TIG welding offers superior precision and control, making it ideal for thin materials and intricate repairs, while MIG welding excels in faster, more straightforward applications on thicker metals. TIG provides cleaner welds with minimal spatter, which reduces post-weld cleanup, whereas MIG is preferred for its ease of use and efficiency in large-scale repair projects. Selecting between TIG and MIG welding depends on factors such as material thickness, project complexity, and required weld quality.

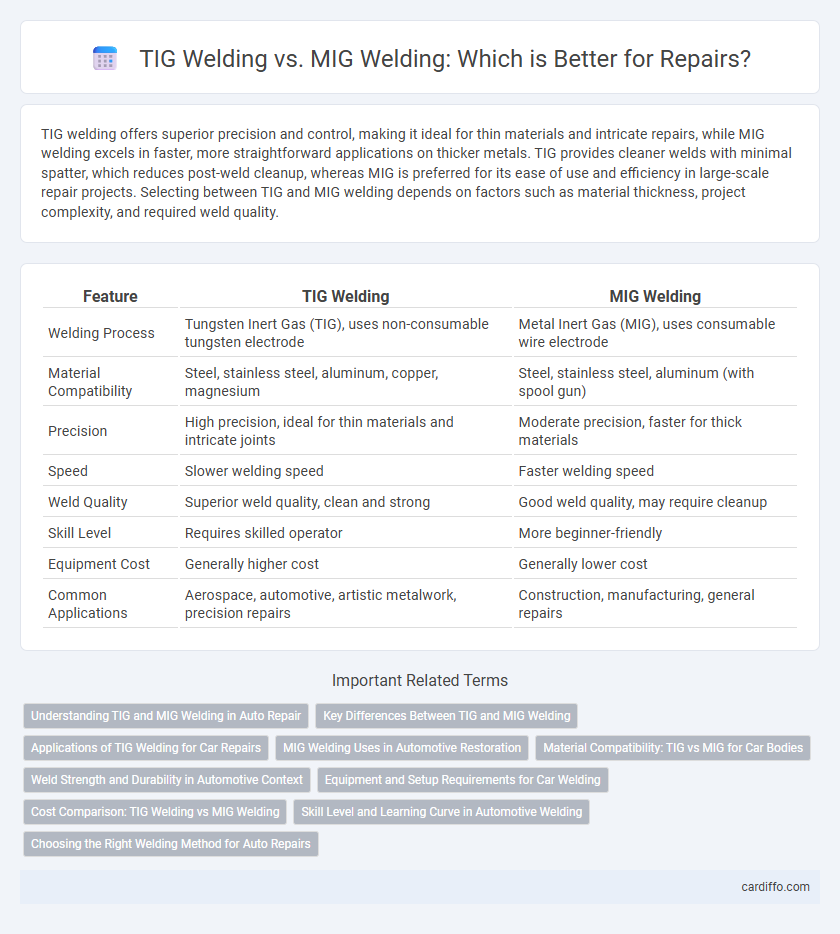

Table of Comparison

| Feature | TIG Welding | MIG Welding |

|---|---|---|

| Welding Process | Tungsten Inert Gas (TIG), uses non-consumable tungsten electrode | Metal Inert Gas (MIG), uses consumable wire electrode |

| Material Compatibility | Steel, stainless steel, aluminum, copper, magnesium | Steel, stainless steel, aluminum (with spool gun) |

| Precision | High precision, ideal for thin materials and intricate joints | Moderate precision, faster for thick materials |

| Speed | Slower welding speed | Faster welding speed |

| Weld Quality | Superior weld quality, clean and strong | Good weld quality, may require cleanup |

| Skill Level | Requires skilled operator | More beginner-friendly |

| Equipment Cost | Generally higher cost | Generally lower cost |

| Common Applications | Aerospace, automotive, artistic metalwork, precision repairs | Construction, manufacturing, general repairs |

Understanding TIG and MIG Welding in Auto Repair

TIG welding offers precise, high-quality welds ideal for thin metals and detailed auto repair tasks, while MIG welding provides faster, more versatile welds suitable for thicker materials and large repair jobs. Auto repair professionals prefer TIG welding for stainless steel and aluminum components due to its superior control and clean finish, whereas MIG welding is favored for structural repairs on body panels and frames. Understanding the strengths of TIG and MIG welding enhances repair efficiency and ensures durable, reliable vehicle restoration.

