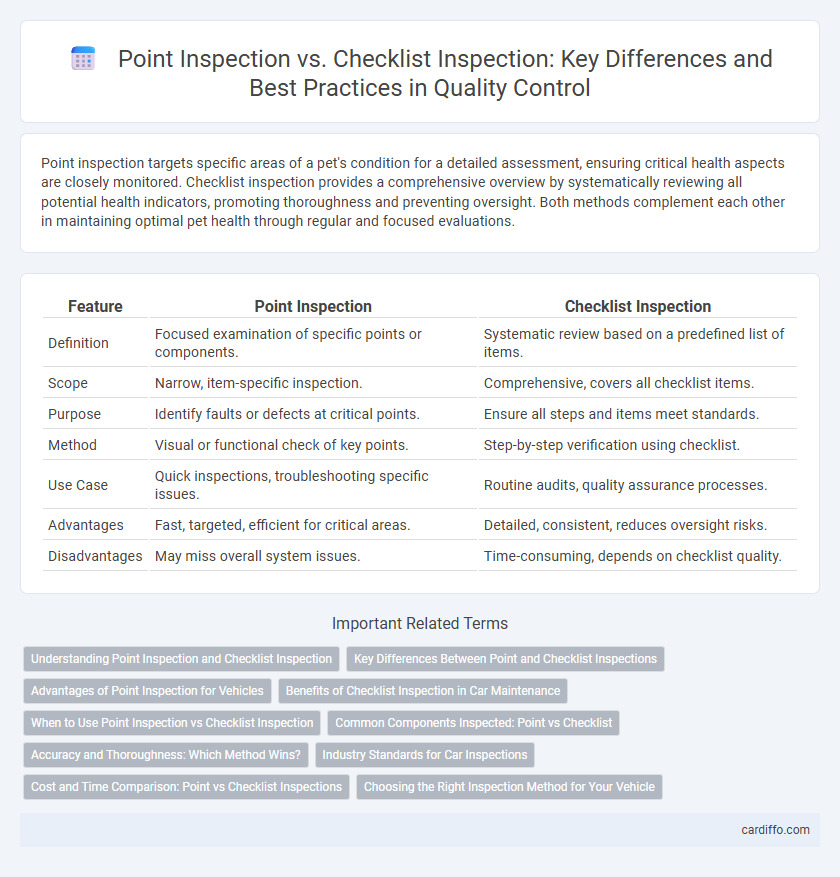

Point inspection targets specific areas of a pet's condition for a detailed assessment, ensuring critical health aspects are closely monitored. Checklist inspection provides a comprehensive overview by systematically reviewing all potential health indicators, promoting thoroughness and preventing oversight. Both methods complement each other in maintaining optimal pet health through regular and focused evaluations.

Table of Comparison

| Feature | Point Inspection | Checklist Inspection |

|---|---|---|

| Definition | Focused examination of specific points or components. | Systematic review based on a predefined list of items. |

| Scope | Narrow, item-specific inspection. | Comprehensive, covers all checklist items. |

| Purpose | Identify faults or defects at critical points. | Ensure all steps and items meet standards. |

| Method | Visual or functional check of key points. | Step-by-step verification using checklist. |

| Use Case | Quick inspections, troubleshooting specific issues. | Routine audits, quality assurance processes. |

| Advantages | Fast, targeted, efficient for critical areas. | Detailed, consistent, reduces oversight risks. |

| Disadvantages | May miss overall system issues. | Time-consuming, depends on checklist quality. |

Understanding Point Inspection and Checklist Inspection

Point inspection targets specific areas or components for detailed assessment to ensure compliance with standards or identify defects, making it ideal for pinpointing issues. Checklist inspection involves a systematic review using a predefined list of criteria or items, ensuring thorough coverage and consistency across inspections. Both methods enhance quality control but differ in scope, with point inspection offering focused analysis and checklist inspection providing comprehensive evaluation.

