Resurfacing a cylinder head involves machining the surface to restore a flat, smooth finish, which can correct warping and ensure proper sealing without the need for a full replacement. Cylinder head replacement is necessary when the head is severely cracked, damaged, or warped beyond repair, providing a brand-new or remanufactured part for optimal engine performance. Choosing resurfacing over replacement can save time and costs while maintaining engine integrity when the damage is minimal.

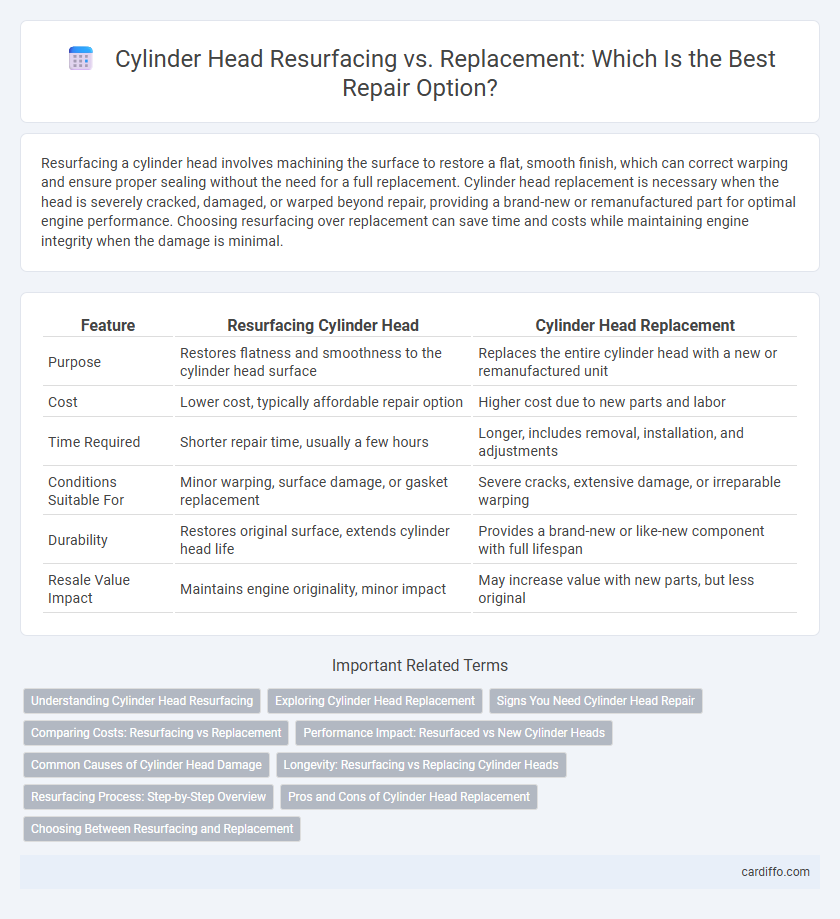

Table of Comparison

| Feature | Resurfacing Cylinder Head | Cylinder Head Replacement |

|---|---|---|

| Purpose | Restores flatness and smoothness to the cylinder head surface | Replaces the entire cylinder head with a new or remanufactured unit |

| Cost | Lower cost, typically affordable repair option | Higher cost due to new parts and labor |

| Time Required | Shorter repair time, usually a few hours | Longer, includes removal, installation, and adjustments |

| Conditions Suitable For | Minor warping, surface damage, or gasket replacement | Severe cracks, extensive damage, or irreparable warping |

| Durability | Restores original surface, extends cylinder head life | Provides a brand-new or like-new component with full lifespan |

| Resale Value Impact | Maintains engine originality, minor impact | May increase value with new parts, but less original |

Understanding Cylinder Head Resurfacing

Cylinder head resurfacing restores the flatness and smoothness of the cylinder head surface to ensure a proper seal with the head gasket, which prevents leaks and maintains engine compression. This repair is typically chosen when the cylinder head has minor warping or surface damage but remains structurally sound, avoiding the cost and complexity of full cylinder head replacement. Precision machining tools measure and remove a thin layer of metal from the head, preserving engine performance and extending the component's service life.

