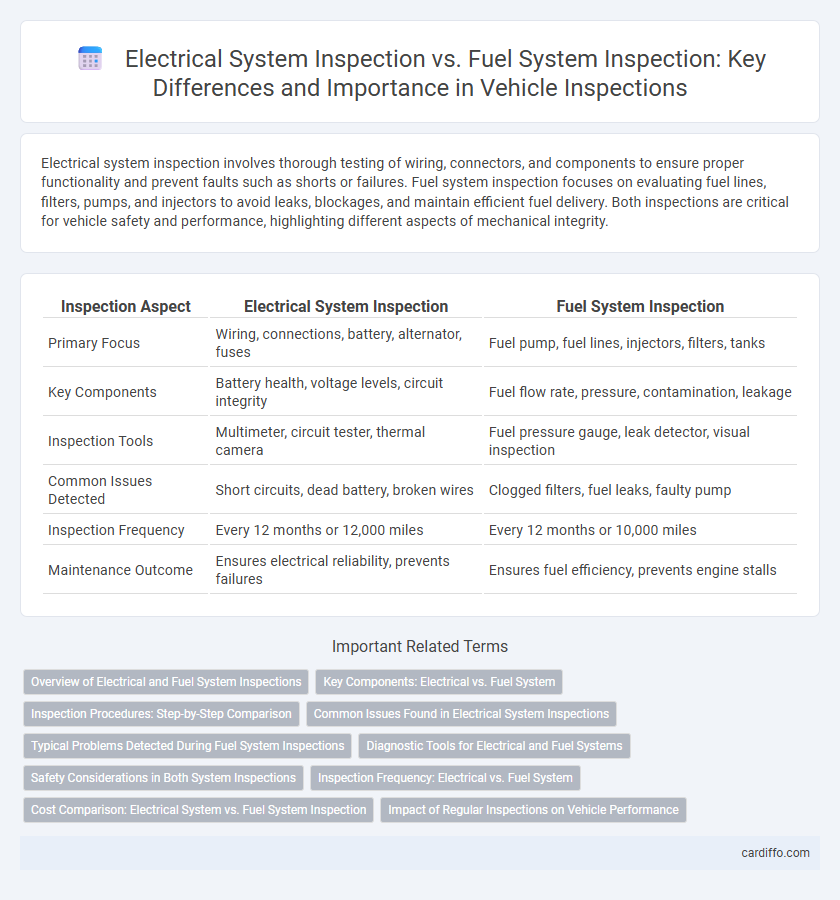

Electrical system inspection involves thorough testing of wiring, connectors, and components to ensure proper functionality and prevent faults such as shorts or failures. Fuel system inspection focuses on evaluating fuel lines, filters, pumps, and injectors to avoid leaks, blockages, and maintain efficient fuel delivery. Both inspections are critical for vehicle safety and performance, highlighting different aspects of mechanical integrity.

Table of Comparison

| Inspection Aspect | Electrical System Inspection | Fuel System Inspection |

|---|---|---|

| Primary Focus | Wiring, connections, battery, alternator, fuses | Fuel pump, fuel lines, injectors, filters, tanks |

| Key Components | Battery health, voltage levels, circuit integrity | Fuel flow rate, pressure, contamination, leakage |

| Inspection Tools | Multimeter, circuit tester, thermal camera | Fuel pressure gauge, leak detector, visual inspection |

| Common Issues Detected | Short circuits, dead battery, broken wires | Clogged filters, fuel leaks, faulty pump |

| Inspection Frequency | Every 12 months or 12,000 miles | Every 12 months or 10,000 miles |

| Maintenance Outcome | Ensures electrical reliability, prevents failures | Ensures fuel efficiency, prevents engine stalls |

Overview of Electrical and Fuel System Inspections

Electrical system inspection involves assessing the vehicle's battery, wiring, alternator, and starter to ensure proper power distribution and prevent malfunctions. Fuel system inspection primarily examines the fuel pump, fuel lines, injectors, and fuel filter to guarantee efficient fuel delivery and combustion. Both inspections are crucial for vehicle performance, safety, and preventing costly repairs by identifying faults within the respective systems.

