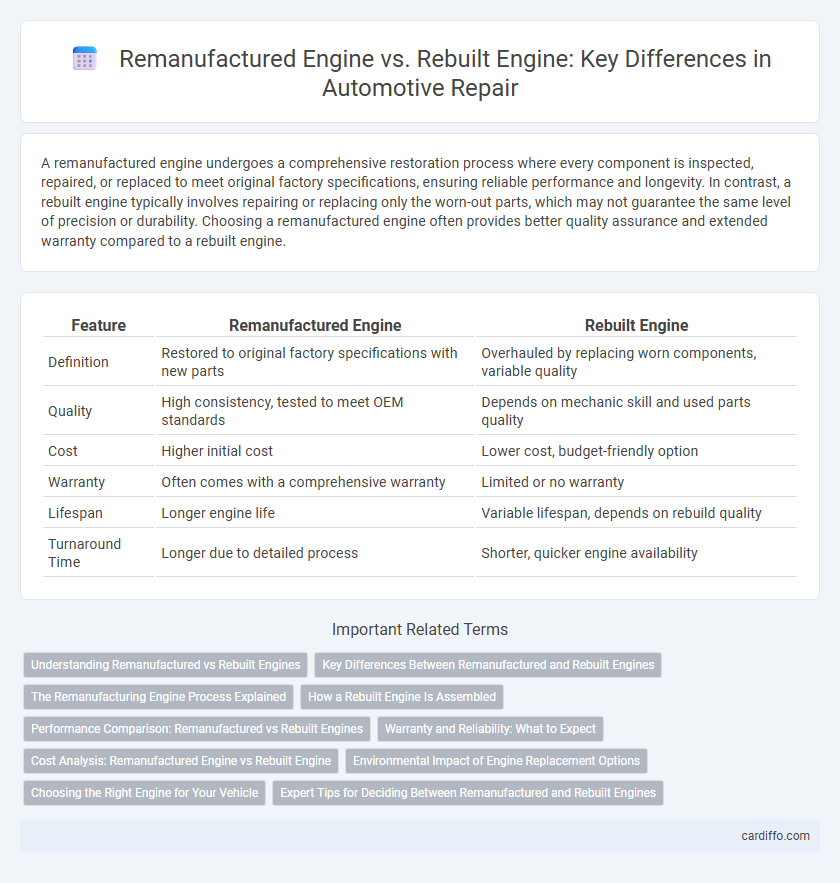

A remanufactured engine undergoes a comprehensive restoration process where every component is inspected, repaired, or replaced to meet original factory specifications, ensuring reliable performance and longevity. In contrast, a rebuilt engine typically involves repairing or replacing only the worn-out parts, which may not guarantee the same level of precision or durability. Choosing a remanufactured engine often provides better quality assurance and extended warranty compared to a rebuilt engine.

Table of Comparison

| Feature | Remanufactured Engine | Rebuilt Engine |

|---|---|---|

| Definition | Restored to original factory specifications with new parts | Overhauled by replacing worn components, variable quality |

| Quality | High consistency, tested to meet OEM standards | Depends on mechanic skill and used parts quality |

| Cost | Higher initial cost | Lower cost, budget-friendly option |

| Warranty | Often comes with a comprehensive warranty | Limited or no warranty |

| Lifespan | Longer engine life | Variable lifespan, depends on rebuild quality |

| Turnaround Time | Longer due to detailed process | Shorter, quicker engine availability |

Understanding Remanufactured vs Rebuilt Engines

Remanufactured engines undergo a comprehensive restoration process where all components are replaced or machined to meet original factory specifications, ensuring like-new performance and extended warranty coverage. Rebuilt engines are repaired using existing parts that are cleaned, machined, and replaced as needed, often resulting in varying quality depending on the extent of wear and mechanic expertise. Understanding the difference helps vehicle owners make informed decisions based on budget, reliability, and long-term engine performance expectations.

