A torque wrench provides precise control over the amount of torque applied to a fastener, ensuring accurate tightening and preventing damage. An impact wrench delivers high torque output with rapid rotational impacts, making it ideal for loosening stubborn or rusted bolts quickly. Choosing between them depends on the need for precision versus speed in repair tasks.

Table of Comparison

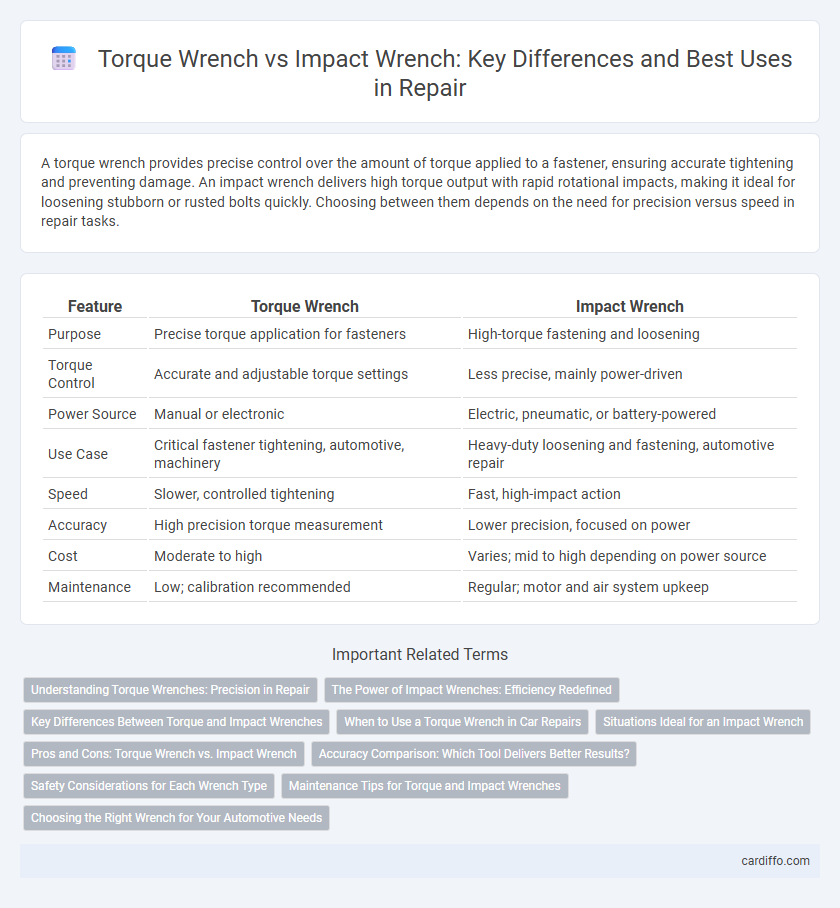

| Feature | Torque Wrench | Impact Wrench |

|---|---|---|

| Purpose | Precise torque application for fasteners | High-torque fastening and loosening |

| Torque Control | Accurate and adjustable torque settings | Less precise, mainly power-driven |

| Power Source | Manual or electronic | Electric, pneumatic, or battery-powered |

| Use Case | Critical fastener tightening, automotive, machinery | Heavy-duty loosening and fastening, automotive repair |

| Speed | Slower, controlled tightening | Fast, high-impact action |

| Accuracy | High precision torque measurement | Lower precision, focused on power |

| Cost | Moderate to high | Varies; mid to high depending on power source |

| Maintenance | Low; calibration recommended | Regular; motor and air system upkeep |

Understanding Torque Wrenches: Precision in Repair

Torque wrenches deliver precise, controlled torque essential for tightening bolts to specific manufacturer specifications, preventing over-tightening or damage during repairs. These tools are calibrated to ensure consistent, accurate force application, which is critical in automotive, machinery, and mechanical repairs where exact torque settings maintain safety and functionality. Understanding torque wrenches enhances repair quality by ensuring fasteners are securely tightened while preserving structural integrity.

