Catalytic converter efficiency primarily depends on its ability to oxidize carbon monoxide and hydrocarbons while reducing nitrogen oxides, using a platinum group metal catalyst. Selective Catalytic Reduction (SCR) enhances nitrogen oxide reduction by injecting a reductant, such as ammonia or urea, into the exhaust stream to convert NOx into nitrogen and water. SCR systems generally achieve higher NOx reduction rates compared to conventional catalytic converters, especially in diesel engines, improving overall emission control.

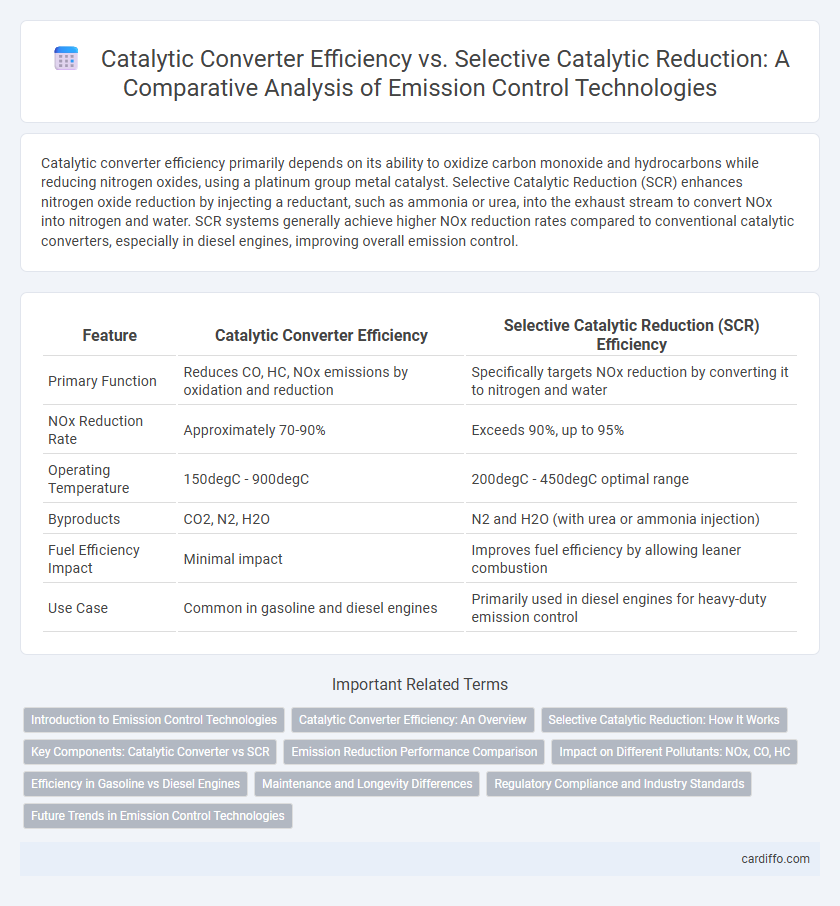

Table of Comparison

| Feature | Catalytic Converter Efficiency | Selective Catalytic Reduction (SCR) Efficiency |

|---|---|---|

| Primary Function | Reduces CO, HC, NOx emissions by oxidation and reduction | Specifically targets NOx reduction by converting it to nitrogen and water |

| NOx Reduction Rate | Approximately 70-90% | Exceeds 90%, up to 95% |

| Operating Temperature | 150degC - 900degC | 200degC - 450degC optimal range |

| Byproducts | CO2, N2, H2O | N2 and H2O (with urea or ammonia injection) |

| Fuel Efficiency Impact | Minimal impact | Improves fuel efficiency by allowing leaner combustion |

| Use Case | Common in gasoline and diesel engines | Primarily used in diesel engines for heavy-duty emission control |

Introduction to Emission Control Technologies

Catalytic converters reduce harmful vehicle emissions by converting carbon monoxide, hydrocarbons, and nitrogen oxides into less toxic gases through oxidation and reduction reactions. Selective Catalytic Reduction (SCR) specifically targets nitrogen oxides (NOx) using a urea-based additive, achieving higher NOx reduction efficiency than conventional catalytic converters. Both technologies play critical roles in meeting stringent emission standards, with SCR offering advanced control for diesel engines and catalytic converters widely used in gasoline vehicles.

Catalytic Converter Efficiency: An Overview

Catalytic converter efficiency primarily depends on its ability to convert harmful gases such as carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx) into less toxic substances like carbon dioxide (CO2), water (H2O), and nitrogen (N2). The efficiency is influenced by factors including catalyst composition, operating temperature, and exhaust gas flow rate, with platinum, palladium, and rhodium commonly used as active materials. State-of-the-art catalytic converters achieve conversion efficiencies exceeding 90% under optimal conditions, significantly reducing vehicular emissions.

