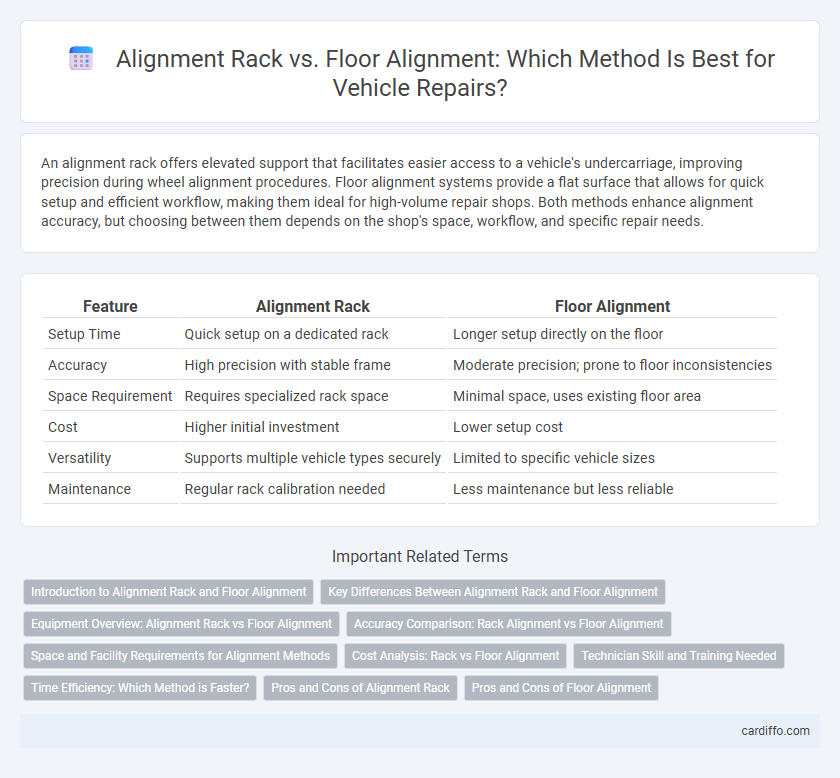

An alignment rack offers elevated support that facilitates easier access to a vehicle's undercarriage, improving precision during wheel alignment procedures. Floor alignment systems provide a flat surface that allows for quick setup and efficient workflow, making them ideal for high-volume repair shops. Both methods enhance alignment accuracy, but choosing between them depends on the shop's space, workflow, and specific repair needs.

Table of Comparison

| Feature | Alignment Rack | Floor Alignment |

|---|---|---|

| Setup Time | Quick setup on a dedicated rack | Longer setup directly on the floor |

| Accuracy | High precision with stable frame | Moderate precision; prone to floor inconsistencies |

| Space Requirement | Requires specialized rack space | Minimal space, uses existing floor area |

| Cost | Higher initial investment | Lower setup cost |

| Versatility | Supports multiple vehicle types securely | Limited to specific vehicle sizes |

| Maintenance | Regular rack calibration needed | Less maintenance but less reliable |

Introduction to Alignment Rack and Floor Alignment

Alignment racks provide a stable platform for precise wheel alignment by securely lifting the vehicle, ensuring accurate adjustments for optimal tire performance and safety. Floor alignment systems, integrated directly into the workshop floor, offer a space-saving solution with advanced sensors for real-time measurements and quicker service times. Both technologies enhance alignment accuracy but differ in installation complexity and operational workflow.

Key Differences Between Alignment Rack and Floor Alignment

Alignment racks provide a stable, elevated platform for precise vehicle measurements and adjustments, enhancing accuracy and accessibility during repairs. Floor alignment systems are directly installed on the service bay floor, offering a more space-efficient solution but potentially less stability in heavy-duty applications. The key differences lie in installation method, space utilization, and the level of measurement precision achievable.

Equipment Overview: Alignment Rack vs Floor Alignment

Alignment racks provide a robust, elevated platform designed for precise vehicle positioning and suspension adjustments, typically featuring built-in gauges and locking mechanisms for enhanced accuracy. Floor alignment systems utilize portable sensors and computerized equipment directly on the workshop floor, offering flexibility and quick setup for diverse vehicle types and alignment needs. Both systems integrate advanced laser or camera technology, but alignment racks excel in stability and comprehensive diagnostics, while floor alignment emphasizes mobility and space efficiency.

Accuracy Comparison: Rack Alignment vs Floor Alignment

Rack alignment systems offer higher accuracy for vehicle wheel alignment due to their stabilized platform and integrated sensors, minimizing measurement errors caused by uneven surfaces. Floor alignment methods, while more flexible and cost-effective, often face challenges with floor irregularities and less precise sensor calibration, leading to slight deviations in alignment readings. Precision in rack alignment ensures optimal vehicle handling and tire wear, making it the preferred choice for critical repair tasks requiring exact alignment angles.

Space and Facility Requirements for Alignment Methods

Alignment racks demand elevated setups with substantial vertical clearance, often requiring dedicated bays to accommodate their frameworks and hydraulic systems. Floor alignment systems, by contrast, are compact, sitting flush with the ground and needing minimal overhead space, making them ideal for facilities with low ceilings or limited vertical room. Space efficiency in floor alignment translates to easier integration into existing workshops without extensive structural modifications.

Cost Analysis: Rack vs Floor Alignment

Rack alignment systems typically involve higher initial investment due to specialized frames and mounting hardware, but they offer improved accuracy and faster setup times, reducing labor costs over time. Floor alignment setups may have lower upfront costs but often require more extensive space and additional manual adjustments, leading to increased labor expenses and longer downtime. Analyzing total cost of ownership reveals that rack alignment can be more cost-effective for high-volume repair shops seeking precision and efficiency.

Technician Skill and Training Needed

Alignment racks require technicians to have advanced training in precision measurement and the use of specialized equipment to ensure accurate wheel alignment. Floor alignment, while less dependent on costly machinery, demands technicians possess strong manual skills and comprehensive knowledge of vehicle suspension systems for effective results. Both methods necessitate ongoing education to keep pace with evolving automotive technologies and alignment standards.

Time Efficiency: Which Method is Faster?

Alignment racks offer a structured and elevated platform that significantly reduces time spent on setup and adjustments, enhancing overall efficiency. Floor alignment requires additional preparation and precise positioning, often prolonging the alignment process due to limited accessibility and maneuverability. Consequently, alignment racks are generally faster, streamlining workflow and minimizing downtime in automotive repair.

Pros and Cons of Alignment Rack

Alignment racks offer enhanced stability and precision by securely elevating the vehicle, enabling technicians to perform accurate wheel alignment inspections and adjustments. They provide greater accessibility to vehicle suspension components compared to floor alignment systems but require more space and typically involve higher installation and maintenance costs. While alignment racks improve accuracy and efficiency, floor alignment setups are more cost-effective and space-saving, making the rack ideal for high-volume or specialized repair shops.

Pros and Cons of Floor Alignment

Floor alignment offers enhanced precision and stability by securely anchoring the vehicle during the repair process, reducing measurement errors common with traditional alignment racks. It enables easier access to the vehicle's underside for comprehensive inspections and adjustments, yet it typically requires a larger shop space and higher initial investment compared to portable alignment racks. However, floor alignment's durability and ability to accommodate various vehicle sizes make it a preferred choice for high-volume repair shops seeking consistent alignment accuracy.

Alignment Rack vs Floor Alignment Infographic

cardiffo.com

cardiffo.com