Key Differences Between Point and Checklist Inspections

Point inspections focus on evaluating specific components or criteria at a single point in time, providing a detailed assessment of individual elements. Checklist inspections use a standardized list of items to ensure all aspects of a system or process are reviewed consistently, enhancing thoroughness and compliance. Key differences include the targeted, component-specific nature of point inspections versus the systematic, procedural approach of checklist inspections.

Advantages of Point Inspection for Vehicles

Point inspection for vehicles offers precise identification of specific issues by targeting critical components individually, enhancing diagnostic accuracy compared to checklist inspection's broad approach. This method enables focused resource allocation and timely repairs, reducing downtime and preventing minor faults from escalating into costly problems. The detailed nature of point inspection also supports better record-keeping and trend analysis, improving long-term vehicle maintenance strategies.

Benefits of Checklist Inspection in Car Maintenance

Checklist inspection in car maintenance ensures thorough coverage of all critical vehicle components, reducing the risk of overlooked issues and enhancing overall safety. This method standardizes the inspection process, improving efficiency and consistency while simplifying record-keeping for future reference. Utilizing checklist inspections facilitates early detection of potential problems, minimizing costly repairs and extending vehicle lifespan.

When to Use Point Inspection vs Checklist Inspection

Point inspection is ideal for targeted assessments where specific components or issues require detailed evaluation, such as examining a malfunctioning engine part. Checklist inspection suits comprehensive evaluations covering multiple elements systematically, like routine safety audits or equipment maintenance. Choose point inspection for precision diagnostics and checklist inspection for ensuring overall compliance and completeness.

Common Components Inspected: Point vs Checklist

Point inspection focuses on specific components such as brakes, tires, and engine parts, providing a targeted assessment of key vehicle functions. Checklist inspection covers a broader range of elements, including fluid levels, lights, and safety features, ensuring a comprehensive evaluation. Both inspection types emphasize common components like suspension systems, exhaust, and battery condition, but checklist inspections offer a more detailed review by systematically verifying each item.

Accuracy and Thoroughness: Which Method Wins?

Point inspection offers high accuracy by targeting specific defects or areas, enabling precise identification of issues. Checklist inspection ensures thoroughness by systematically covering all predefined criteria, reducing the risk of overlooked faults. For optimal results, combining point inspection's precision with checklist inspection's comprehensive scope maximizes both accuracy and thoroughness in quality control.

Industry Standards for Car Inspections

Point inspection involves examining specific components of a vehicle based on critical industry standards such as the National Institute for Automotive Service Excellence (ASE) guidelines, targeting essential systems like brakes, suspension, and engine performance. Checklist inspection employs a comprehensive, itemized list derived from standards set by organizations like the International Organization for Standardization (ISO 9001) and the Society of Automotive Engineers (SAE), ensuring systematic evaluation of safety features, emissions, and fluid levels. Both methods align with regulatory requirements to maintain vehicle safety, reliability, and compliance with environmental standards during routine car inspections.

Cost and Time Comparison: Point vs Checklist Inspections

Point inspections typically incur lower costs and require less time due to their targeted approach, focusing on specific critical areas or equipment. Checklist inspections, while more comprehensive, involve a higher investment of time and resources as they systematically cover a broad range of items to ensure thoroughness. Organizations must balance the efficiency of point inspections with the detailed scope of checklist inspections to optimize maintenance budgets and operational downtime.

Choosing the Right Inspection Method for Your Vehicle

Point inspection targets specific components or issues, offering a detailed assessment of critical areas such as brakes, tires, or engine performance. Checklist inspection employs a comprehensive list to systematically evaluate the entire vehicle, ensuring no part is overlooked during routine maintenance. Selecting the appropriate method depends on whether a focused diagnosis or a complete vehicle overview is needed to maintain safety and performance.

Point inspection vs checklist inspection Infographic

cardiffo.com

cardiffo.com