Selective Catalytic Reduction: How It Works

Selective Catalytic Reduction (SCR) reduces nitrogen oxide (NOx) emissions by injecting a urea-based solution, commonly known as diesel exhaust fluid (DEF), into the exhaust stream. This chemical reaction occurs inside the SCR catalyst, where NOx is converted into harmless nitrogen (N2) and water vapor (H2O), significantly lowering vehicle emissions. SCR systems offer higher nitrogen oxide removal efficiency compared to traditional catalytic converters, especially in diesel engines under varied operating conditions.

Key Components: Catalytic Converter vs SCR

Catalytic converters primarily use platinum, palladium, and rhodium as key components to facilitate the oxidation of carbon monoxide and hydrocarbons into less harmful emissions. In contrast, Selective Catalytic Reduction (SCR) systems rely on a catalyst, typically made from titanium dioxide or zeolite, combined with a urea-based reductant to convert nitrogen oxides (NOx) into nitrogen and water. The distinct chemical mechanisms and component compositions define the efficiency differences in reducing specific pollutants between catalytic converters and SCR systems.

Emission Reduction Performance Comparison

Catalytic converters reduce emissions by converting harmful gases such as carbon monoxide, hydrocarbons, and nitrogen oxides into less harmful substances through oxidation and reduction reactions. Selective Catalytic Reduction (SCR) systems specifically target nitrogen oxides (NOx) emissions in diesel engines by injecting a urea-based solution to convert NOx into nitrogen and water, achieving up to 90% NOx reduction. While catalytic converters provide broad-spectrum emission treatment, SCR systems excel in reducing NOx emissions, making them more effective for stringent NOx regulations in heavy-duty vehicles.

Impact on Different Pollutants: NOx, CO, HC

Catalytic converters effectively reduce carbon monoxide (CO) and hydrocarbons (HC) by oxidizing these pollutants into less harmful compounds but have limited efficiency in reducing nitrogen oxides (NOx). Selective Catalytic Reduction (SCR) systems specialize in decreasing NOx emissions by converting them into nitrogen and water through the injection of a urea-based reductant, achieving reductions of up to 90%. Combining catalytic converters with SCR provides comprehensive emission control, significantly improving air quality by targeting CO, HC, and NOx pollutants simultaneously.

Efficiency in Gasoline vs Diesel Engines

Catalytic converter efficiency in gasoline engines typically ranges from 85% to 95% in reducing carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx), due to the stoichiometric air-fuel mixture that promotes optimal oxidation and reduction reactions. Selective Catalytic Reduction (SCR) in diesel engines achieves NOx reduction efficiencies exceeding 90% by injecting urea-based reductants into the exhaust stream, compensating for the lean burn conditions that hinder traditional catalytic converters. Diesel engines benefit more from SCR systems for NOx control, while gasoline engines rely primarily on three-way catalytic converters for balanced emission reduction.

Maintenance and Longevity Differences

Catalytic converters require less frequent maintenance due to their simpler structure but can degrade faster under high pollutant loads, impacting long-term efficiency. Selective Catalytic Reduction (SCR) systems demand regular replenishment of urea-based reductants and more complex upkeep, which extends their operational lifespan and maintains higher NOx reduction efficiency. SCR technology ultimately offers greater longevity and consistent performance in controlling emissions compared to traditional catalytic converters.

Regulatory Compliance and Industry Standards

Catalytic converter efficiency is critical for meeting stringent regulatory compliance, effectively reducing carbon monoxide, hydrocarbons, and nitrogen oxides within emission limits set by agencies such as the EPA and Euro standards. Selective Catalytic Reduction (SCR) systems surpass traditional converters by targeting NOx reduction through ammonia injection, aligning with Tier 4 and Euro 6 emission standards for heavy-duty vehicles. Industry standards prioritize SCR technology for its superior NOx control, ensuring vehicles comply with evolving regulations and reduce environmental impact.

Future Trends in Emission Control Technologies

Catalytic converter efficiency is advancing with enhanced precious metal formulations, improving oxidation and reduction reactions that reduce CO, HC, and NOx emissions. Selective Catalytic Reduction (SCR) systems are evolving through optimized urea injection and catalyst materials, achieving greater NOx conversion rates under diverse operating conditions. Future trends emphasize integration of real-time emission monitoring and adaptive catalyst management to meet increasingly stringent global emission standards.

Catalytic Converter Efficiency vs Selective Catalytic Reduction Infographic

cardiffo.com

cardiffo.com