A compression test measures the pressure generated in a cylinder during the engine's compression stroke to assess the condition of piston rings, valves, and head gasket. A leak-down test quantifies the rate at which air escapes from the cylinder, pinpointing specific issues like valve leaks, worn piston rings, or head gasket failures by introducing compressed air. Both tests provide valuable insights into engine health, but the leak-down test offers a more detailed diagnosis of internal engine leaks.

Table of Comparison

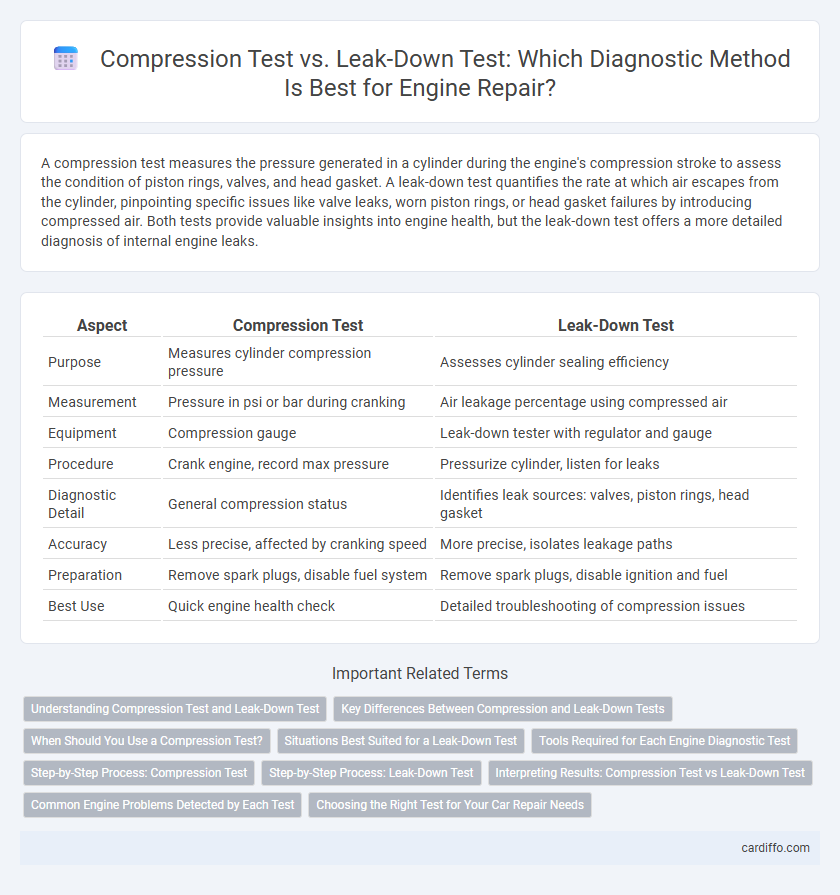

| Aspect | Compression Test | Leak-Down Test |

|---|---|---|

| Purpose | Measures cylinder compression pressure | Assesses cylinder sealing efficiency |

| Measurement | Pressure in psi or bar during cranking | Air leakage percentage using compressed air |

| Equipment | Compression gauge | Leak-down tester with regulator and gauge |

| Procedure | Crank engine, record max pressure | Pressurize cylinder, listen for leaks |

| Diagnostic Detail | General compression status | Identifies leak sources: valves, piston rings, head gasket |

| Accuracy | Less precise, affected by cranking speed | More precise, isolates leakage paths |

| Preparation | Remove spark plugs, disable fuel system | Remove spark plugs, disable ignition and fuel |

| Best Use | Quick engine health check | Detailed troubleshooting of compression issues |

Understanding Compression Test and Leak-Down Test

Compression tests measure the pressure generated by the engine cylinders during the combustion cycle to assess the sealing efficiency of piston rings, valves, and head gasket. Leak-down tests involve introducing compressed air into the cylinder and measuring the rate of leakage to pinpoint specific failures in the combustion chamber components. Both tests provide critical diagnostic data for evaluating engine health and identifying sources of power loss.

