Block sealer provides a protective layer that prevents moisture and contaminants from penetrating the damaged surface, extending the lifespan of repairs without altering the structure. Physical repair involves mechanically fixing the damaged area through methods such as patching, welding, or replacing parts to restore full functionality. Choosing between block sealer and physical repair depends on the severity of the damage and the need for structural integrity versus surface protection.

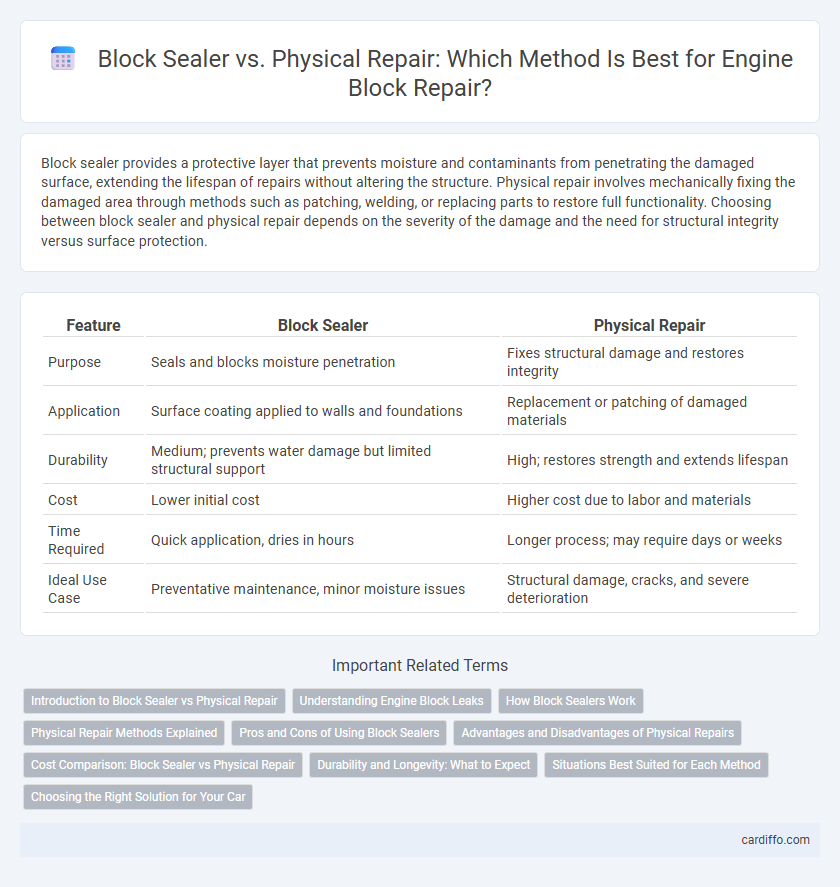

Table of Comparison

| Feature | Block Sealer | Physical Repair |

|---|---|---|

| Purpose | Seals and blocks moisture penetration | Fixes structural damage and restores integrity |

| Application | Surface coating applied to walls and foundations | Replacement or patching of damaged materials |

| Durability | Medium; prevents water damage but limited structural support | High; restores strength and extends lifespan |

| Cost | Lower initial cost | Higher cost due to labor and materials |

| Time Required | Quick application, dries in hours | Longer process; may require days or weeks |

| Ideal Use Case | Preventative maintenance, minor moisture issues | Structural damage, cracks, and severe deterioration |

Introduction to Block Sealer vs Physical Repair

Block sealer is a cost-effective solution designed to temporarily seal cracks and holes in concrete or masonry surfaces, preventing water ingress and further deterioration. Physical repair involves the complete restoration of the damaged area through methods such as patching, resurfacing, or replacing the affected sections to restore structural integrity. Choosing between block sealer and physical repair depends on the extent of damage, with block sealer suited for minor surface defects and physical repair necessary for significant structural issues.

Understanding Engine Block Leaks

Engine block leaks often result from cracks or porous surfaces that allow coolant or oil to escape, compromising engine performance and causing overheating or contamination. Block sealers offer a chemical solution that temporarily seals small cracks and leaks by filling microscopic gaps, providing a quick and cost-effective repair without disassembly. Physical repair involves welding, machining, or replacing damaged sections of the engine block, offering a permanent and reliable fix but requiring more time, expertise, and expense.

How Block Sealers Work

Block sealers penetrate porous surfaces by filling micro-cracks with specialized polymers that harden to create a waterproof and airtight barrier. This process prevents moisture, chemicals, and contaminants from infiltrating the material, effectively halting further deterioration. Unlike physical repair, block sealing addresses damage at a microscopic level, enhancing longevity without altering the structural integrity.

Physical Repair Methods Explained

Physical repair methods involve directly restoring damaged surfaces by removing defects, filling cracks with epoxy or polymer-based compounds, and resurfacing areas for structural integrity. Unlike block sealers that primarily provide protective coatings to prevent moisture ingress and corrosion, physical repairs address the root cause by rebuilding the material's original strength. Techniques such as grinding, patching, and abrasive blasting ensure the repaired section meets durability and safety standards.

Pros and Cons of Using Block Sealers

Block sealers provide a protective barrier that prevents moisture penetration and enhances the durability of masonry surfaces, reducing the need for frequent repairs. They are cost-effective and easy to apply but may not address structural damage or cracks, which require physical repair methods for long-term stability. Using block sealers as a preventive measure prolongs surface life but relying solely on them can lead to overlooking underlying issues that physical repairs effectively resolve.

Advantages and Disadvantages of Physical Repairs

Physical repairs provide a permanent solution by directly addressing structural damage, ensuring restored functionality and durability. However, they often require more time, specialized skills, and higher costs compared to block sealers. The process may involve material replacement or reassembly, potentially causing extended downtime and more complex logistics.

Cost Comparison: Block Sealer vs Physical Repair

Block sealer treatments typically cost between $50 and $150 per application, offering a more affordable solution for minor cracks and surface damage compared to physical repairs. Physical repairs, such as patching or replacement, often range from $300 to over $1,000 depending on the extent of the damage and materials required. Choosing block sealer can significantly reduce upfront expenses while physical repair provides a longer-lasting fix but at a higher cost.

Durability and Longevity: What to Expect

Block sealers provide a protective barrier against moisture and environmental damage, enhancing the durability of masonry surfaces by preventing cracks and erosion over time. Physical repairs address existing damage by restoring structural integrity, offering immediate strength but may require future maintenance if underlying moisture issues persist. For long-term longevity, combining block sealing with physical repair ensures comprehensive protection and sustained durability of the repaired structure.

Situations Best Suited for Each Method

Block sealer is best suited for preventing moisture infiltration and minor surface cracks in concrete structures, offering a cost-effective, non-invasive solution ideal for maintenance and early-stage damage control. Physical repair methods, such as patching or structural replacement, are necessary for addressing significant deterioration, large cracks, or compromised load-bearing capacity requiring durable restoration. Choosing between block sealer and physical repair depends on the extent of damage and the need for long-term structural integrity in repair projects.

Choosing the Right Solution for Your Car

Block sealer offers a cost-effective option for minor leaks and surface crack repairs, sealing without extensive labor. Physical repair involves replacing or machining damaged components, providing a long-term fix especially for severe engine block damage. Selecting the right solution depends on the severity of the damage, vehicle value, and expected lifespan of the repair.

Block sealer vs physical repair Infographic

cardiffo.com

cardiffo.com