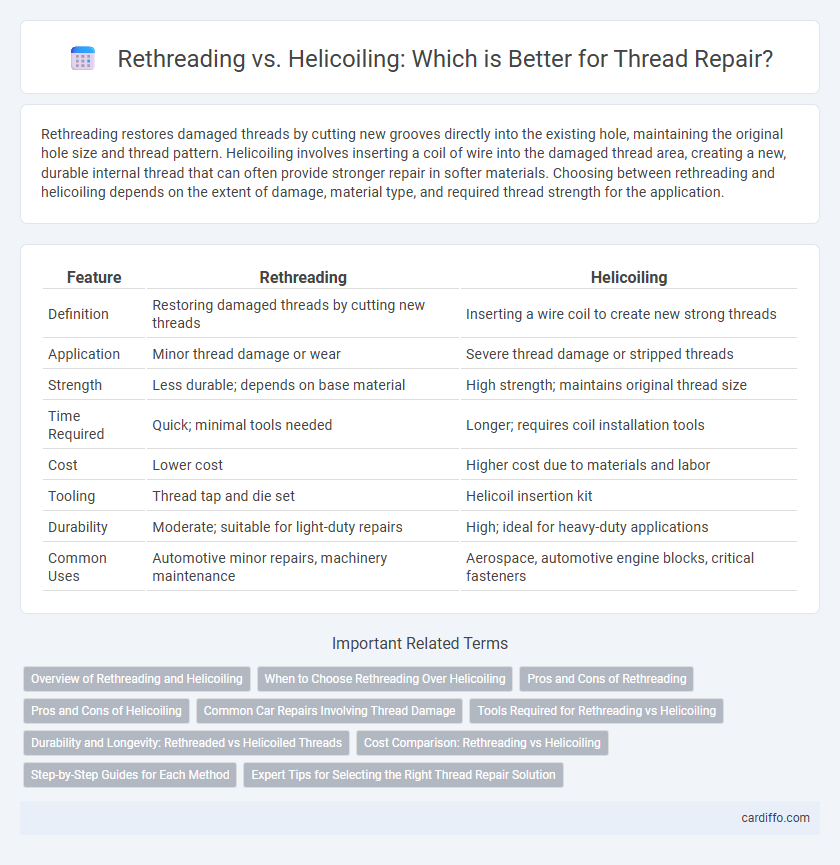

Rethreading restores damaged threads by cutting new grooves directly into the existing hole, maintaining the original hole size and thread pattern. Helicoiling involves inserting a coil of wire into the damaged thread area, creating a new, durable internal thread that can often provide stronger repair in softer materials. Choosing between rethreading and helicoiling depends on the extent of damage, material type, and required thread strength for the application.

Table of Comparison

| Feature | Rethreading | Helicoiling |

|---|---|---|

| Definition | Restoring damaged threads by cutting new threads | Inserting a wire coil to create new strong threads |

| Application | Minor thread damage or wear | Severe thread damage or stripped threads |

| Strength | Less durable; depends on base material | High strength; maintains original thread size |

| Time Required | Quick; minimal tools needed | Longer; requires coil installation tools |

| Cost | Lower cost | Higher cost due to materials and labor |

| Tooling | Thread tap and die set | Helicoil insertion kit |

| Durability | Moderate; suitable for light-duty repairs | High; ideal for heavy-duty applications |

| Common Uses | Automotive minor repairs, machinery maintenance | Aerospace, automotive engine blocks, critical fasteners |

Overview of Rethreading and Helicoiling

Rethreading involves restoring damaged screw threads by cutting new grooves directly into the original hole, preserving the original diameter but requiring precise alignment and intact base material. Helicoiling inserts a coiled wire thread into the stripped or damaged hole, creating a durable, wear-resistant internal thread often stronger than the original metal. This technique is preferred for repairing high-stress components or soft metals where thread integrity and load distribution are critical.

