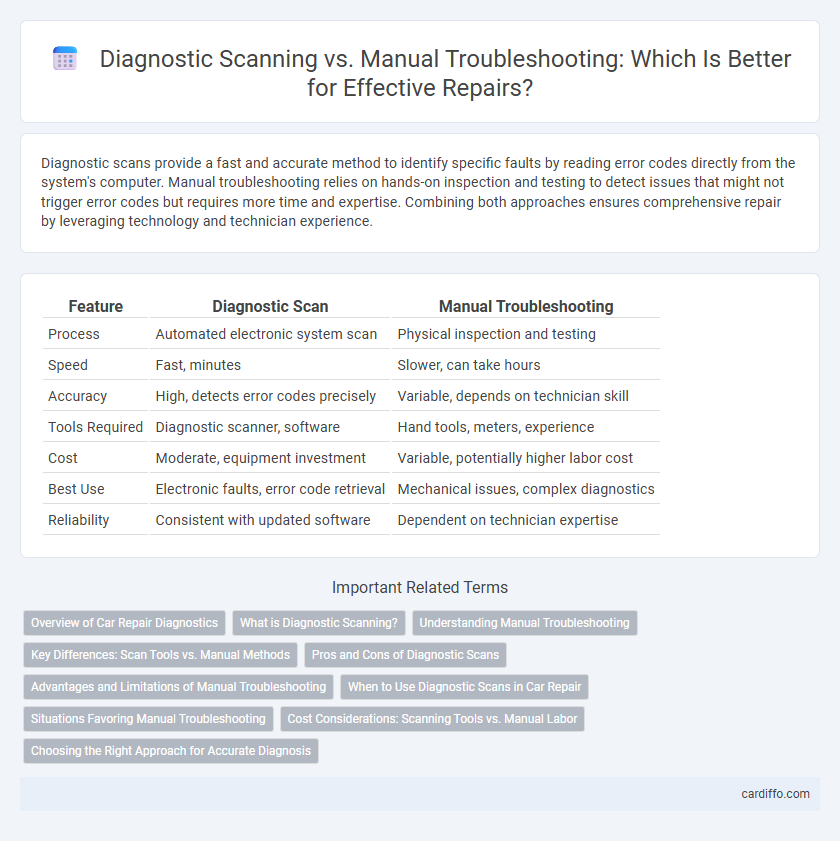

Diagnostic scans provide a fast and accurate method to identify specific faults by reading error codes directly from the system's computer. Manual troubleshooting relies on hands-on inspection and testing to detect issues that might not trigger error codes but requires more time and expertise. Combining both approaches ensures comprehensive repair by leveraging technology and technician experience.

Table of Comparison

| Feature | Diagnostic Scan | Manual Troubleshooting |

|---|---|---|

| Process | Automated electronic system scan | Physical inspection and testing |

| Speed | Fast, minutes | Slower, can take hours |

| Accuracy | High, detects error codes precisely | Variable, depends on technician skill |

| Tools Required | Diagnostic scanner, software | Hand tools, meters, experience |

| Cost | Moderate, equipment investment | Variable, potentially higher labor cost |

| Best Use | Electronic faults, error code retrieval | Mechanical issues, complex diagnostics |

| Reliability | Consistent with updated software | Dependent on technician expertise |

Overview of Car Repair Diagnostics

Diagnostic scans utilize advanced onboard vehicle computer systems to quickly identify fault codes and system malfunctions, offering precise data for efficient car repair diagnostics. Manual troubleshooting relies on a technician's expertise to interpret symptoms and physical signs, which can be time-consuming but valuable for identifying issues not detected by scans. Combining both methods enhances repair accuracy by leveraging technology and skilled observation in automotive diagnostics.

What is Diagnostic Scanning?