Key Differences Between Compression and Leak-Down Tests

Compression tests measure the maximum pressure generated by each cylinder during the engine's compression stroke, providing a quick snapshot of overall cylinder health and piston ring sealing. Leak-down tests quantify the rate of air leakage from the cylinder at a set pressure, pinpointing specific issues such as valve leaks, head gasket failure, or piston ring wear. The key difference lies in compression tests assessing peak pressure uniformly, while leak-down tests offer more detailed diagnostics by measuring how much pressure escapes under controlled conditions.

When Should You Use a Compression Test?

Use a compression test when diagnosing engine performance issues such as misfires, rough idling, or poor fuel efficiency to measure the pressure within each cylinder during the compression stroke. This test helps identify problems like worn piston rings, damaged valves, or head gasket failures by providing a quick assessment of cylinder sealing. Compression tests are ideal for initial troubleshooting before proceeding to more detailed diagnostics like leak-down tests.

Situations Best Suited for a Leak-Down Test

A leak-down test is best suited for diagnosing engine issues in situations where pinpointing the exact location of leaks within the combustion chamber is critical, such as identifying valve seat leaks, head gasket failures, or cracked cylinder walls. This test provides detailed insights by measuring the percentage of air loss under controlled conditions, making it ideal for engines exhibiting symptoms like rough idling, low power, or poor compression without clear cause from a compression test. Mechanics prefer leak-down tests during detailed engine overhauls or troubleshooting persistent performance problems to ensure precise repair strategies.

Tools Required for Each Engine Diagnostic Test

A compression test requires a compression gauge, adapter specific to the engine's spark plug hole, and a hand-operated or pneumatic wrench to crank the engine; this simple setup measures cylinder pressure to assess piston ring and valve seal integrity. A leak-down test involves a leak-down tester, an air compressor, and fittings to connect the equipment to the cylinder, enabling precise detection of leaks through valves, piston rings, or head gaskets by measuring air pressure loss. While the compression test gauges are generally more affordable and portable, the leak-down test tools provide detailed diagnostics but require more specialized equipment and setup complexity.

Step-by-Step Process: Compression Test

The compression test begins by disabling the ignition system and fuel supply to prevent engine start during the procedure. Next, remove all spark plugs and insert a compression gauge into the first cylinder's spark plug hole. Crank the engine several times while monitoring the gauge, then record the pressure reading and repeat the process for each cylinder to assess engine compression integrity.

Step-by-Step Process: Leak-Down Test

The leak-down test begins by removing the spark plug from the cylinder to be tested and positioning the piston at top dead center on the compression stroke. Next, compressed air is introduced into the cylinder through a leak-down tester, which measures the percentage of air loss to identify leaks in the valves, piston rings, or head gasket. The resulting data helps diagnose specific engine issues by analyzing the rate and location of air escaping from the combustion chamber.

Interpreting Results: Compression Test vs Leak-Down Test

Interpreting results from a compression test involves measuring the maximum cylinder pressure during the engine's compression stroke to identify potential issues such as worn piston rings or valves, with ideal values typically above 120 psi per cylinder. A leak-down test measures the percentage of air escaping from the cylinder when compressed air is introduced, providing a more detailed diagnosis by pinpointing the source of leakage, such as intake valves, exhaust valves, or head gaskets, usually with acceptable leakage below 10%. Compression tests offer a quick overall health check while leak-down tests give specific insights into the integrity of the combustion chamber components.

Common Engine Problems Detected by Each Test

Compression tests reveal common engine problems such as worn piston rings, damaged cylinder walls, and leaking valves by measuring the pressure each cylinder generates during the combustion cycle. Leak-down tests identify issues like blown head gaskets, cracked cylinder heads, and valve seat leaks by pressurizing the cylinder and measuring the rate of air leakage. Both tests are essential for diagnosing combustion efficiency and pinpointing specific engine wear or damage.

Choosing the Right Test for Your Car Repair Needs

Selecting between a compression test and a leak-down test depends on the specific diagnosis required for engine performance issues. A compression test quickly measures cylinder pressure to identify overall engine health and detect problems like worn piston rings or valves. In contrast, a leak-down test provides a more detailed analysis by measuring the rate at which air escapes from a cylinder, pinpointing precise locations of leaks such as head gasket failures or valve seat problems.

Compression Test vs Leak-Down Test Infographic

cardiffo.com

cardiffo.com