When to Choose Rethreading Over Helicoiling

Rethreading is ideal when the existing hole is only slightly damaged or when the material thickness allows for a full new thread to be cut without compromising strength. It maintains the original thread size and is often faster and more cost-effective than helicoiling, which involves inserting a coil thread repair. Choose rethreading when the thread damage is minimal and the structural integrity of the workpiece must be preserved without the added complexity of an insert.

Pros and Cons of Rethreading

Rethreading restores damaged threads by cutting new ones directly into the existing hole, offering a cost-effective and quick solution with minimal material removal. This method maintains the original hole size but may weaken the thread's strength if the damage is extensive or the material is soft. However, rethreading is less suitable for severely stripped threads, where heliocoiling provides a more durable and reinforced repair by inserting a coiled wire thread.

Pros and Cons of Helicoiling

Helicoiling offers a reliable method for repairing stripped or damaged threads by inserting a durable coil that restores the original thread size and strength, making it ideal for high-stress applications. The coils resist corrosion and wear, extending the lifespan of the repair, but installation requires precise hole preparation and the correct coil size to avoid improper fit or reduced thread integrity. While more cost-effective and less invasive compared to rethreading or replacing parts, helicoiling may not be suitable for severely damaged or oversized holes where structural restoration is critical.

Common Car Repairs Involving Thread Damage

Common car repairs involving thread damage often require rethreading or helicoiling to restore the integrity of stripped or worn bolt holes. Rethreading involves cutting new threads directly into the damaged hole, suitable for minor wear, while helicoiling inserts a durable coil thread insert to reinforce severely damaged or oversized holes. Choosing between rethreading and helicoiling depends on the extent of thread damage and the need for long-lasting repair in critical engine or suspension components.

Tools Required for Rethreading vs Helicoiling

Rethreading requires basic tools including a tap and die set, wrench, and cutting oil to restore damaged threads by cutting new grooves. Helicoiling involves specialized tools such as a helicoil insertion tool, thread tap specific to helicoil inserts, and coil inserts made from stainless steel to reinforce the threaded hole. The helicoil method demands more precise equipment and preparation compared to the simpler and more manual process of rethreading.

Durability and Longevity: Rethreaded vs Helicoiled Threads

Rethreaded threads restore the original thread profile by cutting new threads, which maintains the metal's structural integrity and offers moderate durability for less stressed applications. Helicoiled threads insert a coiled wire thread insert, providing enhanced strength and resistance to wear, corrosion, and fatigue, making them more suitable for high-stress or frequently repaired holes. The longevity of helicoiled threads typically surpasses rethreaded ones due to their ability to distribute loads more evenly and resist deformation over time.

Cost Comparison: Rethreading vs Helicoiling

Rethreading typically costs less than helicoiling due to its simpler process and fewer materials required. Helicoiling involves inserting a threaded coil, which increases labor time and material expenses, making it pricier. Choosing between the two depends on the damage severity and long-term durability needs, with rethreading being more cost-effective for minor repairs.

Step-by-Step Guides for Each Method

Rethreading involves cleaning and restoring the original thread by using a thread file or a die, starting with removing debris and carefully realigning the threads to their initial profile. Helicoiling requires drilling out the damaged thread, tapping a new thread to fit the coil insert, and then inserting a helicoil spring to create a durable, reinforced thread inside the damaged hole. Both methods demand precise measurements and proper tools, with rethreading best suited for minor damage and helicoiling ideal for reinforcing severely stripped threads.

Expert Tips for Selecting the Right Thread Repair Solution

When selecting the right thread repair solution, consider the extent of thread damage and the application load; rethreading works well for minor wear, while helicoiling offers superior strength for stripped or damaged holes. Use appropriate thread gauges and torque specifications to ensure proper installation and durability. Experts recommend helicoils for high-stress environments where original thread integrity is compromised.

rethreading vs helicoiling Infographic

cardiffo.com

cardiffo.com