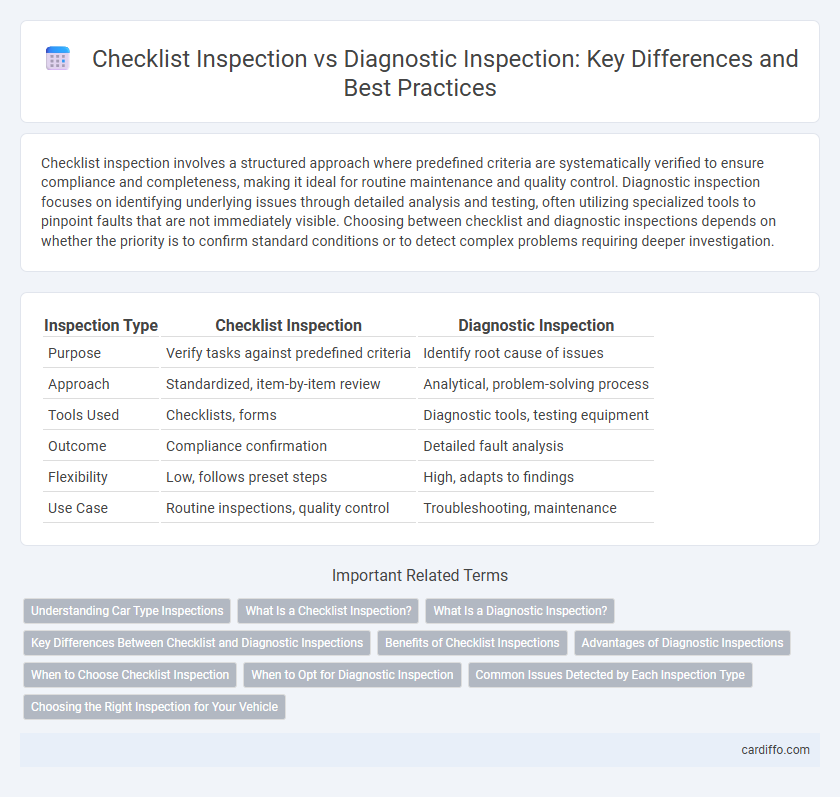

Checklist inspection involves a structured approach where predefined criteria are systematically verified to ensure compliance and completeness, making it ideal for routine maintenance and quality control. Diagnostic inspection focuses on identifying underlying issues through detailed analysis and testing, often utilizing specialized tools to pinpoint faults that are not immediately visible. Choosing between checklist and diagnostic inspections depends on whether the priority is to confirm standard conditions or to detect complex problems requiring deeper investigation.

Table of Comparison

| Inspection Type | Checklist Inspection | Diagnostic Inspection |

|---|---|---|

| Purpose | Verify tasks against predefined criteria | Identify root cause of issues |

| Approach | Standardized, item-by-item review | Analytical, problem-solving process |

| Tools Used | Checklists, forms | Diagnostic tools, testing equipment |

| Outcome | Compliance confirmation | Detailed fault analysis |

| Flexibility | Low, follows preset steps | High, adapts to findings |

| Use Case | Routine inspections, quality control | Troubleshooting, maintenance |

Understanding Car Type Inspections

Checklist inspections involve systematically verifying specific components and functions against a predefined list tailored to common car types, ensuring compliance with routine maintenance standards. Diagnostic inspections utilize advanced tools and sensors to identify hidden or complex issues based on real-time data from the vehicle's onboard computer systems, often employed for newer or technologically advanced car models. Understanding the distinct approaches aids in selecting the appropriate inspection strategy for different vehicle types, optimizing accuracy and maintenance efficiency.

What Is a Checklist Inspection?

A checklist inspection is a structured assessment method that uses a predefined list of criteria or items to be verified during the inspection process. It ensures consistency, completeness, and accuracy by systematically evaluating each element against established standards or requirements. This type of inspection is essential for routine quality control, compliance verification, and identifying obvious defects or issues.

What Is a Diagnostic Inspection?

A diagnostic inspection involves a detailed evaluation focused on identifying the root causes of specific issues or malfunctions within a system or equipment. Unlike a checklist inspection, which follows a predefined list to verify standard conditions, diagnostic inspections utilize specialized tools and techniques to analyze performance and detect hidden faults. This process is essential for developing targeted repair strategies and preventing future failures.

Key Differences Between Checklist and Diagnostic Inspections

Checklist inspections rely on predefined criteria and itemized lists to verify compliance and completeness, offering a structured and straightforward approach to assessments. Diagnostic inspections involve a deeper analysis aimed at identifying root causes of issues and uncovering hidden defects, utilizing expert judgment and adaptive testing methods. The key differences lie in the scope and depth: checklist inspections emphasize consistency and standardization, while diagnostic inspections prioritize problem-solving and detailed evaluation.

Benefits of Checklist Inspections

Checklist inspections ensure consistency and thoroughness by providing a standardized framework that inspectors can follow, reducing the risk of overlooking critical components. These inspections facilitate faster completion times and improve documentation accuracy, streamlining compliance and audit processes. By simplifying training requirements, checklist inspections enable less-experienced personnel to perform reliable assessments, enhancing operational efficiency.

Advantages of Diagnostic Inspections

Diagnostic inspections offer a comprehensive analysis by identifying the root causes of defects rather than just listing visible issues, enabling targeted maintenance and repair. This method improves accuracy in problem detection through advanced tools and techniques, reducing downtime and preventing costly equipment failures. Enhanced data collection during diagnostic inspections supports proactive decision-making and long-term asset management strategies.

When to Choose Checklist Inspection

Choose checklist inspection when routine, standardized evaluations are required to ensure compliance with established protocols or safety regulations. This method is ideal for frequent, repetitive assessments where specific criteria must be consistently verified, such as equipment maintenance or quality control processes. Checklist inspections provide a quick, systematic approach to detect obvious defects or deviations without the need for in-depth analysis.

When to Opt for Diagnostic Inspection

Opt for diagnostic inspection when detailed analysis is required to identify hidden faults or root causes in complex systems, especially after a checklist inspection reveals anomalies. Diagnostic inspections use advanced tools and techniques like thermal imaging and vibration analysis to provide precise data beyond standard checklist parameters. This approach is essential in critical environments where failure consequences are high and preventive maintenance decisions depend on accurate diagnostics.

Common Issues Detected by Each Inspection Type

Checklist inspections frequently identify surface-level issues such as missing components, loose connections, and non-compliance with basic safety standards, enabling quick verification of predefined criteria. Diagnostic inspections delve deeper to detect underlying problems like malfunctioning sensors, software errors, and system performance deviations, which require specialized tools and analysis. Combining both approaches ensures comprehensive assessment by capturing both obvious defects and complex system faults.

Choosing the Right Inspection for Your Vehicle

Choosing the right inspection for your vehicle depends on the goal: a checklist inspection involves a systematic review of specific components such as brakes, tires, and fluid levels to ensure basic safety and compliance. Diagnostic inspection employs advanced tools and software to identify underlying mechanical or electronic issues by analyzing error codes and performance data. Prioritizing checklist inspections for routine maintenance and opting for diagnostic inspections when experiencing vehicle symptoms ensures accurate problem detection and efficient repair.

Checklist inspection vs diagnostic inspection Infographic

cardiffo.com

cardiffo.com