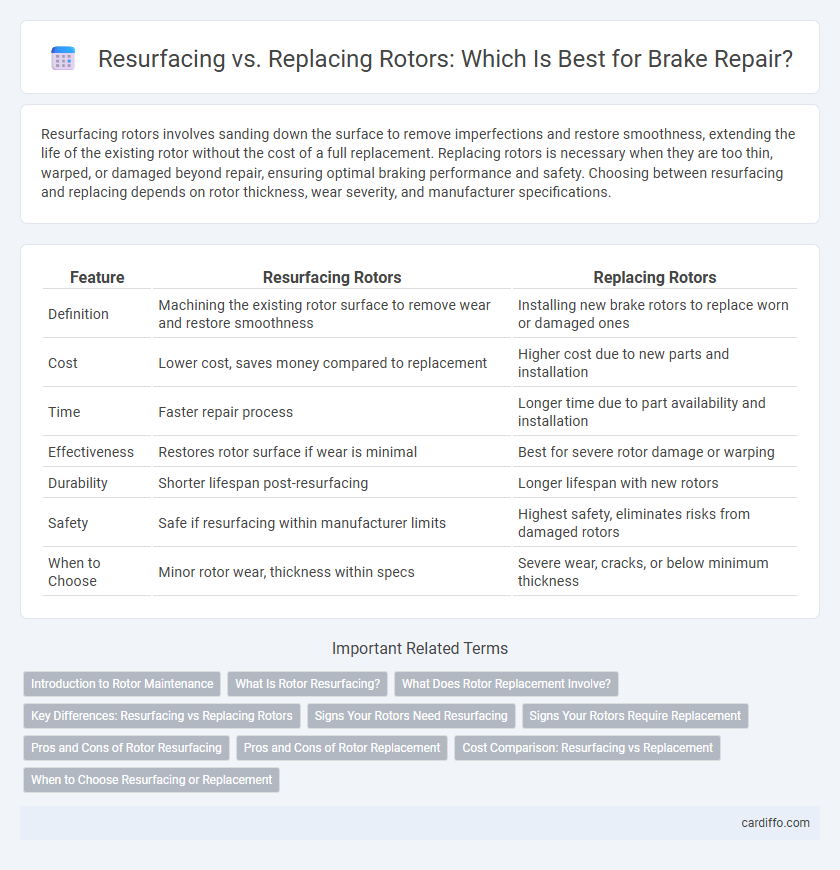

Resurfacing rotors involves sanding down the surface to remove imperfections and restore smoothness, extending the life of the existing rotor without the cost of a full replacement. Replacing rotors is necessary when they are too thin, warped, or damaged beyond repair, ensuring optimal braking performance and safety. Choosing between resurfacing and replacing depends on rotor thickness, wear severity, and manufacturer specifications.

Table of Comparison

| Feature | Resurfacing Rotors | Replacing Rotors |

|---|---|---|

| Definition | Machining the existing rotor surface to remove wear and restore smoothness | Installing new brake rotors to replace worn or damaged ones |

| Cost | Lower cost, saves money compared to replacement | Higher cost due to new parts and installation |

| Time | Faster repair process | Longer time due to part availability and installation |

| Effectiveness | Restores rotor surface if wear is minimal | Best for severe rotor damage or warping |

| Durability | Shorter lifespan post-resurfacing | Longer lifespan with new rotors |

| Safety | Safe if resurfacing within manufacturer limits | Highest safety, eliminates risks from damaged rotors |

| When to Choose | Minor rotor wear, thickness within specs | Severe wear, cracks, or below minimum thickness |

Introduction to Rotor Maintenance

Rotor maintenance is essential for ensuring optimal braking performance and vehicle safety. Resurfacing rotors involves machining the surface to restore smoothness, which can extend rotor life and improve contact with brake pads. Replacing rotors is recommended when they are warped, excessively worn, or below minimum thickness, preventing issues like brake pulsation and reduced stopping power.

What Is Rotor Resurfacing?

Rotor resurfacing is the process of removing a thin layer of the brake rotor's surface to eliminate imperfections such as warping, scoring, or uneven wear, restoring a smooth and flat surface for optimal brake pad contact. This procedure extends the rotor's lifespan by addressing minor damage without the need for full replacement, while maintaining proper braking performance. Resurfacing is typically performed when rotor thickness remains within manufacturer specifications, ensuring safety and reliability in braking systems.

What Does Rotor Replacement Involve?

Rotor replacement involves removing the worn brake rotors and installing new ones to restore optimal braking performance. This process includes detaching the wheel, caliper, and old rotor, then securing the new rotor before reassembling the braking components. Proper rotor replacement ensures smoother braking, reduces vibration, and prevents excessive brake pad wear.

Key Differences: Resurfacing vs Replacing Rotors

Resurfacing rotors involves machining the existing brake disc to restore a smooth, even surface, extending rotor life and saving costs when thickness remains above the minimum specification. Replacing rotors is necessary when the discs are warped, cracked, or worn below safety limits, ensuring optimal braking performance and safety. The key differences hinge on disk condition, cost-effectiveness, and the vehicle's braking requirements.

Signs Your Rotors Need Resurfacing

Worn or grooved brake rotors often produce a pulsating brake pedal or vibrating steering wheel during braking, signaling the need for resurfacing. Visible scoring, heat spots, or excessive rotor thickness variation measured with a micrometer are clear indicators that rotors require resurfacing to restore smooth braking performance. When rotors exceed manufacturer-specified minimum thickness or show uneven wear patterns, resurfacing is recommended to prevent brake system damage and maintain safety standards.

Signs Your Rotors Require Replacement

Worn or warped rotors often cause vibration or pulsation in the brake pedal, signaling the need for replacement. Deep grooves, cracks, or significant rust on the rotor surface reduce braking efficiency and safety. If rotor thickness falls below the manufacturer's minimum specification, resurfacing is insufficient and full replacement is required.

Pros and Cons of Rotor Resurfacing

Rotor resurfacing restores the brake surface by removing minor wear and imperfections, extending rotor life and saving costs compared to full replacement. It may reduce rotor thickness, potentially leading to overheating and warping if done repeatedly or on severely worn rotors. Resurfacing is ideal for rotors with minimal damage but less effective on rotors with deep grooves, cracks, or significant wear requiring replacement.

Pros and Cons of Rotor Replacement

Rotor replacement ensures optimal braking performance by eliminating issues like warping or deep grooves that resurfacing cannot fully correct. New rotors provide improved heat dissipation and structural integrity, reducing the risk of brake fade and enhancing safety. However, replacement costs are higher compared to resurfacing, and discarding usable rotors may increase environmental waste.

Cost Comparison: Resurfacing vs Replacement

Resurfacing rotors typically costs between $30 and $50 per rotor, offering a budget-friendly option that restores surface smoothness and extends rotor life. Replacement rotors, however, average $75 to $150 each, with premium or performance rotors reaching higher prices, representing a more substantial investment but guaranteeing optimal braking performance. Choosing between resurfacing and replacement depends on rotor thickness, wear severity, and long-term cost-effectiveness in brake maintenance.

When to Choose Resurfacing or Replacement

Resurfacing rotors is ideal when the brake rotors have minor surface imperfections or slight warping, allowing for a smooth, flat surface to restore optimal braking performance while saving costs. Replacement is necessary if the rotors are below the minimum thickness specification, have deep grooves, cracks, or severe warping that compromise safety and braking efficiency. Always measure rotor thickness and inspect for damage before deciding between resurfacing or replacement to ensure reliable and safe brake operation.

Resurfacing vs replacing rotors Infographic

cardiffo.com

cardiffo.com