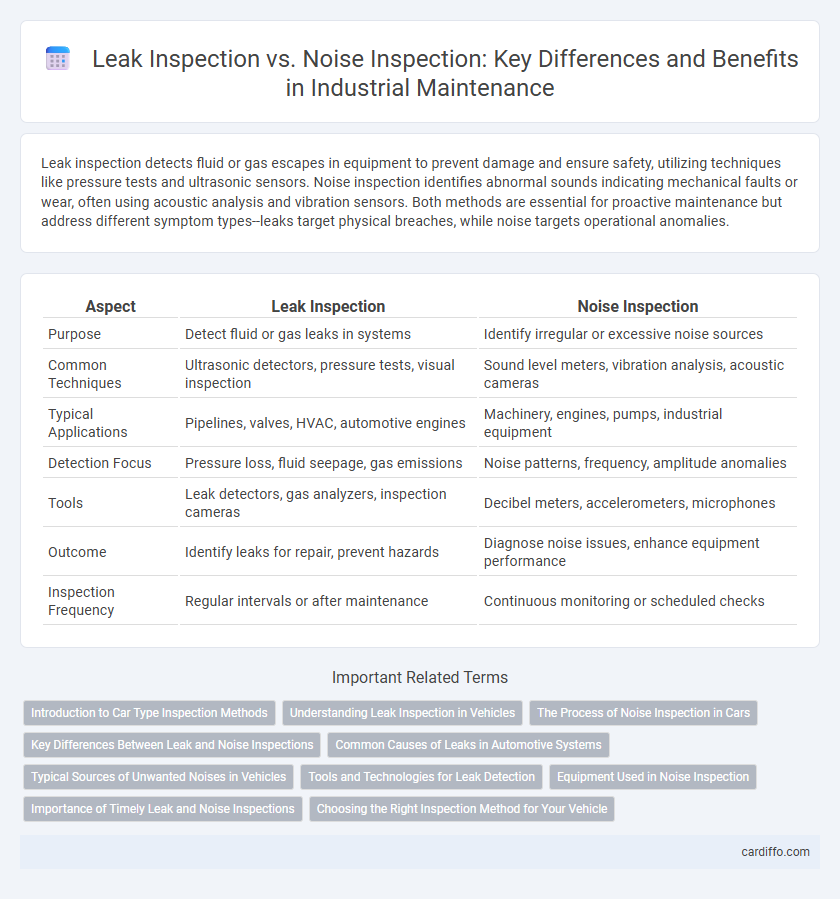

Leak inspection detects fluid or gas escapes in equipment to prevent damage and ensure safety, utilizing techniques like pressure tests and ultrasonic sensors. Noise inspection identifies abnormal sounds indicating mechanical faults or wear, often using acoustic analysis and vibration sensors. Both methods are essential for proactive maintenance but address different symptom types--leaks target physical breaches, while noise targets operational anomalies.

Table of Comparison

| Aspect | Leak Inspection | Noise Inspection |

|---|---|---|

| Purpose | Detect fluid or gas leaks in systems | Identify irregular or excessive noise sources |

| Common Techniques | Ultrasonic detectors, pressure tests, visual inspection | Sound level meters, vibration analysis, acoustic cameras |

| Typical Applications | Pipelines, valves, HVAC, automotive engines | Machinery, engines, pumps, industrial equipment |

| Detection Focus | Pressure loss, fluid seepage, gas emissions | Noise patterns, frequency, amplitude anomalies |

| Tools | Leak detectors, gas analyzers, inspection cameras | Decibel meters, accelerometers, microphones |

| Outcome | Identify leaks for repair, prevent hazards | Diagnose noise issues, enhance equipment performance |

| Inspection Frequency | Regular intervals or after maintenance | Continuous monitoring or scheduled checks |

Introduction to Car Type Inspection Methods

Leak inspection and noise inspection are critical car type inspection methods used to ensure vehicle quality and safety. Leak inspection detects fluid leaks in components such as engines, transmissions, and air conditioning systems through pressure decay, bubble, or UV dye tests. Noise inspection evaluates abnormal sounds originating from the engine, exhaust, or suspension using acoustic sensors and vibration analysis to identify mechanical issues and maintain optimal performance.