Diagnostic scanning involves using computerized tools and software to quickly identify error codes and system malfunctions in vehicles or electronic devices. Unlike manual troubleshooting, which relies on visual inspection and experience, diagnostic scanning provides precise fault detection by accessing onboard diagnostic systems (OBD) and real-time data streams. This technology enhances repair accuracy and reduces diagnosis time by pinpointing specific issues based on stored diagnostic trouble codes (DTCs).

Understanding Manual Troubleshooting

Manual troubleshooting involves a detailed, hands-on approach where technicians use experience and observational skills to identify the root cause of a problem. This method relies heavily on interpreting symptoms and testing components individually, which can uncover issues that diagnostic scans might miss. Understanding manual troubleshooting enhances the ability to diagnose complex repair scenarios where automated tools provide limited information, ensuring more accurate and effective repairs.

Key Differences: Scan Tools vs. Manual Methods

Diagnostic scan tools provide precise error codes and real-time data from vehicle computer systems, enabling quicker identification of faults compared to manual troubleshooting. Manual methods rely on technician experience and physical inspection, which can be time-consuming and subject to human error but are essential for diagnosing complex or intermittent issues not detected by scans. Scan tools offer systematic diagnostics through OBD-II data retrieval, while manual troubleshooting requires detailed knowledge of vehicle components and wiring for effective problem resolution.

Pros and Cons of Diagnostic Scans

Diagnostic scans rapidly identify error codes and system malfunctions, increasing repair accuracy and saving time compared to manual troubleshooting. They may require specialized equipment and can sometimes miss intermittent or mechanical issues that only manual inspection can detect. While diagnostic scans enhance precision and efficiency, they should be complemented with hands-on assessment for comprehensive repairs.

Advantages and Limitations of Manual Troubleshooting

Manual troubleshooting offers the advantage of hands-on, detailed inspection that can identify complex issues beyond the scope of diagnostic scans, such as intermittent electrical faults or physically damaged components. It allows technicians to use experience and intuition, enabling tailored problem-solving when diagnostic tools yield ambiguous or no error codes. However, manual troubleshooting is time-consuming, dependent on technician skill, and may miss subtle digital errors easily flagged by automated diagnostic scans.

When to Use Diagnostic Scans in Car Repair

Diagnostic scans are essential when electronic systems malfunction or error codes appear, enabling technicians to quickly identify specific issues within complex vehicle components. Use diagnostic scans during routine maintenance to detect hidden problems early, preventing costly repairs and ensuring optimal engine performance. Manual troubleshooting remains valuable for hands-on inspections and addressing non-electronic issues that scanners may not detect.

Situations Favoring Manual Troubleshooting

Manual troubleshooting excels in situations with complex mechanical failures where sensor data may be inadequate or misleading, such as intermittent electrical issues or physical damage not detected by diagnostics. It is particularly effective when a technician's experience and intuition are essential to interpret anomalies that automated scans cannot identify. Hands-on inspection and physical testing provide critical insights during repairs of vintage vehicles or customized machinery lacking advanced onboard diagnostics.

Cost Considerations: Scanning Tools vs. Manual Labor

Diagnostic scans often reduce overall repair costs by quickly identifying issues, minimizing labor hours and diagnostic guesswork. While advanced scanning tools require an upfront investment, the efficiency and precision they offer typically lower long-term expenses compared to manual troubleshooting. Manual labor involves higher variability in time and skill, often increasing repair costs due to prolonged diagnostics and potential misdiagnosis.

Choosing the Right Approach for Accurate Diagnosis

Diagnostic scans provide precise fault codes and system insights, enabling faster identification of vehicle issues compared to manual troubleshooting. Manual troubleshooting relies on a technician's expertise to interpret symptoms and test components, which can be beneficial for complex or intermittent problems not detected by scans. Selecting the right diagnostic method depends on the vehicle's technology, problem complexity, and the accuracy required for effective repair.

Diagnostic scan vs manual troubleshooting Infographic

cardiffo.com

cardiffo.com