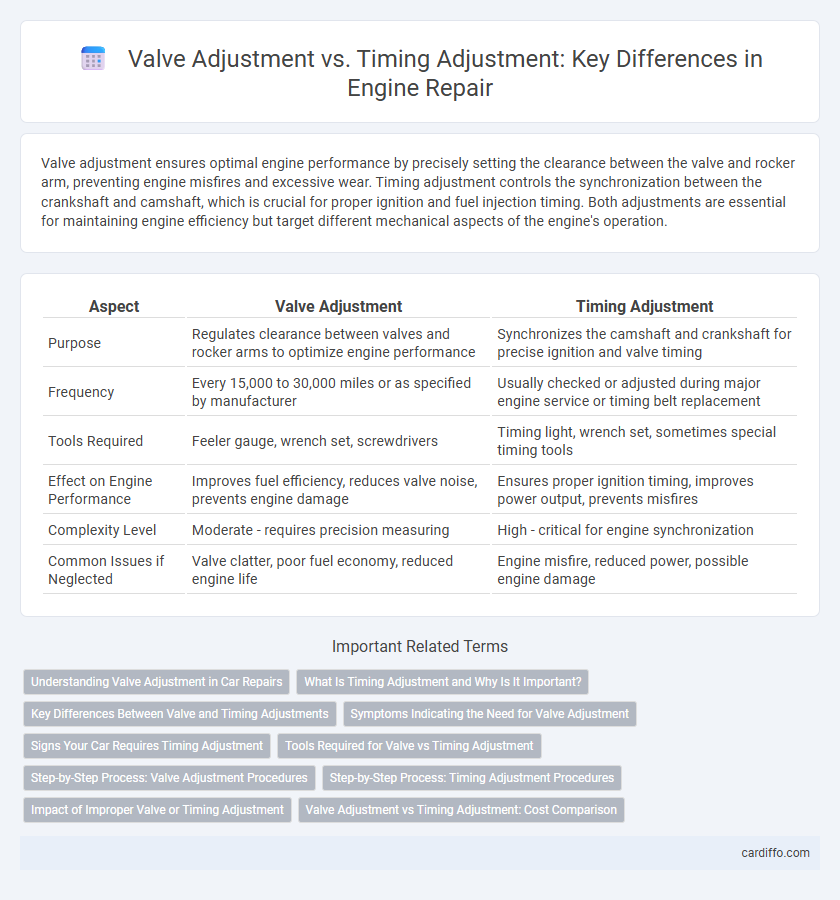

Valve adjustment ensures optimal engine performance by precisely setting the clearance between the valve and rocker arm, preventing engine misfires and excessive wear. Timing adjustment controls the synchronization between the crankshaft and camshaft, which is crucial for proper ignition and fuel injection timing. Both adjustments are essential for maintaining engine efficiency but target different mechanical aspects of the engine's operation.

Table of Comparison

| Aspect | Valve Adjustment | Timing Adjustment |

|---|---|---|

| Purpose | Regulates clearance between valves and rocker arms to optimize engine performance | Synchronizes the camshaft and crankshaft for precise ignition and valve timing |

| Frequency | Every 15,000 to 30,000 miles or as specified by manufacturer | Usually checked or adjusted during major engine service or timing belt replacement |

| Tools Required | Feeler gauge, wrench set, screwdrivers | Timing light, wrench set, sometimes special timing tools |

| Effect on Engine Performance | Improves fuel efficiency, reduces valve noise, prevents engine damage | Ensures proper ignition timing, improves power output, prevents misfires |

| Complexity Level | Moderate - requires precision measuring | High - critical for engine synchronization |

| Common Issues if Neglected | Valve clatter, poor fuel economy, reduced engine life | Engine misfire, reduced power, possible engine damage |

Understanding Valve Adjustment in Car Repairs

Valve adjustment ensures proper clearance between the valve stem and rocker arm, critical for optimal engine performance and fuel efficiency. Timing adjustment, on the other hand, aligns the camshaft and crankshaft to control valve opening and closing relative to piston movement, impacting ignition and engine timing. Understanding valve adjustment focuses on preventing valve damage, maintaining compression, and avoiding misfires by setting precise valve clearance.

