OBD scan provides precise diagnostic data by reading error codes directly from the vehicle's computer system, enabling quick identification of engine and emissions issues. Visual inspection relies on experienced technicians examining physical components for wear, leaks, or damage, offering insights into the overall condition and potential mechanical problems. Combining OBD scan results with a thorough visual inspection ensures a comprehensive assessment of vehicle health and safety.

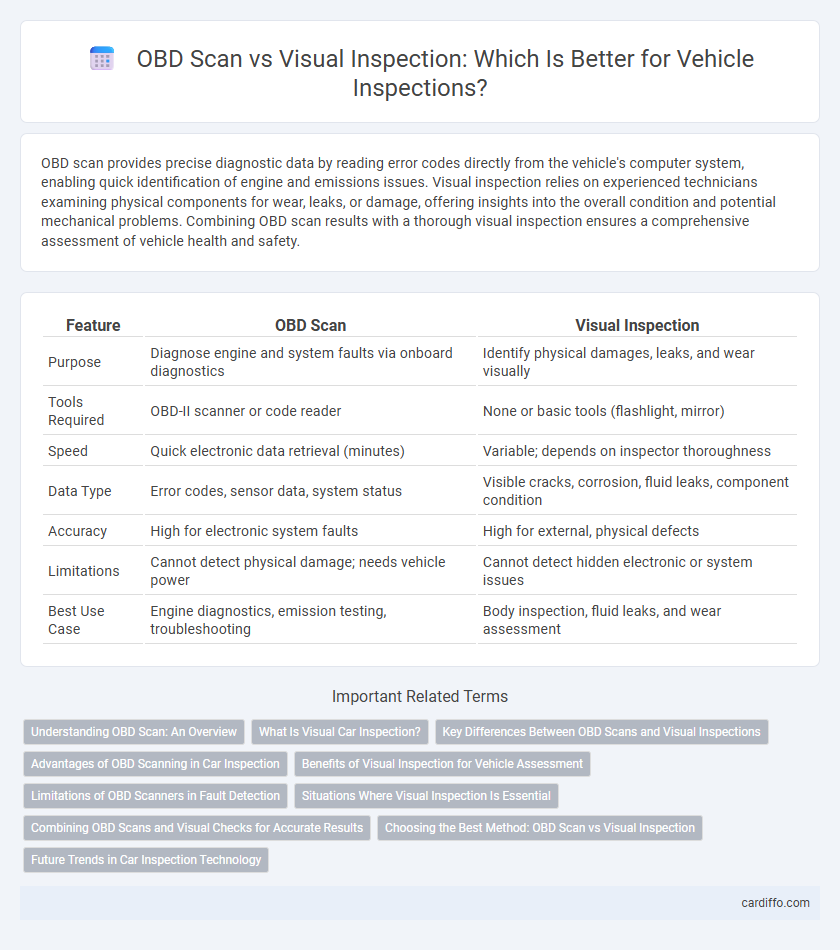

Table of Comparison

| Feature | OBD Scan | Visual Inspection |

|---|---|---|

| Purpose | Diagnose engine and system faults via onboard diagnostics | Identify physical damages, leaks, and wear visually |

| Tools Required | OBD-II scanner or code reader | None or basic tools (flashlight, mirror) |

| Speed | Quick electronic data retrieval (minutes) | Variable; depends on inspector thoroughness |

| Data Type | Error codes, sensor data, system status | Visible cracks, corrosion, fluid leaks, component condition |

| Accuracy | High for electronic system faults | High for external, physical defects |

| Limitations | Cannot detect physical damage; needs vehicle power | Cannot detect hidden electronic or system issues |

| Best Use Case | Engine diagnostics, emission testing, troubleshooting | Body inspection, fluid leaks, and wear assessment |

Understanding OBD Scan: An Overview

OBD Scan systems provide real-time data by accessing a vehicle's onboard diagnostics, capturing error codes related to engine performance, emissions, and system faults. This method allows inspectors to quickly pinpoint specific issues that may not be visible through a standard visual inspection, such as sensor malfunctions or electronic control unit (ECU) errors. Understanding the OBD Scan's capability to monitor live data and stored trouble codes is crucial for efficient vehicle diagnostics and maintenance.