The Power of Impact Wrenches: Efficiency Redefined

Impact wrenches deliver unparalleled torque, enabling rapid loosening and tightening of stubborn fasteners with minimal effort compared to traditional torque wrenches. Designed for high-torque applications, impact wrenches combine rotational force with concussive blows, drastically reducing job times in automotive repair and heavy machinery maintenance. Their efficiency redefines power tool performance, especially in environments demanding speed and consistent force output.

Key Differences Between Torque and Impact Wrenches

Torque wrenches provide precise control over the amount of torque applied to fasteners, ensuring accurate tightening to manufacturer specifications, which is critical in automotive and machinery repairs. Impact wrenches deliver high rotational force through rapid, repeated impacts, making them ideal for loosening or tightening stubborn or rusted bolts quickly but without fine torque accuracy. The key difference lies in torque accuracy and application: torque wrenches are used where exact torque values are essential, while impact wrenches prioritize speed and power over precision.

When to Use a Torque Wrench in Car Repairs

Use a torque wrench in car repairs when precise tightening of bolts or nuts is essential to manufacturer specifications, such as lug nuts, cylinder head bolts, and suspension components. This tool ensures accurate torque application to prevent over-tightening or under-tightening, which can cause mechanical failures or safety issues. Torque wrenches are critical during engine assembly, brake system repairs, and when working with delicate parts requiring exact torque settings.

Situations Ideal for an Impact Wrench

Impact wrenches deliver high torque and rapid rotational force, making them ideal for loosening stubborn bolts, automotive repairs, and heavy machinery maintenance where speed and power are critical. Their pneumatic or electric designs excel in repetitive tasks requiring consistent torque without operator fatigue. Impact wrenches outperform torque wrenches in scenarios demanding quick fastener removal or installation under high resistance.

Pros and Cons: Torque Wrench vs. Impact Wrench

Torque wrenches provide precise control over tightening torque, reducing the risk of over-tightening or damaging fasteners, making them ideal for automotive and mechanical repairs requiring accuracy. Impact wrenches deliver high torque output rapidly, significantly speeding up loosening or tightening tasks, especially useful for heavy-duty applications but can cause over-torquing or fastener damage without careful control. Choosing between a torque wrench and an impact wrench depends on the need for precision versus speed and power in repair work.

Accuracy Comparison: Which Tool Delivers Better Results?

A torque wrench provides superior accuracy in applying precise torque values, essential for critical automotive and machinery repairs where exact bolt tension prevents damage or failure. Impact wrenches offer high torque output and speed but lack precise control, making them ideal for quickly loosening or tightening fasteners without specific torque requirements. For tasks requiring consistent and accurate torque measurements, torque wrenches deliver better results by minimizing the risk of over- or under-tightening.

Safety Considerations for Each Wrench Type

Torque wrenches offer precise control over bolt tension, reducing the risk of over-tightening and ensuring safe assembly in critical applications. Impact wrenches deliver high torque rapidly but require caution to prevent damage to fasteners and injury from sudden torque spikes. Always follow manufacturer guidelines and wear appropriate protective equipment to maximize safety with both wrench types.

Maintenance Tips for Torque and Impact Wrenches

Regular calibration is essential to maintain the accuracy of torque wrenches, preventing over-tightening or under-tightening that can damage fasteners and equipment. Impact wrenches require periodic inspection of the air motor or battery, along with lubrication of moving parts to ensure optimal performance and prevent premature wear. Storing both torque and impact wrenches in a clean, dry environment helps avoid corrosion and mechanical failure, extending the lifespan of the tools.

Choosing the Right Wrench for Your Automotive Needs

Torque wrenches provide precise control over the amount of torque applied to fasteners, essential for tightening lug nuts and engine components to manufacturer specifications. Impact wrenches deliver high torque quickly, ideal for loosening stubborn bolts and heavy-duty repairs but can easily overtighten if not monitored carefully. Selecting the right wrench depends on the task: use torque wrenches for accuracy and impact wrenches for speed and power in automotive repair.

Torque wrench vs impact wrench Infographic

cardiffo.com

cardiffo.com