Clip repair offers a quicker and less invasive solution by replacing damaged clips without altering the original metal structure. Weld repair involves fusing metal parts together, providing a stronger and more permanent fix but requires more time and skill to execute properly. Choosing between clip repair and weld repair depends on the extent of damage, desired durability, and the specific area of the vehicle or equipment being serviced.

Table of Comparison

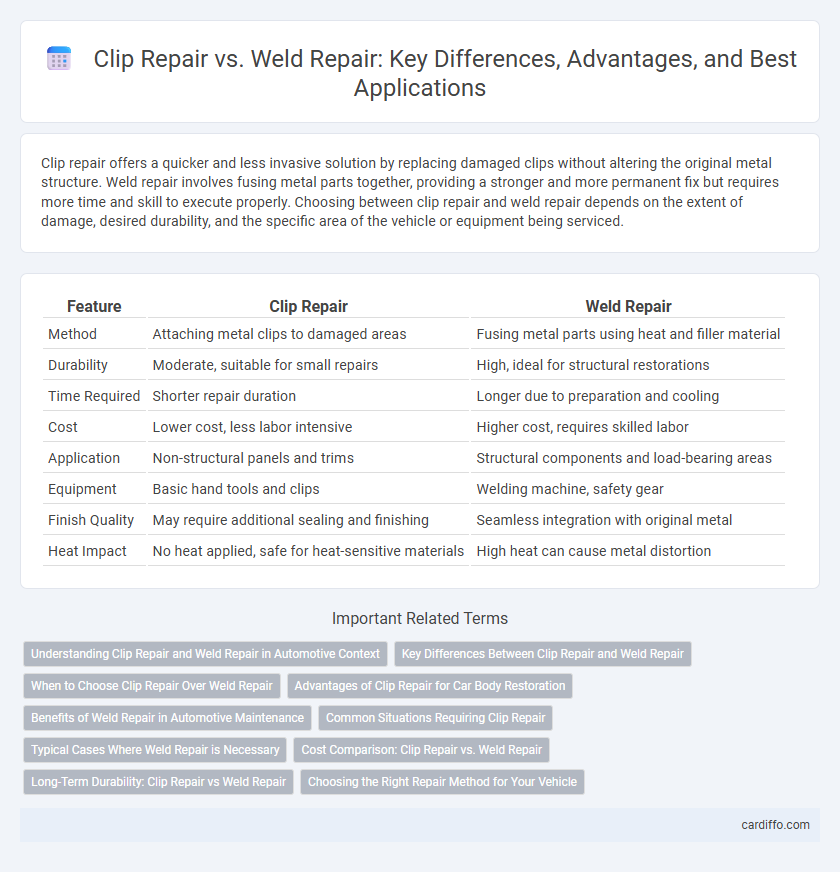

| Feature | Clip Repair | Weld Repair |

|---|---|---|

| Method | Attaching metal clips to damaged areas | Fusing metal parts using heat and filler material |

| Durability | Moderate, suitable for small repairs | High, ideal for structural restorations |

| Time Required | Shorter repair duration | Longer due to preparation and cooling |

| Cost | Lower cost, less labor intensive | Higher cost, requires skilled labor |

| Application | Non-structural panels and trims | Structural components and load-bearing areas |

| Equipment | Basic hand tools and clips | Welding machine, safety gear |

| Finish Quality | May require additional sealing and finishing | Seamless integration with original metal |

| Heat Impact | No heat applied, safe for heat-sensitive materials | High heat can cause metal distortion |

Understanding Clip Repair and Weld Repair in Automotive Context

Clip repair in automotive applications involves replacing damaged plastic or metal clips that secure panels and trim, offering a quick and cost-effective solution without altering the original material structure. Weld repair focuses on rejoining metal parts by melting and fusing the base materials, providing a durable and strong bond essential for structural integrity in collision-damaged vehicles. Choosing between clip repair and weld repair depends on the location and type of damage, with clips suited for non-structural attachments and welds necessary for critical frame and body repairs.

Key Differences Between Clip Repair and Weld Repair

Clip repair involves attaching replacement parts using mechanical fasteners or adhesive clips, offering quicker installation and less heat distortion compared to weld repair. Weld repair fuses materials together by melting base metals at high temperatures, creating a permanent bond that provides greater structural integrity and strength. Clip repair is typically used for minor, non-structural damage, whereas weld repair is preferred for critical, load-bearing components requiring durability and longevity.

When to Choose Clip Repair Over Weld Repair

Clip repair is ideal when preserving base material integrity is crucial, such as in thin metals or components prone to heat distortion. This method allows for quicker, less invasive repairs without the risks associated with high temperatures in weld repair. Choose clip repair when speed, minimal thermal impact, and maintaining original metal properties are priorities.

Advantages of Clip Repair for Car Body Restoration

Clip repair offers significant advantages for car body restoration by minimizing heat exposure, which reduces the risk of metal warping and paint damage compared to weld repair. This method enables faster installation and removal, preserving the original structural integrity and factory fitment of the vehicle's panels. Using clips also limits the need for extensive refinishing, resulting in lower labor costs and shorter repair times.

Benefits of Weld Repair in Automotive Maintenance

Weld repair in automotive maintenance provides superior strength and durability compared to clip repair, ensuring structural integrity under stress and impact. It allows for precise restoration of damaged metal parts, preventing further corrosion and extending the vehicle's lifespan. This method also offers a seamless finish that maintains the vehicle's original design and safety standards.

Common Situations Requiring Clip Repair

Common situations requiring clip repair include damaged or broken clips on automotive panels, interior trim, and exterior moldings due to impacts, wear, or stress fractures. Clip repair is preferred when the surrounding material remains intact and structural integrity is not compromised, allowing for a quick and cost-effective fix. Weld repair is typically reserved for cases with significant metal distortion or cracks where clips alone cannot restore proper attachment.

Typical Cases Where Weld Repair is Necessary

Weld repair is necessary in cases involving severe structural damage, such as cracks in load-bearing metal components or corrosion-induced fractures where clips cannot restore integrity. It provides a permanent bond crucial for high-stress areas subject to heavy loads or thermal expansion. Unlike clip repair, weld repair is essential for ensuring safety and durability in automotive frames, industrial machinery, and pipeline systems.

Cost Comparison: Clip Repair vs. Weld Repair

Clip repair generally offers a lower upfront cost compared to weld repair due to reduced labor time and minimal specialized equipment requirements. Weld repair involves higher expenses driven by skilled labor, welding materials, and quality control measures, but it often results in a more durable and permanent fix. Cost efficiency of clip repair is favorable for minor damages, whereas weld repair justifies its investment in scenarios demanding long-term structural integrity.

Long-Term Durability: Clip Repair vs Weld Repair

Clip repair offers easier installation and reduced heat impact on surrounding materials, but weld repair provides superior long-term durability by creating a stronger, more permanent bond that resists stress and environmental factors. Welding ensures enhanced structural integrity and longevity, especially in high-stress applications, whereas clips may loosen or degrade over time under continuous load or exposure. Choosing weld repair is often advisable when long-term strength and durability are critical for safety and performance.

Choosing the Right Repair Method for Your Vehicle

Clip repair preserves the original metal and is ideal for minor damage, minimizing the risk of compromising structural integrity. Weld repair offers a stronger, more permanent fix suitable for severe damage but requires skilled labor to ensure safety and durability. Selecting the appropriate method depends on the extent of damage, vehicle type, and long-term repair goals.

Clip repair vs Weld repair Infographic

cardiffo.com

cardiffo.com