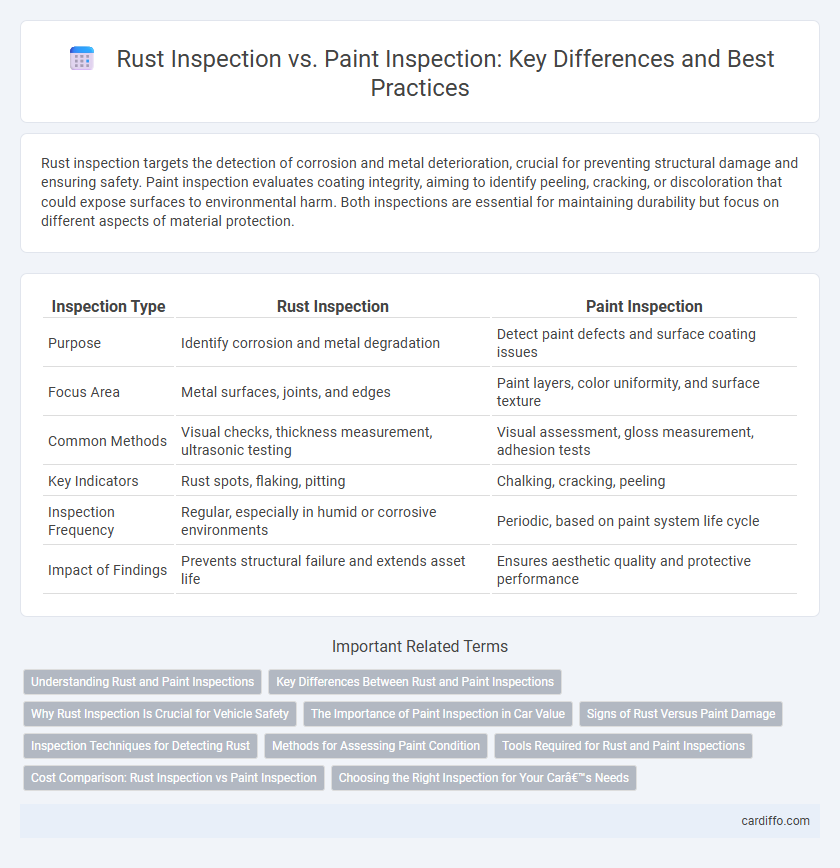

Rust inspection targets the detection of corrosion and metal deterioration, crucial for preventing structural damage and ensuring safety. Paint inspection evaluates coating integrity, aiming to identify peeling, cracking, or discoloration that could expose surfaces to environmental harm. Both inspections are essential for maintaining durability but focus on different aspects of material protection.

Table of Comparison

| Inspection Type | Rust Inspection | Paint Inspection |

|---|---|---|

| Purpose | Identify corrosion and metal degradation | Detect paint defects and surface coating issues |

| Focus Area | Metal surfaces, joints, and edges | Paint layers, color uniformity, and surface texture |

| Common Methods | Visual checks, thickness measurement, ultrasonic testing | Visual assessment, gloss measurement, adhesion tests |

| Key Indicators | Rust spots, flaking, pitting | Chalking, cracking, peeling |

| Inspection Frequency | Regular, especially in humid or corrosive environments | Periodic, based on paint system life cycle |

| Impact of Findings | Prevents structural failure and extends asset life | Ensures aesthetic quality and protective performance |

Understanding Rust and Paint Inspections

Rust inspection involves assessing metal surfaces for corrosion, pitting, and structural integrity degradation, crucial in industries such as automotive and construction. Paint inspection focuses on evaluating coating thickness, adhesion, and uniformity to prevent surface damage and extend material lifespan. Understanding the distinct criteria and techniques of rust and paint inspections ensures effective maintenance and early identification of potential failures.