Key Components: Electrical vs. Fuel System

Electrical system inspection targets key components including wiring harnesses, circuit breakers, fuses, and battery terminals for corrosion or damage, ensuring proper connectivity and functionality. In contrast, fuel system inspection focuses on fuel lines, fuel pump, injectors, and filters to detect leaks, blockages, or wear that could impair fuel delivery and engine performance. Both inspections are crucial for vehicle safety but address distinct elements affecting power distribution versus fuel supply.

Inspection Procedures: Step-by-Step Comparison

Electrical system inspection involves systematically checking wiring integrity, connections, and component functionality using tools like multimeters and circuit testers. Fuel system inspection requires examining fuel lines, filters, pumps, and injectors for leaks, clogs, or wear, often using pressure gauges and visual assessments. Both inspections follow detailed protocols ensuring safety and performance, but electrical inspections prioritize electrical continuity and resistance, while fuel inspections focus on fluid flow and contamination.

Common Issues Found in Electrical System Inspections

Common issues found in electrical system inspections include corroded connections, worn-out wiring insulation, and faulty circuit breakers that can lead to intermittent power loss or complete system failure. Inspectors frequently identify loose terminals and damaged fuses causing disruptions in electrical flow and safety hazards. Regular checks for voltage irregularities and compromised grounding enhance reliability and prevent fire risks in electrical systems.

Typical Problems Detected During Fuel System Inspections

Fuel system inspections commonly reveal issues such as clogged fuel filters, fuel line leaks, and malfunctioning fuel injectors that can lead to poor engine performance and reduced fuel efficiency. Detecting contaminated fuel or vapor lock conditions is crucial to prevent engine stalling and potential safety hazards. Unlike electrical system inspections that focus on wiring faults and battery health, fuel system inspections prioritize identifying fuel delivery problems and ensuring proper fuel pressure regulation.

Diagnostic Tools for Electrical and Fuel Systems

Diagnostic tools for electrical system inspection primarily include multimeters, oscilloscopes, and circuit testers, enabling precise measurement of voltage, current, and resistance to identify faults such as short circuits or open circuits. Fuel system inspections utilize fuel pressure gauges, fuel flow meters, and electronic diagnostic scanners to detect issues like fuel leaks, clogged injectors, or pump failures by analyzing fuel pressure and flow parameters. Advanced diagnostic software can integrate data from both electrical and fuel systems, facilitating comprehensive fault analysis and ensuring optimal engine performance.

Safety Considerations in Both System Inspections

Electrical system inspection prioritizes detecting wiring faults, insulation damage, and potential short circuits that could pose fire or shock hazards, ensuring the safety of both personnel and equipment. Fuel system inspection emphasizes identifying leaks, vapor buildup, and faulty seals to prevent fire risks and toxic exposure, which are critical for avoiding explosions and environmental contamination. Both inspections demand rigorous adherence to safety protocols, proper use of protective gear, and thorough testing to mitigate risks inherent in electrical and fuel systems.

Inspection Frequency: Electrical vs. Fuel System

Electrical system inspections typically require more frequent attention, often every 6 to 12 months, due to the complexity and critical safety role of wiring, batteries, and circuit components. Fuel system inspections, while equally vital, are generally conducted less often, approximately every 12 to 24 months, focusing on fuel lines, filters, and tanks to prevent leaks and contamination. Properly scheduled inspections based on these frequencies ensure operational reliability and prevent costly system failures.

Cost Comparison: Electrical System vs. Fuel System Inspection

Electrical system inspections typically cost between $100 and $200, focusing on battery health, wiring, and component functionality. Fuel system inspections range from $150 to $250, covering fuel pump performance, fuel filter condition, and injector efficiency. The higher cost for fuel system inspections reflects the complexity and labor involved in accessing and testing fuel components.

Impact of Regular Inspections on Vehicle Performance

Regular electrical system inspections detect issues like faulty wiring or battery degradation that can cause engine misfires and decreased fuel efficiency. Fuel system inspections identify clogged injectors or leaks that directly affect combustion quality and power output. Consistent maintenance of both systems enhances overall vehicle reliability, reduces breakdown risks, and optimizes fuel economy for improved performance.

Electrical system inspection vs fuel system inspection Infographic

cardiffo.com

cardiffo.com