Exploring Cylinder Head Replacement

Cylinder head replacement is often necessary when the head is severely cracked, warped beyond repair, or has extensive damage that resurfacing cannot fix. New cylinder heads restore engine compression and prevent coolant or oil leaks, ensuring optimal engine performance and reliability. This replacement process is usually more expensive but provides a long-term solution compared to resurfacing, which is suitable for minor surface imperfections.

Signs You Need Cylinder Head Repair

Persistent engine overheating, white smoke from the exhaust, and coolant contamination in the oil indicate cylinder head damage requiring repair or resurfacing. Visible cracks, warped surfaces, or damaged valve seats on the cylinder head surface often necessitate resurfacing to restore a proper seal and engine performance. In severe cases of extensive corrosion or fractures, cylinder head replacement becomes the only viable solution to prevent further engine damage.

Comparing Costs: Resurfacing vs Replacement

Resurfacing a cylinder head typically costs between $100 and $250, significantly less than cylinder head replacement, which can range from $1,000 to $3,000 or more depending on the make and model of the vehicle. Resurfacing extends the life of the existing cylinder head by correcting warping or minor damage, making it a cost-effective option for moderate wear. Replacement involves buying a new or remanufactured cylinder head, covering extensive damage or cracks, but incurs higher parts and labor expenses.

Performance Impact: Resurfaced vs New Cylinder Heads

Resurfacing a cylinder head restores a smooth, flat sealing surface, improving compression and preventing leaks, which can enhance engine performance without the cost of replacement. New cylinder heads provide completely fresh components, ensuring maximum durability and optimal heat dissipation, often resulting in superior long-term performance. However, resurfaced heads may retain microscopic imperfections or warpage, potentially limiting performance compared to factory-new heads in high-stress or high-performance applications.

Common Causes of Cylinder Head Damage

Common causes of cylinder head damage include overheating due to coolant leaks or malfunctioning thermostats, which can cause warping and cracking. Corrosion from improper coolant maintenance and poor sealing of the head gasket can also lead to damage. Frequent exposure to high combustion pressures and pre-ignition can exacerbate wear, making resurfacing or replacement necessary.

Longevity: Resurfacing vs Replacing Cylinder Heads

Resurfacing a cylinder head restores the flatness and smoothness of its surface, extending its lifespan by ensuring proper sealing and preventing engine leaks, often suitable for minor warping or damage. Cylinder head replacement involves installing a brand-new or refurbished head, offering a longer-term solution especially when the head has severe cracks or structural damage that resurfacing cannot fix. Choosing resurfacing over replacement typically provides a cost-effective longevity boost, but replacement guarantees extended durability and improved engine performance in cases of significant wear.

Resurfacing Process: Step-by-Step Overview

Resurfacing a cylinder head involves precise machining to restore a flat, smooth surface, ensuring proper sealing with the engine block. The process begins with removing the cylinder head from the engine, followed by cleaning to eliminate carbon deposits and debris. Using a milling machine or grinder, the surface is carefully leveled and smoothed before reinstallation, optimizing engine performance and preventing leaks.

Pros and Cons of Cylinder Head Replacement

Cylinder head replacement ensures a completely new or remanufactured head, eliminating any pre-existing cracks, warping, or corrosion, which reduces the risk of future engine failures and provides reliable long-term performance. However, this option typically involves higher costs and longer labor time compared to resurfacing, as it requires removal, installation, and potential adjustments to components like valves and gaskets. Replacement is ideal for extensively damaged or cracked cylinder heads, while resurfacing suits minor warping or surface imperfections.

Choosing Between Resurfacing and Replacement

Choosing between resurfacing a cylinder head and replacing it depends on the head's structural integrity and extent of damage. Resurfacing is ideal for heads with minor warping or surface corrosion, restoring a flat sealing surface while retaining the original component. Replacement is necessary when cracks, severe warping, or extensive corrosion compromise the cylinder head's durability and performance.

Resurfacing cylinder head vs cylinder head replacement Infographic

cardiffo.com

cardiffo.com