What Is Visual Car Inspection?

Visual car inspection involves a thorough examination of a vehicle's exterior and interior components to detect visible signs of damage, wear, or corrosion. Technicians assess critical areas such as tires, lights, fluid leaks, and the condition of belts and hoses to identify potential safety hazards or maintenance needs. This method complements OBD scans by revealing issues not detectable through electronic diagnostics, ensuring comprehensive vehicle assessment.

Key Differences Between OBD Scans and Visual Inspections

OBD scans provide precise diagnostic trouble codes (DTCs) by accessing the vehicle's onboard computer system, enabling detection of engine, transmission, and emission-related issues often invisible to the naked eye. Visual inspections rely on physical examination, assessing components such as belts, hoses, and fluid levels to identify external wear, damage, or leaks. The key difference lies in OBD scans offering digital fault detection and real-time data, whereas visual inspections focus on surface condition and immediate physical evidence.

Advantages of OBD Scanning in Car Inspection

OBD scanning provides precise diagnostic data by accessing the vehicle's onboard computer system, enabling technicians to quickly identify engine and emission-related issues that are not visible during a visual inspection. It enhances accuracy in detecting faults in real-time, reducing the risk of overlooking critical problems such as sensor failures, misfires, and emission system malfunctions. OBD scanning streamlines the inspection process by offering immediate error codes and live data, leading to faster repairs and improved vehicle safety compliance.

Benefits of Visual Inspection for Vehicle Assessment

Visual inspection for vehicle assessment provides immediate detection of external damages, corrosion, and wear that OBD scans cannot identify, offering a comprehensive understanding of the vehicle's physical condition. It enables real-time evaluation of components like tires, brakes, and fluid leaks, which are critical for safety and performance. This method supports early identification of issues before they trigger onboard diagnostic trouble codes, enhancing preventive maintenance and overall vehicle reliability.

Limitations of OBD Scanners in Fault Detection

OBD scanners primarily detect faults related to engine and emission control systems but often miss mechanical issues not monitored by onboard sensors. Visual inspection can identify physical damages, worn components, and irregularities invisible to OBD systems. Relying solely on OBD scans risks overlooking critical safety or structural problems, emphasizing the importance of comprehensive visual diagnostics.

Situations Where Visual Inspection Is Essential

Visual inspection is essential in identifying physical damages, loose connections, and wear that an OBD scan cannot detect, such as cracked hoses, frayed belts, and corrosion on terminals. It provides a comprehensive assessment of the vehicle's exterior and engine components, revealing issues like fluid leaks and structural damage. In many cases, combining visual inspection with OBD scanning ensures a more accurate diagnosis and effective maintenance strategy.

Combining OBD Scans and Visual Checks for Accurate Results

Combining OBD scan tools with thorough visual inspections enhances diagnostic accuracy by identifying both electronic fault codes and visible mechanical issues. OBD scans quickly detect engine malfunctions and sensor failures, while visual inspections reveal wear, leaks, or damage not captured electronically. This integrated approach ensures comprehensive vehicle health assessments, reducing the risk of overlooked problems and costly repairs.

Choosing the Best Method: OBD Scan vs Visual Inspection

Choosing the best method for vehicle diagnostics depends on the accuracy and type of information required; OBD scan tools provide precise data on engine codes and sensor statuses, ideal for identifying electronic and emission-related issues. Visual inspection allows technicians to assess physical damage, wear, and external components such as belts, hoses, and fluid levels, which OBD scans cannot detect. Combining both methods ensures comprehensive vehicle evaluation, maximizing maintenance effectiveness and safety assurance.

Future Trends in Car Inspection Technology

Future trends in car inspection technology emphasize the integration of OBD scans with advanced visual inspection tools, leveraging AI-driven image recognition to detect both electronic and physical issues swiftly. Enhanced connectivity allows real-time data transmission from onboard diagnostics combined with high-resolution camera systems, improving accuracy and predictive maintenance capabilities. This fusion of technologies aims to reduce human error, accelerate inspection timelines, and support autonomous vehicle safety standards.

OBD Scan vs Visual Inspection Infographic

cardiffo.com

cardiffo.com