Understanding Leak Inspection in Vehicles

Leak inspection in vehicles involves identifying and locating fluid leaks such as oil, coolant, or fuel, which can compromise engine performance and safety. Techniques often include visual checks, pressure testing, and the use of ultraviolet dye to trace leaks accurately. This process is essential for preventing mechanical failures and maintaining optimal vehicle operation, differentiating it from noise inspection that targets abnormal sounds indicating mechanical issues.

The Process of Noise Inspection in Cars

Noise inspection in cars involves using specialized microphones and sensors to detect abnormal sounds from the engine, exhaust, and other vehicle components. Technicians analyze acoustic data to identify issues such as bearing wear, exhaust leaks, or engine misfires that may not be visible during leak inspections. This process enhances vehicle safety and performance by diagnosing problems early through precise sound pattern recognition.

Key Differences Between Leak and Noise Inspections

Leak inspection primarily detects and locates gas or fluid leaks using ultrasonic or infrared sensors, whereas noise inspection focuses on identifying abnormal sound patterns that indicate mechanical faults or system malfunctions. Leak inspections target specific emissions by analyzing frequency ranges associated with leaks, while noise inspections cover broader acoustic signatures to diagnose equipment issues. Both methods employ advanced sensor technologies, but their distinct objectives and detection parameters make them complementary in overall maintenance strategies.

Common Causes of Leaks in Automotive Systems

Common causes of leaks in automotive systems include worn or damaged gaskets, cracked hoses, and faulty seals in components such as the engine, radiator, and fuel system. Inspecting for leaks involves identifying visible fluid escape, corrosion, or pressure drops, whereas noise inspection detects irregular sounds indicating leaks or mechanical issues. Understanding these causes helps prioritize targeted leak inspections to maintain vehicle safety and performance.

Typical Sources of Unwanted Noises in Vehicles

Typical sources of unwanted noises in vehicles during leak and noise inspections include air or fluid leaks from engine components, exhaust systems, and HVAC units, which generate hissing or bubbling sounds detectable by specialized sensors. Mechanical vibrations from worn bearings, loose fasteners, or damaged suspension parts often produce rattling, squeaking, or grinding noises, signifying potential safety risks. Identifying these distinct acoustic signatures helps technicians accurately diagnose issues, improve vehicle performance, and ensure passenger comfort.

Tools and Technologies for Leak Detection

Leak inspection primarily relies on ultrasonic detectors, infrared thermography cameras, and gas analyzers to identify escaping gases or liquids with high precision. Noise inspection uses acoustic emission sensors and vibration analyzers to detect abnormal sound patterns indicating leaks or structural faults. Advanced technologies like AI-driven pattern recognition and IoT-enabled sensors enhance real-time monitoring and accurate localization of leaks in both methods.

Equipment Used in Noise Inspection

Noise inspection employs specialized acoustic devices such as ultrasonic detectors, microphones, and sound level meters to identify abnormal sound patterns indicating leaks. These instruments capture high-frequency noises beyond human hearing, enabling early detection of small leaks in pressurized systems. Ultrasonic detectors are particularly effective in noisy industrial environments where visual or odor-based leak detection methods are insufficient.

Importance of Timely Leak and Noise Inspections

Timely leak inspections prevent hazardous substance releases, reducing environmental damage and costly repairs. Noise inspections identify harmful sound levels early, protecting workers from hearing loss and ensuring regulatory compliance. Both inspections are critical for maintaining safety standards and operational efficiency in industrial settings.

Choosing the Right Inspection Method for Your Vehicle

Leak inspection identifies fluid escapes by detecting visible signs or using sensors to pinpoint sources, essential for maintaining engine and brake system integrity. Noise inspection analyzes abnormal sounds from the vehicle's components, revealing issues in the exhaust, suspension, or drive train before leaks become apparent. Selecting between leak and noise inspection depends on symptoms observed; early noise detection prevents severe damage, while leak inspection addresses existing fluid loss and potential contamination.

Leak inspection vs noise inspection Infographic

cardiffo.com

cardiffo.com