Key Differences Between TIG and MIG Welding

TIG welding offers precise control and is ideal for thin materials, producing clean welds with minimal spatter, whereas MIG welding provides faster deposition rates suitable for thicker metals and larger projects. TIG uses a non-consumable tungsten electrode and requires a separate filler material, while MIG employs a continuously fed consumable wire electrode that doubles as filler. The shielding gas in TIG is typically pure argon, delivering superior weld quality, compared to the argon/CO2 mix commonly used in MIG for cost-efficiency and versatility.

Applications of TIG Welding for Car Repairs

TIG welding is ideal for car repairs requiring precise, clean welds on thin metals like aluminum and stainless steel, commonly found in vehicle frames and exhaust systems. Its ability to produce high-quality, corrosion-resistant joints makes it preferred for intricate body work and custom modifications where durability and appearance are critical. TIG welding's control over heat input also minimizes warping, preserving the integrity of delicate automotive parts during repair.

MIG Welding Uses in Automotive Restoration

MIG welding is widely preferred in automotive restoration due to its ease of use, faster welding speed, and ability to handle thin metals common in vehicle bodies. This welding technique provides clean, strong welds ideal for repairing rusted panels, frames, and chassis components without excessive heat distortion. MIG welding's versatility with various metal types and thicknesses makes it a staple in restoring classic cars and modern vehicles efficiently.

Material Compatibility: TIG vs MIG for Car Bodies

TIG welding offers superior precision and is ideal for thin or exotic metals like aluminum and stainless steel commonly found in car bodies, ensuring minimal distortion and strong, clean welds. MIG welding excels with thicker steel panels due to its faster welding speed and ease of use, making it efficient for large repairs on standard automotive sheet metal. Selecting TIG or MIG depends on the specific car body material and repair requirements, balancing weld quality and production speed.

Weld Strength and Durability in Automotive Context

TIG welding produces welds with superior strength and durability due to its precise heat control and clean, high-quality weld beads, making it ideal for critical automotive repairs on thin metals and high-stress components. MIG welding offers faster weld speeds and ease of use, but its welds typically exhibit slightly lower strength and may require more post-weld cleaning in automotive applications. For structural automotive repairs demanding maximum weld integrity, TIG welding is often preferred to ensure long-lasting performance under dynamic stress conditions.

Equipment and Setup Requirements for Car Welding

TIG welding equipment for car repair involves a torch with a non-consumable tungsten electrode and requires a separate filler rod, demanding a precise gas flow regulator and clean shielding gas such as argon. MIG welding uses a continuously fed consumable wire electrode through a welding gun, paired with a gas supply system commonly utilizing a mix of argon and CO2 for shielding, making setup faster and simpler for automotive sheet metal work. For car welding, MIG's equipment is often preferred in productivity settings due to its ease of use and faster setup, while TIG offers superior control and precision, ideal for detailed or thin metal repairs.

Cost Comparison: TIG Welding vs MIG Welding

TIG welding typically incurs higher costs due to slower processing speeds and increased labor time compared to MIG welding, which is faster and more suitable for high-volume production. Equipment expenses for TIG machines are generally steeper, including precision-controlled power supplies and specialized torch components, while MIG welding systems offer more affordable and versatile setups. Consumables such as tungsten electrodes for TIG add to operating costs, whereas MIG welding uses less expensive wire feed materials, making MIG welding more cost-effective for large-scale repair projects.

Skill Level and Learning Curve in Automotive Welding

TIG welding in automotive repair requires a higher skill level and has a steeper learning curve compared to MIG welding due to its precise control over heat and filler material. MIG welding is generally easier to master, making it ideal for beginners and quick repairs on thin automotive metals. Professionals often prefer TIG welding for complex repairs demanding superior weld quality and appearance despite the extended training needed.

Choosing the Right Welding Method for Auto Repairs

TIG welding offers precise control and produces clean, high-quality welds ideal for thin metals and detailed auto body repairs, while MIG welding provides faster, more efficient welds suited for thicker materials and large-scale frame work. Selecting the right welding method depends on factors such as metal thickness, repair complexity, and desired finish quality to ensure durable and reliable vehicle restoration. Considering equipment availability and operator skill levels also plays a crucial role in achieving optimal results in automotive repair projects.

TIG welding vs MIG welding Infographic

cardiffo.com

cardiffo.com