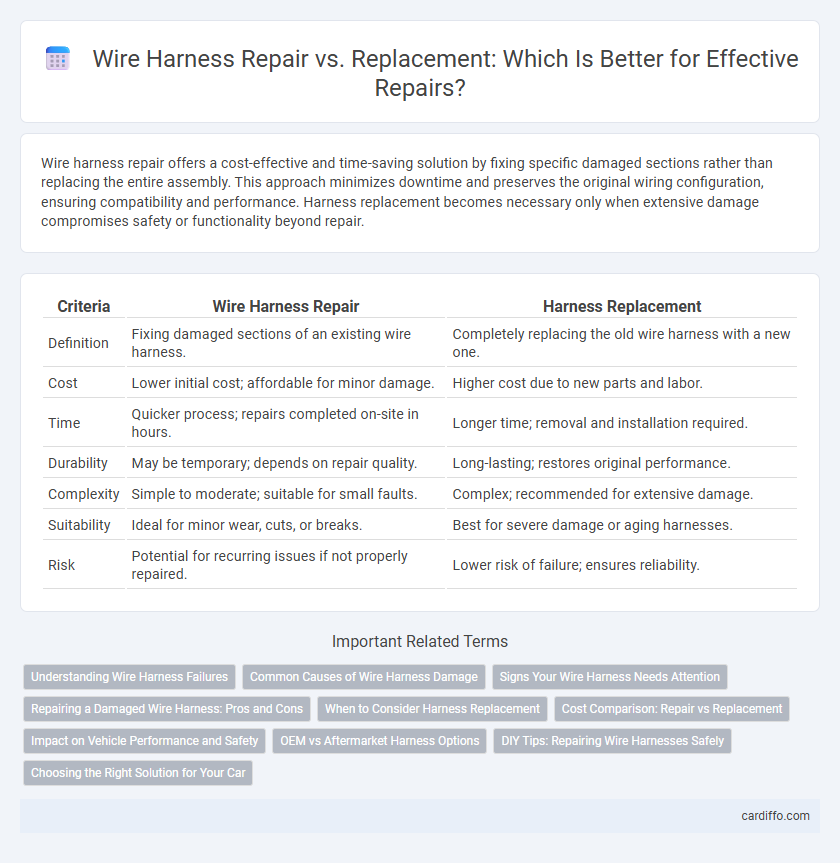

Wire harness repair offers a cost-effective and time-saving solution by fixing specific damaged sections rather than replacing the entire assembly. This approach minimizes downtime and preserves the original wiring configuration, ensuring compatibility and performance. Harness replacement becomes necessary only when extensive damage compromises safety or functionality beyond repair.

Table of Comparison

| Criteria | Wire Harness Repair | Harness Replacement |

|---|---|---|

| Definition | Fixing damaged sections of an existing wire harness. | Completely replacing the old wire harness with a new one. |

| Cost | Lower initial cost; affordable for minor damage. | Higher cost due to new parts and labor. |

| Time | Quicker process; repairs completed on-site in hours. | Longer time; removal and installation required. |

| Durability | May be temporary; depends on repair quality. | Long-lasting; restores original performance. |

| Complexity | Simple to moderate; suitable for small faults. | Complex; recommended for extensive damage. |

| Suitability | Ideal for minor wear, cuts, or breaks. | Best for severe damage or aging harnesses. |

| Risk | Potential for recurring issues if not properly repaired. | Lower risk of failure; ensures reliability. |

Understanding Wire Harness Failures

Wire harness failures commonly result from physical damage, corrosion, and connector degradation, leading to electrical shorts or intermittent connectivity issues. Repairing wire harnesses involves identifying and correcting specific damaged sections to restore function while maintaining cost-efficiency and minimizing downtime. Replacement is often necessary when damage is extensive, irreparable, or when safety standards and reliability cannot be ensured through repairs alone.

Common Causes of Wire Harness Damage

Common causes of wire harness damage include physical abrasion, exposure to moisture and chemicals, and electrical faults such as short circuits or overloads. Wire harness repair addresses localized issues like broken wires or connector corrosion, while harness replacement is necessary when extensive damage compromises overall functionality. Understanding the typical sources of damage ensures effective maintenance and reduces downtime in electrical systems.

Signs Your Wire Harness Needs Attention

Frayed wires, burnt insulation, and intermittent electrical issues are key signs your wire harness needs attention. Frequent warning lights or malfunctioning connectors indicate potential damage requiring repair or replacement. Addressing these symptoms promptly prevents further electrical failures and costly replacements.

Repairing a Damaged Wire Harness: Pros and Cons

Repairing a damaged wire harness can save time and reduce costs compared to full harness replacement, particularly when the damage is localized and the original harness is otherwise intact. However, repair may introduce reliability issues if not performed with precision, risking electrical faults, corrosion, or compromised insulation that can lead to system failures. For critical applications, assessing the extent of damage and weighing repair feasibility against long-term durability and safety is essential before choosing repair over replacement.

When to Consider Harness Replacement

Harness replacement should be considered when the wire harness exhibits extensive damage, such as multiple broken wires, severe corrosion, or insulation degradation that compromises safety and performance. If repeated repairs fail to restore functionality or if the harness is involved in critical systems like airbags or engine management, replacement ensures reliability and compliance with industry standards. Evaluating cost-effectiveness, vehicle age, and potential future failures supports the decision to replace rather than repeatedly repair the wire harness.

Cost Comparison: Repair vs Replacement

Wire harness repair typically costs 30-50% less than a full harness replacement, making it a budget-friendly option for minor damages. Replacement involves higher expenses due to new materials and labor-intensive installation, often ranging from $200 to $1,000 or more depending on vehicle complexity. Choosing repair can extend the lifespan of the existing harness while significantly reducing immediate repair costs.

Impact on Vehicle Performance and Safety

Wire harness repair preserves original wiring integrity, maintaining optimal electrical conductivity that ensures stable vehicle performance and reduces the risk of electrical failures. Harness replacement, while costly, can eliminate hidden damage that compromises safety features like airbags and ABS, enhancing overall vehicle reliability. Choosing between repair and replacement directly affects critical systems' functionality and the vehicle's operational safety standards.

OEM vs Aftermarket Harness Options

OEM wire harness repair preserves original manufacturer specifications, ensuring compatibility and maintaining vehicle warranty, while aftermarket harness replacement offers cost-effective alternatives with varying quality standards. Selecting OEM harnesses guarantees precise fit and performance aligned with the vehicle's design, whereas aftermarket options may differ in materials and durability, potentially affecting long-term reliability. Technicians assess the extent of damage and application requirements to recommend repair or replacement, prioritizing safety and functionality in electrical system restoration.

DIY Tips: Repairing Wire Harnesses Safely

Repairing wire harnesses requires careful inspection to identify damaged wires, connectors, or insulation before proceeding with soldering or crimping splices. Using high-quality heat shrink tubing and proper tools such as wire strippers and multimeters ensures secure electrical connections and prevents short circuits. Always disconnect the power source and wear insulated gloves to enhance safety during DIY wire harness repairs.

Choosing the Right Solution for Your Car

Wire harness repair offers a cost-effective and faster solution for minor damage or isolated faults, preserving the original components and maintaining vehicle performance. Harness replacement is essential when extensive damage, corrosion, or multiple wiring failures compromise safety and functionality, ensuring reliable electrical connections and preventing future issues. Evaluating the extent of damage, vehicle age, and budget constraints helps determine whether repair or replacement is the optimal choice for your car's wiring system.

Wire harness repair vs Harness replacement Infographic

cardiffo.com

cardiffo.com