Key Differences Between Rust and Paint Inspections

Rust inspection primarily targets corrosion detection by identifying areas where metal surfaces have oxidized, often using visual and tactile methods to assess severity and progression. Paint inspection evaluates the coating's integrity, looking for cracks, peeling, bubbling, or discoloration that indicates protection failure or underlying surface issues. Key differences include rust inspection's focus on metal degradation and structural impact, whereas paint inspection emphasizes protective layer condition and aesthetic maintenance.

Why Rust Inspection Is Crucial for Vehicle Safety

Rust inspection is crucial for vehicle safety because rust can significantly weaken a vehicle's structural integrity, leading to potential frame failure and compromised crashworthiness. Unlike paint inspection, which only assesses superficial damage and aesthetic issues, rust inspection identifies corrosion that might affect critical components such as brake lines, fuel tanks, and suspension parts. Early detection of rust helps prevent costly repairs and ensures the vehicle maintains its designed safety performance standards.

The Importance of Paint Inspection in Car Value

Paint inspection plays a critical role in maintaining a car's resale value by identifying surface damage, fading, and inconsistencies early. Unlike rust inspection, which focuses on structural integrity and corrosion beneath the surface, paint inspection ensures cosmetic appeal and protects against environmental damage. Regular paint assessments help preserve a vehicle's aesthetic quality, directly influencing buyer perception and market price.

Signs of Rust Versus Paint Damage

Rust inspection primarily identifies oxidation signs such as reddish-brown flakes, bubbling under the paint, and rough texture on metal surfaces, indicating corrosion progression. Paint inspection focuses on detecting cracks, peeling, fading, and discoloration that result from environmental exposure or improper application, without underlying metal decay. Differentiating rust from paint damage is crucial for accurate maintenance, as rust compromises structural integrity, while paint issues mainly affect appearance and protection.

Inspection Techniques for Detecting Rust

Inspection techniques for detecting rust prioritize non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and visual inspection enhanced with high-intensity lighting or digital imaging. Ultrasonic testing measures material thickness and identifies subsurface corrosion, while magnetic particle inspection detects surface and near-surface defects in ferrous materials. Advanced techniques increasingly integrate infrared thermography to reveal rust-induced temperature variations, ensuring early and accurate corrosion detection compared to traditional paint inspection methods.

Methods for Assessing Paint Condition

Methods for assessing paint condition include visual inspection using magnification tools to detect cracks, blisters, or discoloration indicating degradation. Thickness gauges measure paint layer consistency, while solvent or adhesion tests evaluate bond strength and resistance to environmental factors. Infrared and UV light inspections reveal subsurface defects and color changes not visible to the naked eye.

Tools Required for Rust and Paint Inspections

Rust inspection requires specialized tools such as ultrasonic thickness gauges, magnetic particle testers, and corrosion probes to accurately detect metal degradation beneath protective coatings. Paint inspection relies on tools like wet film thickness gauges, adhesion testers, and gloss meters to assess coating integrity and surface coverage. Both inspections benefit from portable lighting and magnification devices to enhance visual assessment precision.

Cost Comparison: Rust Inspection vs Paint Inspection

Rust inspection typically incurs higher costs compared to paint inspection due to the need for specialized equipment such as ultrasonic thickness gauges and advanced surface analyzers. Paint inspections generally involve visual assessment and simpler tools like adhesion testers, making them more cost-effective for routine maintenance. Accurate rust detection prevents costly structural damage, often justifying the initial higher expense of rust inspection over the lower-cost paint inspection.

Choosing the Right Inspection for Your Car’s Needs

Rust inspection targets corrosion-prone areas by assessing metal integrity and detecting early stages of oxidation, ensuring the vehicle's structural safety. Paint inspection evaluates the quality and condition of the car's surface finish, identifying imperfections such as scratches, fading, or peeling that affect aesthetics and resale value. Selecting the appropriate inspection depends on whether your priority is preventing metal damage or maintaining exterior appearance.

Rust inspection vs paint inspection Infographic

cardiffo.com

cardiffo.com