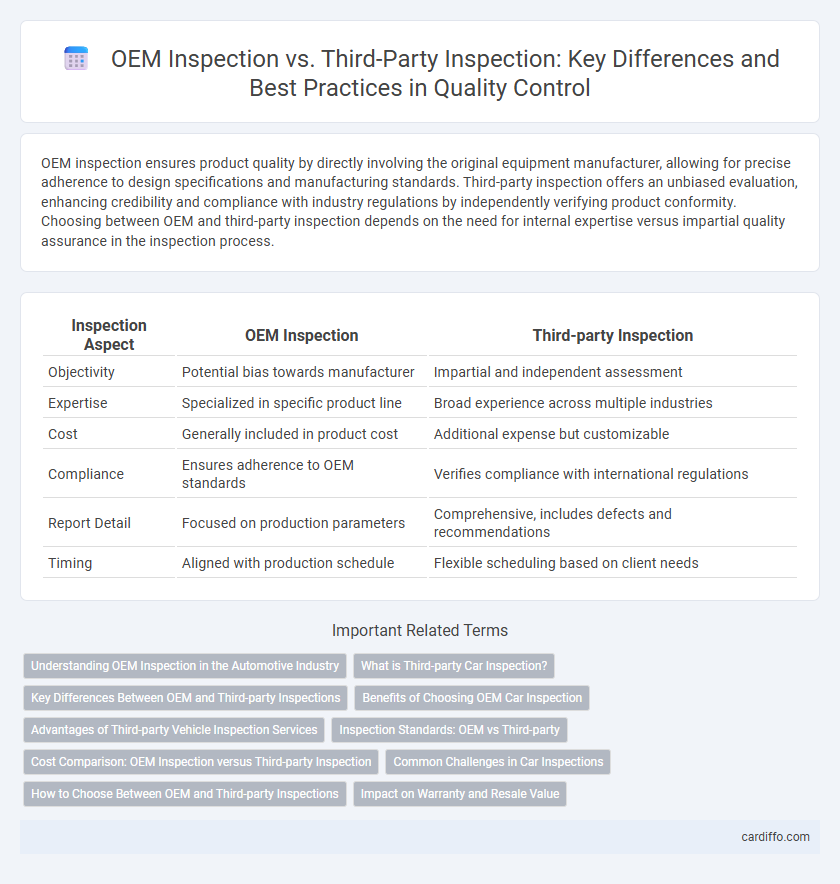

OEM inspection ensures product quality by directly involving the original equipment manufacturer, allowing for precise adherence to design specifications and manufacturing standards. Third-party inspection offers an unbiased evaluation, enhancing credibility and compliance with industry regulations by independently verifying product conformity. Choosing between OEM and third-party inspection depends on the need for internal expertise versus impartial quality assurance in the inspection process.

Table of Comparison

| Inspection Aspect | OEM Inspection | Third-party Inspection |

|---|---|---|

| Objectivity | Potential bias towards manufacturer | Impartial and independent assessment |

| Expertise | Specialized in specific product line | Broad experience across multiple industries |

| Cost | Generally included in product cost | Additional expense but customizable |

| Compliance | Ensures adherence to OEM standards | Verifies compliance with international regulations |

| Report Detail | Focused on production parameters | Comprehensive, includes defects and recommendations |

| Timing | Aligned with production schedule | Flexible scheduling based on client needs |

Understanding OEM Inspection in the Automotive Industry

OEM inspection in the automotive industry involves rigorous quality checks performed by the original equipment manufacturer to ensure parts and assemblies meet precise design specifications and safety standards before reaching assembly lines. This internal inspection process supports consistent product reliability and compliance with regulatory requirements while reducing the risk of defects in final vehicle production. OEM inspection leverages advanced diagnostic tools and standardized protocols tailored specifically to the manufacturer's engineering criteria for optimal performance assurance.

What is Third-party Car Inspection?

Third-party car inspection involves an independent organization evaluating a vehicle's condition without any affiliation to the manufacturer or seller, ensuring unbiased and reliable assessments. This inspection covers critical aspects such as engine performance, safety features, and structural integrity, helping buyers make informed decisions. Unlike OEM inspections that follow manufacturer-specific protocols, third-party inspections adhere to standardized industry criteria for transparency and trustworthiness.

Key Differences Between OEM and Third-party Inspections

OEM inspections are conducted by the original equipment manufacturer, ensuring adherence to proprietary standards, specifications, and warranty requirements, providing firsthand knowledge of the product. Third-party inspections offer unbiased assessments performed by independent organizations, enhancing credibility, compliance with international standards, and reducing conflicts of interest. Key differences include scope of inspection, reporting objectivity, and accountability, with OEM inspections focused on manufacturing conformity and third-party inspections emphasizing quality assurance and regulatory compliance.

Benefits of Choosing OEM Car Inspection

OEM car inspections ensure compliance with manufacturer standards, leveraging proprietary diagnostic tools and expert knowledge for accurate assessment. These inspections often detect potential issues earlier, reducing repair costs and enhancing vehicle longevity. Choosing OEM inspection boosts warranty validity and aligns repairs with original specifications, maximizing performance and safety.

Advantages of Third-party Vehicle Inspection Services

Third-party vehicle inspection services offer unbiased and impartial assessments, enhancing trust and transparency for buyers and sellers. These inspections leverage certified experts who follow standardized protocols, ensuring consistent and thorough evaluations of OEM vehicles. Independent inspections also help identify hidden defects or discrepancies, reducing potential disputes and increasing overall vehicle safety and value.

Inspection Standards: OEM vs Third-party

OEM inspections adhere strictly to manufacturer-specific standards and technical specifications, ensuring products meet original design and performance criteria. Third-party inspections follow independent industry-wide standards such as ISO, ASTM, or API, providing unbiased assessments against internationally recognized benchmarks. Choosing between OEM and third-party inspection standards depends on the need for manufacturer compliance verification or objective quality assurance.

Cost Comparison: OEM Inspection versus Third-party Inspection

OEM inspection typically incurs higher costs due to integrated service packages and in-depth product knowledge, which can lead to reduced risk of defects. Third-party inspection often offers more flexible pricing options and competitive rates by separating inspection from production, enabling businesses to control expenses more effectively. Cost efficiency depends on the specific industry needs, volume, and the complexity of the products being inspected.

Common Challenges in Car Inspections

OEM inspections and third-party inspections in car evaluations often face common challenges such as inconsistent quality standards, varying inspection criteria, and potential bias. OEM inspections may prioritize brand-specific benchmarks that can overlook broader safety issues, while third-party inspections might encounter difficulties in accessing proprietary vehicle information. Both methods struggle with ensuring comprehensive defect detection and maintaining transparent reporting to provide accurate assessments.

How to Choose Between OEM and Third-party Inspections

Choosing between OEM inspection and third-party inspection depends on factors like objectivity, cost, and expertise required. OEM inspections offer in-depth product knowledge and potentially lower costs but may lack impartiality. Third-party inspections guarantee unbiased assessments and regulatory compliance but often involve higher fees and extended timelines.

Impact on Warranty and Resale Value

OEM inspection ensures compliance with manufacturer standards, preserving warranty validity and enhancing resale value by guaranteeing product authenticity and quality. Third-party inspection provides unbiased verification, which may support warranty claims but does not guarantee OEM warranty coverage, potentially affecting resale value. Choosing an inspection method directly influences warranty protection and buyer confidence in the product's condition.

OEM Inspection vs Third-party Inspection Infographic

cardiffo.com

cardiffo.com