What Is Timing Adjustment and Why Is It Important?

Timing adjustment involves synchronizing the engine's camshaft and crankshaft to ensure valves open and close at precise intervals relative to piston movement. Proper timing adjustment optimizes engine performance, prevents misfires, and reduces emission levels. This process is crucial for maintaining fuel efficiency and avoiding serious mechanical damage in internal combustion engines.

Key Differences Between Valve and Timing Adjustments

Valve adjustment involves setting the clearance between the valve stem and rocker arm to ensure proper engine breathing, while timing adjustment focuses on synchronizing the crankshaft and camshaft rotation for optimal ignition and valve operation. Valve adjustments directly affect valve opening and closing precision, influencing engine efficiency and preventing valve damage, whereas timing adjustments regulate the overall engine timing sequence, impacting power delivery and fuel combustion. Both procedures require precise calibration but target different components and performance aspects critical to engine operation.

Symptoms Indicating the Need for Valve Adjustment

Symptoms indicating the need for valve adjustment include rough engine idling, decreased fuel efficiency, and unusual engine noise such as tapping or knocking sounds. Misadjusted valves can cause poor engine performance, including hesitation during acceleration and increased exhaust emissions. Detecting these issues early prevents further engine damage and ensures optimal valve timing and operation.

Signs Your Car Requires Timing Adjustment

Signs your car requires timing adjustment include engine misfires, rough idling, and decreased fuel efficiency. Delayed or erratic spark timing can cause poor acceleration and engine knocking sounds. Observing these symptoms early helps prevent severe engine damage and ensures optimal performance.

Tools Required for Valve vs Timing Adjustment

Valve adjustment requires precise feeler gauges to measure and set the clearance between the valve stem and rocker arm, while timing adjustment demands timing lights or stroboscopes to accurately align the ignition or camshaft timing marks. Specialized wrenches and screwdrivers are essential for both procedures, but timing adjustment may also necessitate a harmonic balancer puller or camshaft locking tools for proper alignment. Accurate tool selection ensures optimal engine performance and prevents mechanical damage during these critical maintenance tasks.

Step-by-Step Process: Valve Adjustment Procedures

Valve adjustment procedures involve precisely measuring and setting the clearance between the valve stem and rocker arm to ensure optimal engine performance. The step-by-step process typically includes removing the valve cover, rotating the engine to the specified position based on the firing order, using a feeler gauge to measure the current gap, and adjusting the clearance by tightening or loosening the valve adjusters to manufacturer specifications. Properly executed valve adjustments improve engine efficiency, reduce wear, and prevent issues such as poor idling or engine misfires.

Step-by-Step Process: Timing Adjustment Procedures

Timing adjustment procedures involve setting the engine's timing marks to ensure the spark plug ignites the fuel-air mixture at the optimal point in the combustion cycle. Begin by locating the timing marks on the crankshaft pulley and timing cover, then use a timing light or dial gauge to align the marks according to the manufacturer's specifications. Carefully loosen the distributor lock and rotate it until the timing marks match the specified degrees before tightening the lock bolt to secure the setting.

Impact of Improper Valve or Timing Adjustment

Improper valve adjustment can cause engine misfires, reduced fuel efficiency, and increased emissions due to incorrect valve clearance affecting combustion. Incorrect timing adjustment disrupts the precise synchronization between the crankshaft and camshaft, leading to poor engine performance, potential engine damage, and increased wear on internal components. Both errors compromise engine reliability and longevity, emphasizing the importance of accurate and regular maintenance.

Valve Adjustment vs Timing Adjustment: Cost Comparison

Valve adjustment typically costs between $100 and $200, depending on the engine type and labor rates, while timing adjustment can range from $150 to $400 due to its complexity. Valve adjustment involves fine-tuning the clearance between valves and rocker arms to ensure optimal engine performance and efficiency. Timing adjustment requires precise realignment of the engine's camshaft and crankshaft, often demanding more labor-intensive work and specialized tools, which increases overall expenses.

Valve adjustment vs timing adjustment Infographic

cardiffo.com

cardiffo.com