Key Differences Between Remanufactured and Rebuilt Engines

Remanufactured engines undergo a thorough factory-level restoration using new parts to meet original specifications, ensuring high reliability and performance. Rebuilt engines are repaired by replacing only worn components, often using a mix of new and used parts, which may result in variable quality and lifespan. The key differences lie in the extent of restoration, quality control standards, and warranty coverage, with remanufactured engines generally offering a more consistent and longer-lasting solution.

The Remanufacturing Engine Process Explained

The remanufacturing engine process involves completely disassembling the engine, thoroughly cleaning all components, and inspecting parts to meet original equipment manufacturer (OEM) specifications. Worn or damaged components are either replaced with new parts or restored to like-new condition, ensuring enhanced durability and performance. This process surpasses standard rebuilding by adhering to strict quality control measures, resulting in engines with longer lifespans and improved reliability.

How a Rebuilt Engine Is Assembled

A rebuilt engine is assembled by carefully disassembling the original engine, thoroughly cleaning each component, and inspecting parts for wear or damage before replacing only the faulty or worn-out components. Precision machining is performed on key parts such as the cylinder head, block, and crankshaft to restore them to original factory specifications. The engine is then reassembled with new gaskets, seals, bearings, and piston rings, ensuring optimized performance and reliability comparable to a new engine.

Performance Comparison: Remanufactured vs Rebuilt Engines

Remanufactured engines undergo a comprehensive overhaul with new parts and precise factory specifications, resulting in performance and reliability that often matches or exceeds that of a brand-new engine. Rebuilt engines are repaired using a combination of new and reused components, which can vary in quality, potentially leading to less consistent performance and longevity. Performance differences between remanufactured and rebuilt engines often depend on the extent of the overhaul, with remanufactured units typically offering superior durability, fuel efficiency, and power output.

Warranty and Reliability: What to Expect

Remanufactured engines typically come with a manufacturer-backed warranty, offering coverage that matches or exceeds the original engine warranty, ensuring higher reliability and peace of mind. Rebuilt engines often carry limited warranties, usually from the repair shop, which may vary in duration and coverage, reflecting the variability in component replacement and workmanship. Expect remanufactured engines to provide greater long-term reliability due to strict quality control and standardized processes compared to rebuilt engines.

Cost Analysis: Remanufactured Engine vs Rebuilt Engine

Remanufactured engines generally come at a higher upfront cost due to comprehensive factory refurbishment and warranty coverage, which reduces long-term expenses and increases reliability. Rebuilt engines typically have a lower initial price but may incur more frequent maintenance and repairs, affecting overall cost-effectiveness. Comparing total ownership expenses, remanufactured engines often provide better value through enhanced durability and fewer unexpected breakdowns.

Environmental Impact of Engine Replacement Options

Remanufactured engines offer a significantly lower environmental impact compared to rebuilt engines due to the extensive reuse of components and reduced waste generation. The remanufacturing process conserves raw materials and lowers energy consumption by restoring engines to like-new condition using high-quality parts and precise manufacturing standards. In contrast, rebuilt engines often involve replacing fewer components, leading to more frequent replacements and higher cumulative resource usage over time.

Choosing the Right Engine for Your Vehicle

Choosing the right engine for your vehicle involves understanding the distinctions between remanufactured and rebuilt engines. Remanufactured engines are restored to factory specifications with new components and undergo rigorous testing for reliability, making them ideal for long-term performance. Rebuilt engines, often repaired with reused parts, can be cost-effective but may vary in quality and longevity depending on the extent of the repair work.

Expert Tips for Deciding Between Remanufactured and Rebuilt Engines

Choosing between remanufactured and rebuilt engines depends on factors like budget, engine condition, and desired longevity; remanufactured engines undergo complete disassembly and replacement of worn parts, ensuring near-new performance. Rebuilt engines typically involve repairing or replacing only damaged components, making them more cost-effective but potentially less reliable. Experts recommend evaluating warranty coverage, vehicle usage, and compatibility with the specific engine model to make an informed decision.

Remanufactured engine vs Rebuilt engine Infographic

cardiffo.com

cardiffo.com